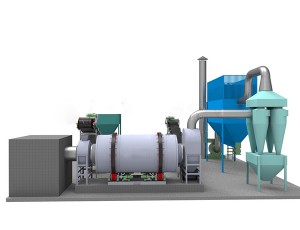

Silinda Uku ko Drum Drum

Silinda Uku ko Drum Drum

Halayen Aiki

1. Ƙananan zafin jiki na iska, tsawon rayuwar sabis na kayan cire ƙura.

2. Girman kayan dunƙule, barbashi, da foda suna ƙasa da 20mm ana iya bushewa.

3. Ba a buƙatar tuƙi na Gear kuma kai tsaye ne ke jagorantar shi ta hanyar abin nadi, tare da ingantaccen injin inji.

4. Ba tare da abin mamaki na yayyo iska ba, an warware wahalar rufewa gaba ɗaya, kuma ana iya gama shigarwa cikin sa'o'i kaɗan.

5. An rage kashi 50% na murfin yanki idan aka kwatanta da na'urar bushewa guda ɗaya, kuma an rage zuba jarin ƙasa da kashi 50%, amfani da wutar lantarki ya ragu da kashi 60%.

6. Ingantacciyar thermal mai ɗorewa ta na'urar busar da silinda guda uku na iya kaiwa sama da 70% (na'urar busar daɗaɗɗen zafin jiki na gargajiya guda ɗaya kawai 35%), yana da tasirin ceton makamashi mai ban mamaki.

7. Ana iya daidaita alamun danshi na ƙarshe cikin sauƙi bisa ga buƙatar.

8. Kasa da 1% na danshi na kayan abu zai iya tabbatar da busassun silinda guda uku, wanda shine samfurin da aka fi so don busassun busassun turmi da kuma layin samar da foda.

9. Zazzabi na kayan da aka fitar shine <50 ℃, wanda za'a iya kai tsaye kai tsaye zuwa cikin silo na ajiya, ba lallai ba ne don kwantar da hankali a cikin zubar da sanyi.

Ƙa'idar Aiki

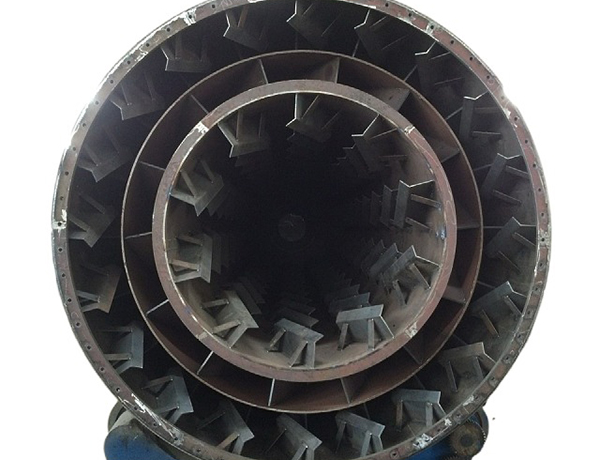

Kayan aiki suna shiga cikin drum na jujjuyawar ciki daga na'urar ciyarwa, don gane bushewa na ƙasa, ana ɗaga kayan sama da ƙasa koyaushe ta faranti na ɗagawa na ciki kuma ana samun canjin zafi a ƙarƙashin hanyar karkace motsi, kayan suna motsawa zuwa wancan gefe. na Silinda na ciki sannan a shiga tsakiyar Silinda, sannan kayan ana ɗaga sama ana matsar da su gaba a tsakiyar Silinda, ta hanyar matakai biyu gaba da mataki ɗaya baya, kayan suna ɗaukar zafi duka suna fitowa daga silinda na ciki da na tsakiya. Silinda, a halin yanzu, lokacin bushewa yana tsawaita, kuma kayan sun kai matsayin bushewa mafi kyau a wannan matakin.Material yana motsa sauran ƙarshen silinda na tsakiya sannan ya shiga cikin silinda na waje, busassun kayan ana fitar da su da sauri daga silinda ƙarƙashin aikin iska mai zafi.

