Tsarin Samar da Bushewar Kayan Haske

Tsarin Samar da Bushewar Kayan Haske

Gabatarwa Tsarin

A cikin 'yan shekarun nan, tare da karuwar albarkatun muhalli, cikakken amfani da makamashin halittu ya zama mafi mahimmanci a gare mu.Saboda yawan damshin da ke tattare da sawdust, karyewar itace, wanda ke haifar da konewar da ba ta cika ba, wanda hakan ya sa tartsatsin ke kona jakar kurar da ke bayan injin bushewar, wanda ba wai kawai ke haifar da fitar da iska mai yawa ba, har ma yana da tsada. don canza jakar kura.A cikin aiwatar da samar da kayan itace da makamashin biomass tare da ƙimar konewa mai yawa, guntuwar itace da fashe-fashe ana buƙatar yin aikin bushewa.

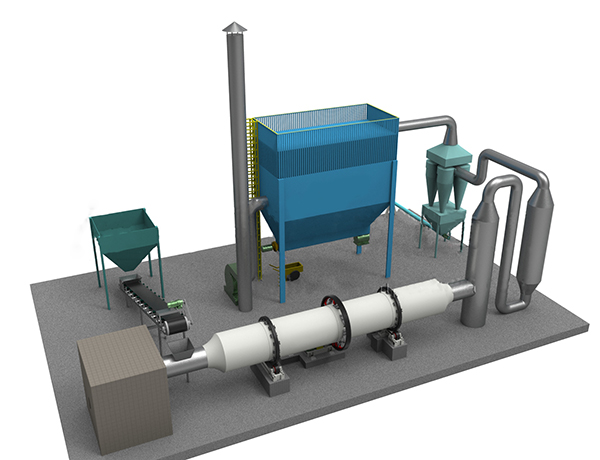

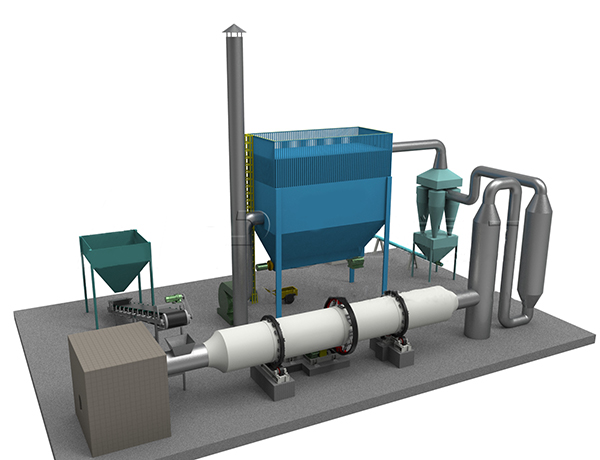

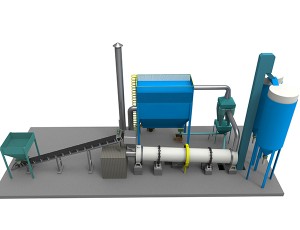

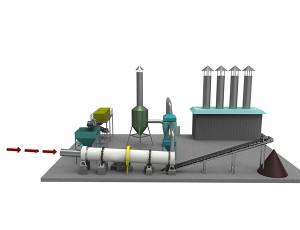

Tsarin Tsari

Bayan an ciyar da shi a cikin hopper, ƙarƙashin aikin nauyi, albarkatun ƙasa za su faɗo a kan bel ɗin da aka shimfiɗa a ƙarƙashin kasan hopper, sa'an nan kuma wanda za a kai shi kan na'urar tantancewa, babban, tsiri da sauran kayan da ba su dace ba. An rabu da su bayan an nuna, kuma za a isar da ɓangarorin uniform zuwa ƙarshen ciyarwar na'urar bushewa (Za'a zaɓi na'urar bushewa ɗaya ko na'urar bushewa uku kamar yadda yanayin sabis) ta hanyar jigilar bel ɗin ƙarƙashin injin nunawa.An haɗa ƙarshen ciyarwar na'urar bushewa tare da tushen zafi kuma an haɗa ƙarshen fitarwa tare da bututun iska.Za a kafa bangon wuta a cikin murhu mai zafi don tabbatar da amincin tsarin bushewa, don kawar da abin da ke faruwa na kayan da ke ƙonewa a cikin na'urar bushewa, kuma za a shigar da zafin da ke wucewa ta cikin bututu tsakanin murhun fashewa mai zafi da na'urar bushewa a matsayin sashin buffer zafi.Za a shigar da kayan a cikin bututun bugun jini da aka canza diamita bayan an bushe shi da bushewa a karon farko a cikin na'urar bushewa, wanda zai kasance a cikin sigar tafasa mai tsayi a babban diamita na bututun bugun jini, sannan za a bushe da sauri. bayan tuntuɓar iska mai zafi daga na'urar bushewa.Kuma za a fitar da kayan daga cikin bututun bugun iska ta hanyar iska mai ƙarfi sannan a motsa shi zuwa matakin farko na masu tara guguwa lokacin da abin da ke cikin ruwa ya kai ga yadda ake buƙata, kuma za a tattara kashi 80% na busassun busassun, sannan a shiga mataki na biyu. bayan wucewa ta hanyar daftarin da aka jawo don tattara kayan hagu.Za'a iya maye gurbin mai tara iskar guguwa mataki na biyu da mai tara kura irin na jaka.

