VSPF Stacked Lim Xovxwm

VSPF Stacked Lim Xovxwm

Khoom nta

siv cov txheej txheem stacked rau daim hlau, siv cov cuab yeej pab qhia kev ua haujlwm kom ruaj khov.

● Kev sib xyaw lim, extrusion, ntxuav, cua qhuav, ncuav mog qab zib tawm thiab ntxuav ntaub ua ke.

● Lub extrusion siab txog li 1.6MPa, nws dav siv nyob rau hauv lub teb uas muaj ntau yam kev cai rau ncuav mog qab zib noo noo.

● 4.siv hydraulic tsav tswj qhov system, ua rau kev ua haujlwm ruaj khov thiab nrog kev siv hluav taws xob tsawg.

● Integrate PLC, HMI thiab cov cuab yeej tswj qhov system thiab lwm yam ntse ua ke, nws ua rau cov lim dej ntau dua thiab yooj yim dua.

● Siv lub tshuab ntxuav dej siab kom ua kom cov ntaub ntxhua zoo dua.

● Tsim nrog lub voj voog chamber, cov qauv tsim nyog, qhov ua tau zoo dua qub.

Txoj Cai Kev Ua Haujlwm

1 、 Kev lim dej: Thaum cov phiajcim kaw, tso cov slurry rau lim, siv cov xaim xaim rau cov khoom noj slurry rau txhua lub slurry chamber, thiab lim dhau los ntawm daim ntaub los lim cov thav duab thiab tawm tawm, cov khoom tsim lub ncuav mog qab zib ntawm daim ntaub nto.

2 、 Extrusion : Cov dej siab siab pub rau hauv lub chamber ntawm roj hmab diaphragm, ua kom lub diaphragm nthuav dav thiab extruding lub ncuav mog qab zib thiab cov kua yuav extruding tawm ntawm ncuav mog qab zib.

3 、 Kev ntxuav ncuav mog qab zib : ntxuav cov dej pub rau hauv slurry chamber los ntawm kev faib cov hose npog ntawm lub ncuav mog qab zib kom tiav, nyob rau hauv lub siab, cov dej ntxuav tau dhau los ntawm lub ncuav mog qab zib thiab daim ntaub kom tawm tawm.

4 、 Cua ziab: compressed cua los ntawm kev faib hose pub rau hauv slurry chamber thiab nias roj hmab diaphragm, ua rau cov dej siab hauv cov roj hmab diaphragm kom tawm tawm, thiab cov cua compressed dhau los ntawm lub ncuav mog qab zib thiab coj cov kua tawm los txo cov ncuav mog qab zib kom ntub dej. qib qis tshaj.

5 、 Lub ncuav mog qab zib tshem tawm: thaum ua tiav cov txheej txheem cua qhuav, qhib cov phiajcim, lub kaw lus tsav ua rau daim ntaub khiav thiab lub ncuav mog qab zib tawm ntawm ob sab ntawm lim tib lub sijhawm.

Nco tseg: Thov raws li qhov siv tiag tiag los kho lub sijhawm ntawm extrusion thiab cua tshuab ziab khaub ncaws.

Txheej Txheem Flow Diagram

Khoom Series

Technical Specification

| Qauv /VSPF yog ib qho ntawm cov khoom siv hluav taws xob zoo tshaj plaws | VSPF Ⅰ-1 | VSPF Ⅰ-2 | VSPF Ⅰ-3 |

