Tsarin Bushewar Abu Mai Girma

Tsarin Bushewar Abu Mai Girma

Bayanin Material

Hanyar da aka fi amfani da ita wajen zubar da taki a gargajiyance ita ce sayar da taki na gonaki tare da rahusa kuma a yi amfani da shi kai tsaye a matsayin takin noma, darajar tattalin arzikinsa ba za a yi cikakken bincike da amfani da shi ba.A haƙiƙa, waɗannan su ne albarkatu masu daraja da kiwo da takin zamani, idan za a iya haɓakawa kuma a yi amfani da su, za su kasance suna da mahimmaci ga masana'antar takin zamani, da bunƙasa masana'antar shuka da kiwo, don haɓaka samar da noma da samun kuɗin shiga, ceton makamashi da samar da makamashi da kuma samar da makamashi. Koren abinci mara gurɓatacce, koren ci gaban noma, don kare muhalli da lafiyar mutane.

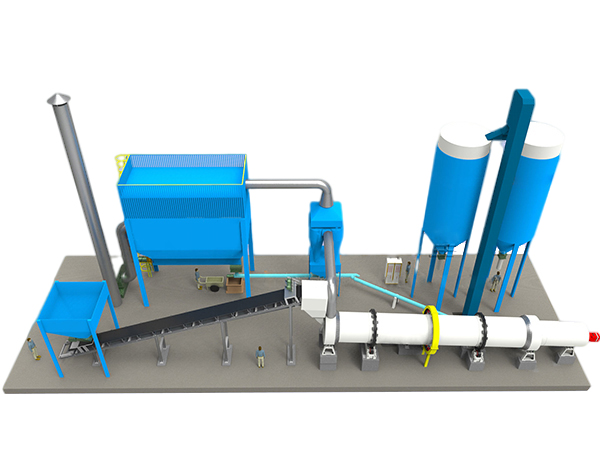

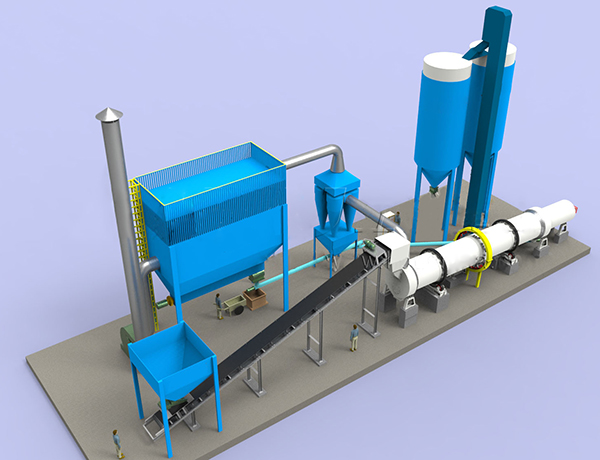

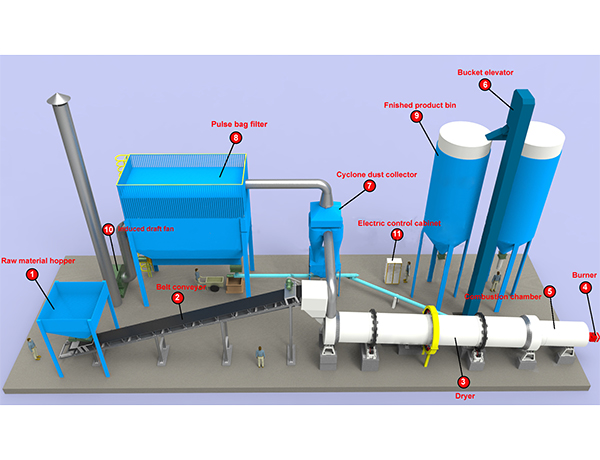

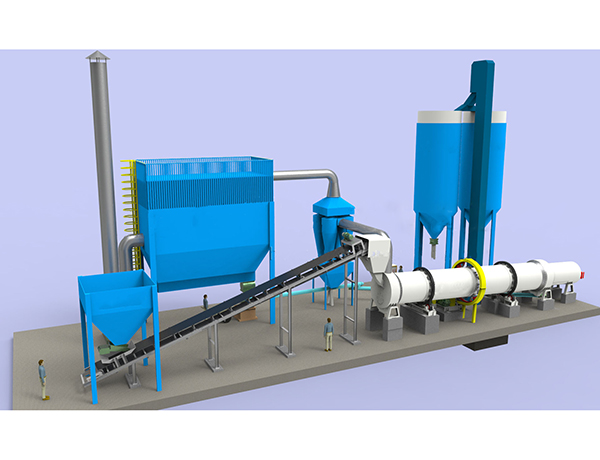

Tsarin Tsari

Za a kai kayan da ba su da ruwa zuwa wurin ciyar da na'urar bushewa ta hanyar jigilar kaya bayan watsawa, sa'an nan kuma za a aika shi cikin cikin na'urar bushewa ta hanyar mai ba da kariya ta karkace mara ƙarfi (fasaha na haƙƙin mallaka na kamfaninmu), kuma ta hanyar da yawa. bin wuraren aiki bayan shiga cikin na'urar bushewa:

1. Material jagoranci-in yankin

Kayan zai shiga cikin hulɗa tare da iska mai zafi mara kyau bayan shiga cikin wannan yanki kuma za a kwashe ruwa da yawa da sauri, kuma kayan ba za a iya kafa su cikin abubuwa masu ɗorewa ba a ƙarƙashin motsawar babban kusurwar ɗagawa.