Ma'aunin Fasaha

| Samfura | Silinda bayanai | Iyawa (t/h) | Gudun juzu'i na Silinda (r/min) | Ƙarfi (kW) | ||||

| Silinda diamita na waje (m) | Tsawon Silinda na waje (m) | Girman Silinda (m3) | Kogin yashi | Tashi toka | Slag | |||

| VS6203 | 1.6 | 1.8 | 3.6 | 2-3 | 1-2 | 1-2 | 3-10 | 4 |

| VS6205 | 2 | 2 | 6.28 | 4-5 | 2-3 | 3-4 | 3-10 | 5.5 |

| VS6210 | 2.2 | 2.5 | 9.5 | 8-10 | 4-5 | 6-8 | 3-10 | 7.5 |

| VS6215 | 2.5 | 2.8 | 13.7 | 12-15 | 7-8 | 10-12 | 3-10 | 11 |

| VS2x4 | 2 | 4 | 12.56 | 8-12 | 4-6 | 8-10 | 3-10 | 3 x2 |

| VS2x5 | 2 | 5 | 15.7 | 12-15 | 6-7 | 10-13 | 3-10 | 4 x2 |

| VS2x6 | 2 | 6 | 18.84 | 20-25 | 10-17 | 20-27 | 3-10 | 7.5x2 |

| VS2.2x4.5 | 2.2 | 4.5 | 17.09 | 14-18 | 7-9 | 12-15 | 3-10 | 5.5x2 |

| VS2.5x6 | 2.5 | 6.5 | 31.89 | 23-28 | 10-13 | 20-22 | 3-10 | 5.5x4 |

| VS2.7x7 | 2.7 | 7 | 40.5 | 30-35 | 20-25 | 27-45 | 3-10 | 7.5x4 |

| VS2.8x6 | 2.8 | 6 | 36.9 | 30-35 | 15-18 | 25-30 | 3-10 | 5.5x4 |

| VS3x6 | 3 | 6 | 42.39 | 35-40 | 18-20 | 32-35 | 3-10 | 7.5x4 |

| VS3x7 | 3 | 7 | 49.46 | 40-45 | 20-25 | 35-40 | 3-10 | 7.5x4 |

| VS3.2x7 | 3.2 | 7 | 56.26 | 45-50 | 25-30 | 40-45 | 3-10 | 11 x4 |

| VS3.2x8 | 3.2 | 8 | 64.3 | 50-55 | 30-35 | 45-50 | 3-10 | 11 x4 |

| VS3.6x8 | 3.6 | 8 | 81.38 | 60-70 | 35-40 | 60-65 | 3-10 | 15 x4 |

| VS3.8x9 | 3.8 | 9 | 102 | 70-80 | 40-45 | 70-75 | 3-10 | 15 x4 |

| VS4x10 | 4 | 10 | 125.6 | 90-100 | 45-50 | 80-90 | 3-10 | 18.5x4 |

| VS4.2x8.5 | 4.2 | 8.5 | 117.7 | 80-100 | 45-60 | 80-90 | 3-10 | 18.5x4 |

Ƙirƙira da Gudanarwa

Samfurin Ƙarshe

Ziyarar Abokin Ciniki

Bayarwa

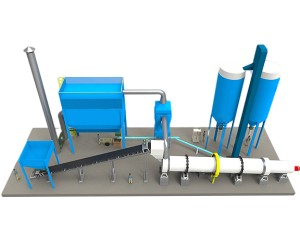

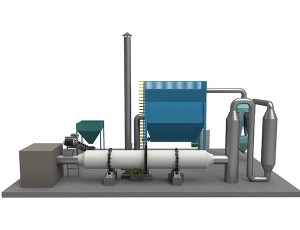

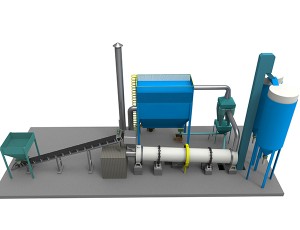

Hotunan Rukunan Aiki