| Lim cheeb tsam / m2 | 1 | 2 | 3 |

| Phaj loj / mm | 0,5m ua2/ txheej | ||

| Phaj qty/layer | 2 | 4 | 6 |

| Ntev / m | 2.5 | ||

| Dav / m | 1.5 | ||

| Qhov siab / m | 2 | 2.2 | 2.5 |

| Qhov hnyav / T | 8 | 9 | 10 |

| Hydraulic chaw nres tsheb fais fab / KW | 7.5 | ||

| Extrusion twj taub hau / m | 167 | ||

| Extrusion twj tso kua mis flowrate m3/h | 8 | ||

| Extrusion twj tso kua mis zog / KW | 7.5 | ||

Cov ntaub ntawv pab khoom siv

| Cov kav dej ntxhua khaub ncaws taub hau / m | 70 | ||

| Cov kav dej ntxhua khaub ncaws flowrate m3 / h | 10 | ||

| Ntaub ntxhua khaub ncaws taub hau / m | 70 | ||

| Ntaub ntxhua khaub ncaws flowrate m3/h | 10 | ||

| Slurry pub lub taub hau / m | 70 | ||

| Slurry pub twj tso kua mis flowrate m3 / h | Raws li cov ntaub ntawv slurry xaiv | ||

| Cua ziab siab / Mpa | 0.8 ua | ||

| Cua compressor flowrate rau cua kom qhuav m3 / min | 0.5 | 1 | 1.5 |

| Cua ziab tank ntim / m3 | 1 | 2 | 3 |

| Cua siab rau ntsuas / Mpa | 0.7 | ||

| Cua compressor flowrate rau ntsuas m3 / min | 0.3 | ||

| Instruments cua tank ntim / m3 | 0.5 | ||

| Lus Cim: Cov khoom siv qhia qhov loj me yog qhov loj me, tab sis tsis yog cov ntsiab lus loj, yog li qhov loj me no tsuas yog siv rau kev siv.Cov khoom sib txawv ntawm cov phaj, lub lim yuav muaj qhov sib txawv qhov siab thiab qhov hnyav.Cov ntaub ntawv pab khoom siv tsuas yog siv rau kev siv, nws yuav hloov pauv los ntawm kev ua haujlwm lim dej hauv cov slurry sib txawv. | |||

Technical Specification

| Qauv | VSPFⅡ-3 | VSPFⅡ-6 | VSPFⅡ-9 | VSPFⅡ-12 | VSPFⅡ-15 | VSPFⅡ-18 | VSPFⅡ-21 | VSPFⅡ-24 |

| lim cheeb tsam / m2 | 3 | 6 | 9 | 12 | 15 | 18 | 21 | 24 |

| phaj loj / hli | 1.5 m2 / txheej | |||||||

| phaj Qty / txheej | 2 | 4 | 6 | 8 | 10 | 12 | 14 | 16 |

| ntev / m | 3.7 | |||||||

| dav / m | 4.1 | |||||||

| qhov siab / m | 2.6 | 2.8 | 3.2 | 3.7 | 4.2 | 4.6 | 5.1 | 5.5 |

| hnyav / T | 12 | 13 | 14 | 15 | 16 | 17 | 18 | 19 |

| hydraulic chaw nres tsheb fais fab / KW | 11 | |||||||

| Extrusion twj taub hau / m | 28 | |||||||

| Extrusion twj tso kua mis flowrate m3 / h | 136 Lus Cim: yog extrusion siab tshaj 1.3MPa, cov ntaub ntawv no yog 164 | |||||||

| Extrusion twj tso kua mis zog / KW | 11 Ceeb toom: yog extrusion siab tshaj 1.3MPa, cov ntaub ntawv no yog 15 | |||||||

Cov ntaub ntawv pab khoom siv

| Tube ntxhua khaub ncaws taub hau / m | 68 | |||||||

| Cov kav dej ntxhua khaub ncaws flowrate m3/h | 20 | |||||||

| Ntaub ntxhua khaub ncaws taub hau / m | 70 | |||||||

| Ntaub ntxhua khaub ncaws flowrate m3/h | 12 | |||||||

| Slurry pub lub taub hau / m | 70 | |||||||

| Slurry pub twj tso kua mis flowrate m3/h | Raws li cov ntaub ntawv slurry xaiv | |||||||

| Cua ziab siab / Mpa | 0.8 ua | |||||||

| Cua compressor flowrate rau cua kom qhuav m3/ min | Raws li cov ntaub ntawv slurry xaiv | |||||||

| Cua ziab tank ntim / m3 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 |