2. Wurin tsaftacewa

Za a samar da labulen kayan yayin da aka ɗaga sludge sama a wannan yanki, kuma zai sa kayan ya tsaya a bangon Silinda yayin da yake faɗuwa, kuma ana shigar da na'urar tsaftacewa a wannan yanki (Salon ɗagawa, nau'in X na biyu na biyu). farantin motsa jiki na lokaci, sarkar tasiri, farantin karfe), za'a iya cire kayan da sauri daga bangon silinda ta na'urar tsaftacewa, kuma na'urar tsaftacewa na iya murkushe kayan da aka haɗa tare, don ƙara yawan yankin musayar zafi, karuwa. lokacin musayar zafi, kauce wa tsarar yanayin ramin iska, inganta yawan bushewa;

3. Wurin ɗagawa mai karkata

Wannan yanki shine wurin bushewa mai ƙarancin zafin jiki, slime na wannan yanki yana cikin ƙarancin ɗanɗano da sako-sako, kuma babu wani abu mai mannewa a wannan yanki, samfuran da aka gama sun isa buƙatun danshi bayan musayar zafi, sannan shigar da ƙarshe. wurin fitarwa;

4. Wurin fitarwa

Babu faranti masu motsawa a wannan yanki na silinda mai bushewa, kuma kayan za su kasance suna jujjuya zuwa tashar jiragen ruwa.Abun a hankali ya zama sako-sako bayan bushewa, kuma a fitar da shi daga ƙarshen fitarwa, sannan a aika zuwa wurin da aka keɓe ta na'urar isar da sako, kuma ƙurar ƙurar da aka zana tare da iskar gas ɗin wutsiya ana tattara ta ta hanyar mai tara ƙura.

Iska mai zafi yana shiga cikin injin bushewa daga ƙarshen ciyarwa, kuma ana rage yawan zafin jiki a hankali a lokaci guda na canja wurin zafi na abu, da tururi na ruwa da aka fitar a ƙarƙashin shayar da fan ɗin da aka jawo, sa'an nan kuma fitar dashi cikin iska bayan sarrafawa. .

Amfanin Tsarin

Babban ingancin thermal, ƙananan farashin bushewa

Sabon tsarin ciki, da ƙarfafa tsaftacewa na kayan da aka tarwatsa da zafin zafi, kawar da abin da ya faru na bangon ganga na jikin ganga, ya fi dacewa da kayan daɗaɗɗa da danshi, wurin musayar zafi da kuma bushewa yadda ya dace.Za'a iya canza sigogin aiki bisa ga kayan daban-daban, kuma musayar zafi na kayan a cikin na'urar bushewa ya fi cikakke.

Amintaccen gudu, kwanciyar hankali mai kyau

Sabon nau'in ciyarwa da na'urar fitarwa, ya kawo ƙarshen abin da ke faruwa na toshewa a cikin ciyarwa, rashin ci gaba, nonuniform da dawowar kayan.Na'urar bushewa tana ɗaukar "aligning roller na'urar", wanda ke sa ƙwanƙwasa da na'ura mai jujjuyawa koyaushe suna yin layin layi, kuma yana rage lalata da amfani da wutar lantarki sosai. da abrasion na gear dabaran da goyon bayan dabaran, da Silinda aiki ya fi barga da kuma abin dogara.

Faɗin kewayon tushen zafi ta amfani da, kariyar muhalli da rashin gurɓatawa

Ana iya amfani da gawayi, mai, iskar gas, iskar gas mai ruwa da tsaki a matsayin mai.An ƙaddara bisa ga buƙatun kayan aiki da fa'idodin yanayi na gida, don haɓaka ingantaccen samarwa da fa'idodin tattalin arziki.

Babban matakin sarrafa kansa, tsaro na lokaci-lokaci

Za'a iya ɗaukar tsarin sarrafawa ta atomatik na PLC a cikin dukkan tsarin, tsarin ya ƙunshi kayan aikin gwaji na ci gaba: ma'aunin zafin jiki, tsarin zafin jiki (ana iya daidaita shi a kowane lokaci bisa ga buƙatun kayan), aikin ƙararrawar kuskure ta atomatik, atomatik. kariyar kashewa, da sauransu.