Amfanin Tsarin

Ƙarfin bushewa mai ƙarfi tare da ɗan gajeren lokacin bushewa

Tsarin bushewa na kayan haske yana da ƙira mai mahimmanci, wanda ya bar kayan yana da cikakkiyar lamba a cikin na'urar bushewa, cikakken yanki na barbashi shine wurin bushewa mai tasiri, kuma yana da ƙarfin bushewa.Tare da na'urar bushewa ta bugun iska, lokacin bushewa shine kawai rabin na'urar bushewa na yau da kullun, ingancin injin bushewa yana ƙaruwa sosai.

Ƙananan farashin bushewa tare da ingantaccen bushewa

Tsarin bushewa na kayan haske yana da tsarin ci gaba, tare da ƙaramin yanki da aka rufe, mai sauƙin ginawa da kuma kiyayewa.Ingantacciyar thermal na iya kaiwa 90% lokacin da ya bushe ruwan da ba a ɗaure ba.

Kyakkyawan tasirin bushewa tare da babban matakin aiki da kai

Danshi na ƙarshe yana da ƙarfi (10% -13%) bayan an bushe kayan haske na yau da kullun, kuma busasshen abu bai ƙunshi ƙazanta ba.Za a iya daidaita murhu mai zafi da ƙararrawar zafin jiki, na'urar lura da harshen wuta, ƙararrawa mai zafi, na'urar keɓe mai, wanda zai iya tabbatar da amincin konewa.

Ma'aunin Fasaha

| Samfura | Diamita na Silinda (mm) | Tsawon Silinda (mm) | Girman Silinda (m3) | Gudun juyi na Silinda (r/min) | Ƙarfi (kW) | Nauyi(t) |