| Cua siab rau ntsuas / Mpa | 0.7 | |||||||

| Cua compressor flowrate rau ntsuas m3/ min | 0.5 | |||||||

| Instruments cua tank ntim / m3 | 1 | |||||||

| Lus Cim: Cov khoom siv qhia qhov loj me yog qhov loj me, tab sis tsis yog cov ntsiab lus loj, yog li qhov loj me no tsuas yog siv rau kev siv.Cov khoom sib txawv ntawm cov phaj, lub lim yuav muaj qhov sib txawv qhov siab thiab qhov hnyav.Cov ntaub ntawv pab khoom siv tsuas yog siv rau kev siv, nws yuav hloov pauv los ntawm kev ua haujlwm lim dej hauv cov slurry sib txawv. | ||||||||

Technical Specification

| Qauv VSPF Ⅲ | VSPFⅢ-18 | VSPFⅢ-24 | VSPFⅢ-30 | VSPFⅢ-36 | VSPFⅢ-42 | VSPFⅢ-48 | VSPFⅢ-54 | VSPFⅢ-60 | VSPFⅢ-66 |

| lim cheeb tsam / m2 | 18 | 24 | 30 | 36 | 42 | 48 | 54 | 60 | 66 |

| phaj loj / hli | 3.0m2 / txheej | ||||||||

| phaj Qty / txheej | 6 | 8 | 10 | 12 | 14 | 16 | 18 | 20 | 22 |

| ntev / m | 5.1 | ||||||||

| dav / m | 5.5 | ||||||||

| qhov siab / m | 4.3 | 4.5 | 4.9 | 5.4 | 5.8 | 6.3 | 6.8 | 7.2 | 7.7 |

| hnyav / T | 31 | 33 | 35 | 37 | 39 | 41 | 43 | 45 | 47 |

| hydraulic chaw nres tsheb powerKW | 22 | ||||||||

| Extrusion twj taub hau / m | 40 | 55 | |||||||

| Extrusion twj tso kua mis flowrate m3 / h | 136 Lus Cim: yog extrusion siab tshaj 1.3MPa, cov ntaub ntawv no yog 162 | 135 Ceeb toom: yog extrusion siab tshaj 1.3MPa, cov ntaub ntawv no yog 166 | |||||||

| Extrusion twj tso kua mis zog / KW | 15 Lus Cim: yog extrusion siab tshaj 1.3MPa, cov ntaub ntawv no yog 18.5 | 22 Ceeb toom: yog extrusion siab tshaj 1.3MPa, cov ntaub ntawv no yog 30 | |||||||

Cov ntaub ntawv pab khoom siv

| Cov kav dej ntxhua khaub ncaws taub hau / m | 65 | ||||||||

| Cov kav dej ntxhua khaub ncaws flowrate m3 / h | 26 | ||||||||

| Ntaub ntxhua khaub ncaws taub hau / m | 70 | ||||||||

| Ntaub ntxhua khaub ncaws flowrate m3/h | 16 | ||||||||

| Slurry pub lub taub hau / m | 70 | ||||||||

| Slurry pub twj tso kua mis flowrate m3 / h | Raws li cov ntaub ntawv slurry xaiv | ||||||||

| Cua ziab siab / Mpa | 0.8 ua | ||||||||

| Cua compressor flowrate rau cua kom qhuav m3 / min | Raws li cov ntaub ntawv slurry xaiv | ||||||||

| Cua ziab tank ntim / m3 | 8 | 10 | 10 | 12 | 12 | 15 | 15 | 20 | 20 |

| Cua siab rau ntsuas / Mpa | 0.7 | ||||||||

| Cua compressor flowrate rau ntsuas m3 / min | 0.5 | ||||||||

| Instruments cua tank ntim / m3 | 1 | ||||||||

| Lus Cim: Cov khoom siv qhia qhov loj me yog qhov loj me, tab sis tsis yog cov ntsiab lus loj, yog li qhov loj me no tsuas yog siv rau kev siv.Cov khoom sib txawv ntawm cov phaj, lub lim yuav muaj qhov sib txawv qhov siab thiab qhov hnyav.Cov ntaub ntawv pab khoom siv tsuas yog siv rau kev siv, nws yuav hloov pauv los ntawm kev ua haujlwm lim dej hauv cov slurry sib txawv. | |||||||||