Ma'aunin Fasaha

| Samfura | Diamita na Silinda (mm) | Tsawon Silinda (mm) | Girman Silinda (m3) | Gudun juyi na Silinda (r/min) | Ƙarfi (kW) | Nauyi(t) |

| VS 0.6x5.8 | 600 | 5800 | 1.7 | 1-8 | 3 | 2.9 |

| VS 0.8x8 | 800 | 8000 | 4 | 1-8 | 4 | 3.5 |

| VS 1x10 | 1000 | 10000 | 7.9 | 1-8 | 5.5 | 6.8 |

| VS 1.2x5.8 | 1200 | 5800 | 6.8 | 1-6 | 5.5 | 6.7 |

| VS 1.2x8 | 1200 | 8000 | 9 | 1-6 | 5.5 | 8.5 |

| VS 1.2x10 | 1200 | 10000 | 11 | 1-6 | 7.5 | 10.7 |

| VS 1.2x11.8 | 1200 | 11800 | 13 | 1-6 | 7.5 | 12.3 |

| VS 1.5x8 | 1500 | 8000 | 14 | 1-5 | 11 | 14.8 |

| VS 1.5x10 | 1500 | 10000 | 17.7 | 1-5 | 11 | 16 |

| VS 1.5x11.8 | 1500 | 11800 | 21 | 1-5 | 15 | 17.5 |

| VS 1.5x15 | 1500 | 15000 | 26.5 | 1-5 | 15 | 19.2 |

| VS 1.8x10 | 1800 | 10000 | 25.5 | 1-5 | 15 | 18.1 |

| VS 1.8x11.8 | 1800 | 11800 | 30 | 1-5 | 18.5 | 20.7 |

| VS 1.8x15 | 1800 | 15000 | 38 | 1-5 | 18.5 | 26.3 |

| VS 1.8x18 | 1800 | 18000 | 45.8 | 1-5 | 22 | 31.2 |

| VS 2x11.8 | 2000 | 11800 | 37 | 1-4 | 18.5 | 28.2 |

| VS 2x15 | 2000 | 15000 | 47 | 1-4 | 22 | 33.2 |

| VS 2x18 | 2000 | 18000 | 56.5 | 1-4 | 22 | 39.7 |

| VS 2x20 | 2000 | 20000 | 62.8 | 1-4 | 22 | 44.9 |

| VS 2.2x11.8 | 2200 | 11800 | 44.8 | 1-4 | 22 | 30.5 |

| VS 2.2x15 | 2200 | 15000 | 53 | 1-4 | 30 | 36.2 |

| VS 2.2x18 | 2200 | 18000 | 68 | 1-4 | 30 | 43.3 |

| VS 2.2x20 | 2200 | 20000 | 76 | 1-4 | 30 | 48.8 |

| VS 2.4x15 | 2400 | 15000 | 68 | 1-4 | 30 | 43.7 |

| VS 2.4x18 | 2400 | 18000 | 81 | 1-4 | 37 | 53 |

| VS 2.4x20 | 2400 | 20000 | 91 | 1-4 | 37 | 60.5 |

| VS 2.4x23.6 | 2400 | 23600 | 109 | 1-4 | 45 | 69.8 |

| VS 2.8x18 | 2800 | 18000 | 111 | 1-3 | 45 | 62 |

| VS 2.8x20 | 2800 | 20000 | 123 | 1-3 | 55 | 65 |

| VS 2.8x23.6 | 2800 | 23600 | 148 | 1-3 | 55 | 70 |

| VS 2.8x28 | 2800 | 28000 | 172 | 1-3 | 75 | 75 |

| VS 3x20 | 3000 | 20000 | 141 | 1-3 | 55 | 75 |

| VS 3x23.6 | 3000 | 23600 | 170 | 1-3 | 75 | 85 |

| VS 3x28 | 3000 | 28000 | 198 | 1-3 | 90 | 91 |

| VS 3.2x23.6 | 3200 | 23600 | 193 | 1-3 | 90 | 112 |

| VS 3.2x32 | 3200 | 32000 | 257 | 1-3 | 110 | 129 |

| VS 3.6x36 | 3600 | 36000 | 366 | 1-3 | 132 | 164 |

| VS 3.8x36 | 3800 | 36000 | 408 | 1-3 | 160 | 187 |

| VS 4x36 | 4000 | 36000 | 452 | 1-3 | 160 | 195 |

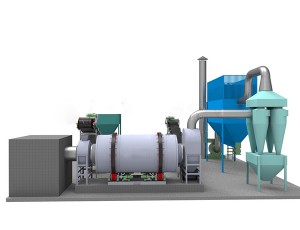

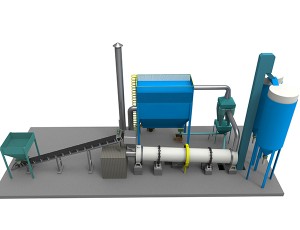

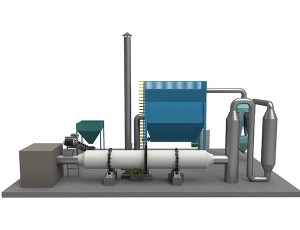

Hotunan Rukunan Aiki