| VS0.6x5.8 | 600 | 5800 | 1.7 | 1-8 | 3 | 2.9 |

| VS0.8x8 | 800 | 8000 | 4 | 1-8 | 4 | 3.5 |

| VS1x10 | 1000 | 10000 | 7.9 | 1-8 | 5.5 | 6.8 |

| VS1.2x5.8 | 1200 | 5800 | 6.8 | 1-6 | 5.5 | 6.7 |

| VS1.2x8 | 1200 | 8000 | 9 | 1-6 | 5.5 | 8.5 |

| VS1.2x10 | 1200 | 10000 | 11 | 1-6 | 7.5 | 10.7 |

| VS1.2x11.8 | 1200 | 11800 | 13 | 1-6 | 7.5 | 12.3 |

| VS1.5x8 | 1500 | 8000 | 14 | 1-5 | 11 | 14.8 |

| VS1.5x10 | 1500 | 10000 | 17.7 | 1-5 | 11 | 16 |

| VS1.5x11.8 | 1500 | 11800 | 21 | 1-5 | 15 | 17.5 |

| VS1.5x15 | 1500 | 15000 | 26.5 | 1-5 | 15 | 19.2 |

| VS1.8x10 | 1800 | 10000 | 25.5 | 1-5 | 15 | 18.1 |

| VS1.8x11.8 | 1800 | 11800 | 30 | 1-5 | 18.5 | 20.7 |

| VS1.8x15 | 1800 | 15000 | 38 | 1-5 | 18.5 | 26.3 |

| VS1.8x18 | 1800 | 18000 | 45.8 | 1-5 | 22 | 31.2 |

| VS2x11.8 | 2000 | 11800 | 37 | 1-4 | 18.5 | 28.2 |

| VS2x15 | 2000 | 15000 | 47 | 1-4 | 22 | 33.2 |

| VS2x18 | 2000 | 18000 | 56.5 | 1-4 | 22 | 39.7 |

| VS2x20 | 2000 | 20000 | 62.8 | 1-4 | 22 | 44.9 |

| VS2.2x11.8 | 2200 | 11800 | 44.8 | 1-4 | 22 | 30.5 |

| VS2.2x15 | 2200 | 15000 | 53 | 1-4 | 30 | 36.2 |

| VS2.2x18 | 2200 | 18000 | 68 | 1-4 | 30 | 43.3 |

| VS2.2x20 | 2200 | 20000 | 76 | 1-4 | 30 | 48.8 |

| VS2.4x15 | 2400 | 15000 | 68 | 1-4 | 30 | 43.7 |

| VS2.4x18 | 2400 | 18000 | 81 | 1-4 | 37 | 53 |

| VS2.4x20 | 2400 | 20000 | 91 | 1-4 | 37 | 60.5 |

| VS2.4x23.6 | 2400 | 23600 | 109 | 1-4 | 45 | 69.8 |

| VS2.8x18 | 2800 | 18000 | 111 | 1-3 | 45 | 62 |

| VS2.8x20 | 2800 | 20000 | 123 | 1-3 | 55 | 65 |

| VS2.8x23.6 | 2800 | 23600 | 148 | 1-3 | 55 | 70 |

| VS2.8x28 | 2800 | 28000 | 172 | 1-3 | 75 | 75 |

| VS3x20 | 3000 | 20000 | 141 | 1-3 | 55 | 75 |

| VS3x23.6 | 3000 | 23600 | 170 | 1-3 | 75 | 85 |

| VS3x28 | 3000 | 28000 | 198 | 1-3 | 90 | 91 |

| VS3.2x23.6 | 3200 | 23600 | 193 | 1-3 | 90 | 112 |

| VS3.2x32 | 3200 | 32000 | 257 | 1-3 | 110 | 129 |

| VS3.6x36 | 3600 | 36000 | 366 | 1-3 | 132 | 164 |

| VS3.8x36 | 3800 | 36000 | 408 | 1-3 | 160 | 187 |

| VS4x36 | 4000 | 36000 | 452 | 1-3 | 160 | 195 |

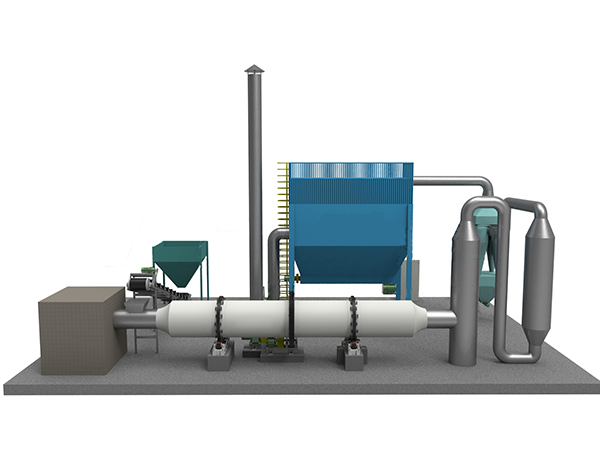

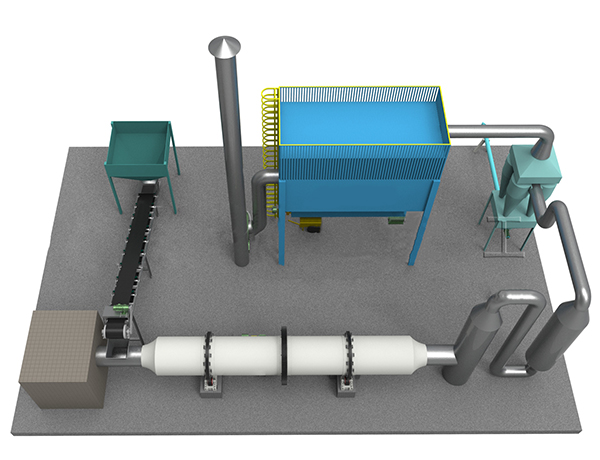

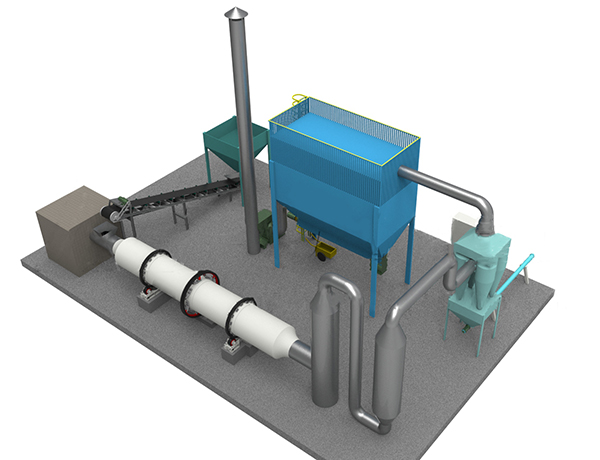

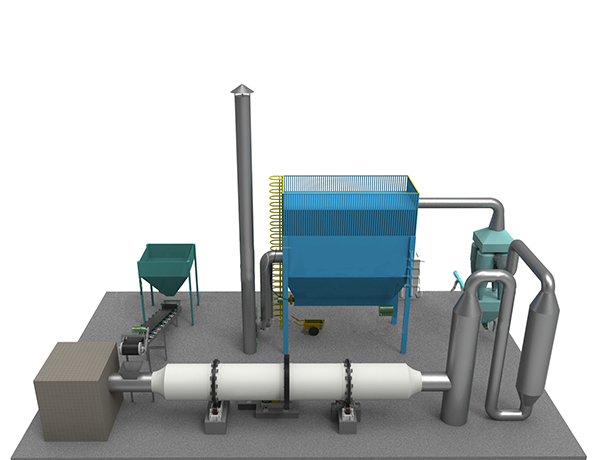

Hotunan Rukunan Aiki