Technical Specification

| Qauv VSPF yog ib qho yooj yim rau nruab | VSPFⅣ-60 | VSPFⅣ-72 | VSPFⅣ-84 | VSPFⅣ-96 | VSPFⅣ-108 | VSPFⅣ-120 | VSPFⅣ-132 | VSPFⅣ-144 | VSPFⅣ-156 | VSPFⅣ-168 |

| Lim cheeb tsam / m2 | 60 | 72 | 84 | 96 | 108 | 120 | 132 | 144 | 156 | 168 |

| Phaj loj / mm | 6m2 / txheej | |||||||||

| Phaj Qty / txheej | 10 | 12 | 14 | 16 | 18 | 20 | 22 | 24 | 26 | 28 |

| Ntev / m | 7.1 | |||||||||

| Dav / m | 5.5 | |||||||||

| Qhov siab / m | 5.4 | 5.8 | 6.2 | 6.6 | 6.9 | 7.2 | 7.6 | 7.9 ib | 8.3 | 8.6 |

| Qhov hnyav / T | 92 | 96 | 100 | 104 | 108 | 112 | 116 | 120 | 124 | 128 |

| Hydraulic chaw nres tsheb fais fab / KW | 30 | 37 | ||||||||

| Extrusion twj taub hau / m | 110 | 150 | ||||||||

| Extrusion twj tso kua mis flowrate m3 / h | 126 Ceeb toom: yog extrusion siab tshaj 1.3MPa, cov ntaub ntawv no yog 168 | 128 Ceeb toom: yog extrusion siab tshaj 1.3MPa, cov ntaub ntawv no yog 162.5 | ||||||||

| Extrusion twj tso kua mis zog / KW | 37 Ceeb toom: yog extrusion siab tshaj 1.3MPa, cov ntaub ntawv no yog 45 | 55 Nco tseg:> 1.3MPa, cov ntaub ntawv no yog 75 | ||||||||

Cov ntaub ntawv pab khoom siv

| Cov kav dej ntxhua khaub ncaws taub hau / m | 72 | |||||||||

| Cov kav dej ntxhua khaub ncaws flowrate m3/h | 36 | |||||||||

| Ntaub ntxhua khaub ncaws taub hau / m | 70 | |||||||||

| Ntaub ntxhua khaub ncaws flowrate m3/h | 20 | |||||||||

| Slurry pub lub taub hau / m | 70 | |||||||||

| Slurry pub twj tso kua mis flowrate m3/h | Raws li cov ntaub ntawv slurry xaiv | |||||||||

| Cua ziab siab / Mpa | 0.8 ua | |||||||||

| Cua compressor flowrate rau cua kom qhuav m3/ min | Raws li cov ntaub ntawv slurry xaiv | |||||||||

| Cua ziab tank ntim / m3 | 20 | 20 | 25 | 30 | 35 | 35 | 40 | 40 | 45 | 45 |

| Cua siab rau ntsuas / Mpa | 0.7 | |||||||||

| Cua compressor flowrate rau ntsuas m3/ min | 1 | |||||||||

| Instruments cua tank ntim / m3 | 2 | |||||||||

| Lus Cim: Cov khoom siv qhia qhov loj me yog qhov loj me, tab sis tsis yog cov ntsiab lus loj, yog li qhov loj me no tsuas yog siv rau kev siv.Cov khoom sib txawv ntawm cov phaj, lub lim yuav muaj qhov sib txawv qhov siab thiab qhov hnyav.Cov ntaub ntawv pab khoom siv tsuas yog siv rau kev siv, nws yuav hloov pauv los ntawm kev ua haujlwm lim dej hauv cov slurry sib txawv. | ||||||||||

Daim ntawv thov teb

Nws yog dav siv hauv cov kav dej hauv nroog, textile printing thiab dyeing, electroplate, papermaking, tawv, brewing, zaub mov ua, thee ntxuav, petrochemical kev lag luam, chemistry, metallurgy, ntxhia sib cais, chaw muag tshuaj, ceramic kev lag luam sludge dewatering thiab hais txog, kuj siv nyob rau hauv kev lag luam ntau lawm khoom-kua sib cais los yog kua leaching txheej txheem.

| Tsis muaj. | Khoom npe | Pub solidity (g / l) | Extrusion dej ressure (MPa) | ncuav mog qab zib thickness (mm) | ncuav mog qab zib noo noo (%) | Muaj peev xwm kg/m2.h |

| 1 | 4A-zeolite | 150-295 : kuv | 1.4 | 35 | 19-22 : kuv | 190-200 Nws |

| 2 | Sulfuret | ≈50 | 1.2 | 30 | 30 | 120 |

| 3 | Coj | ≈50 | 1.2 | 30 | 15 ~ 20 | 35 |

| 4 | tooj liab slag | 600 | 1.6 | 40 | 8 ~ 9 | 310 |

| 5 | Cov dej khib nyiab sulphate | 80 | 1.6 | 45 | 28-35 : kuv | 120-175 : kuv |

| 6 | Calcination kub tailings | 300 | 1.6 | 35 | 14-18 : kuv | 300-340 Nws |

| 7 | Superfine aluminium hydroxide | 15 ~ 20% | 1.6 | 20 | 29.5-32.5 Nws | 65 |

| 8 | Cu-Ni concentration | 66.7 ib | 1.6 | 30 | 9.78 ib | 257 |

| 9 | Copper concentration | 45-50 : kuv | 1.6 | 35 | 7.6 | 360 |

| 10 | Nws concentration | 45-50 : kuv | 1.6 | 30 | 8 | 300-400 |

| 11 | Tantalum-niobium smelt | 1.6 | 20 ~ 25 | 200 | ||

| 12 | Coal slime | 30 ~ 35% | 1.6 | 30 | 16-17 : kuv | 300 |

| 14 | Kub tailings tom qab flotation | 20 ~ 30% | 1.6 | 35 | 12-18 : kuv | 300 |

| 15 | Mannitol | 1.5 | 12 | 35 | ||

| 16 | Zinc oxide hmoov | 57% | 1.6 | 18 | 20 | 90 |

| 17 | Leaching residue ntawm zinc oxide | 50% | 1.6 | 10 | 18-20 : kuv | 70 |

| 18 | Sulfur concentrate | 10% | 1.6 | 20 | 25-35 : kuv | 200 |

Cov khoom siv

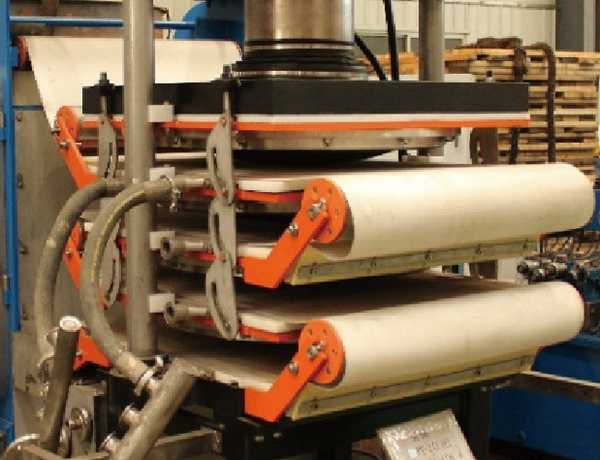

Plate Group Structure

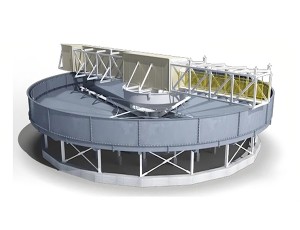

Tsim cov duab

Qhov tseem ceeb

Siv Site