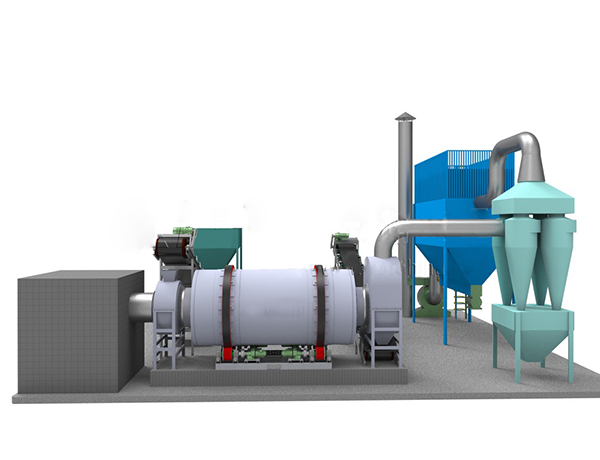

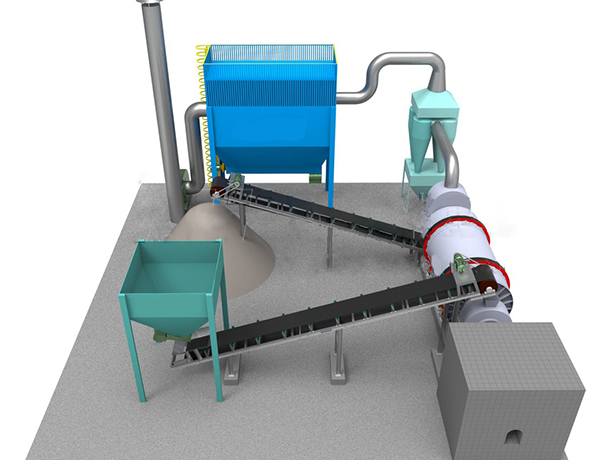

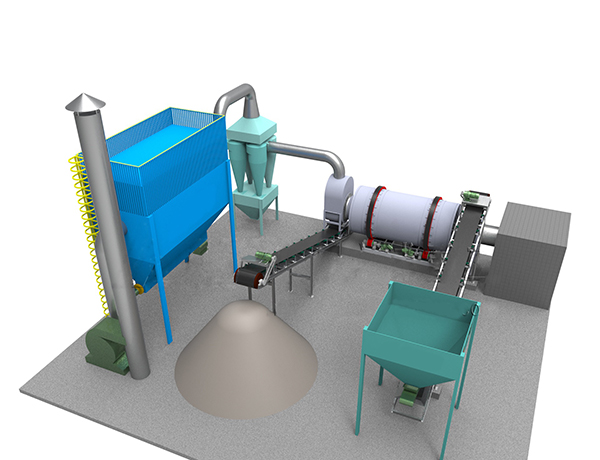

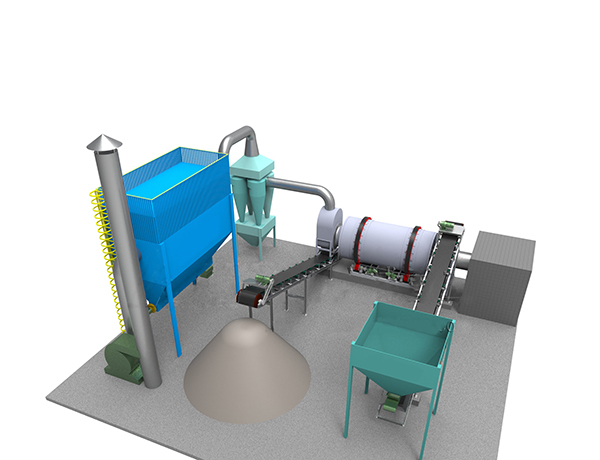

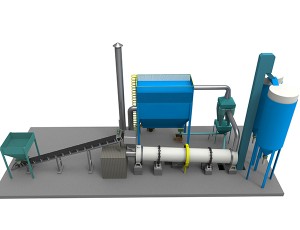

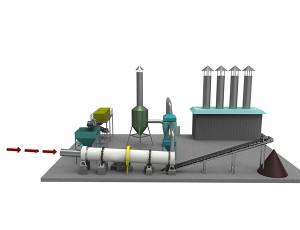

Sistem Pengeringan Bahan Granular

Sistem Pengeringan Bahan Granular

Kaluwihan Sistem

Efisiensi termal sing dhuwur

Bahan pengawetan panas kanthi resistensi panas sing dhuwur, digabungake karo fitur panggunaan panas pengering telung silinder, efek hemat energi jelas.

Investasi peralatan kurang

Suhu materi <50 ℃, sing bisa langsung dilebokake ing gudang materi, lan piranti pendinginan ora dibutuhake;suhu gas buntut kurang, peralatan mbusak bledug karo umur layanan maneh.

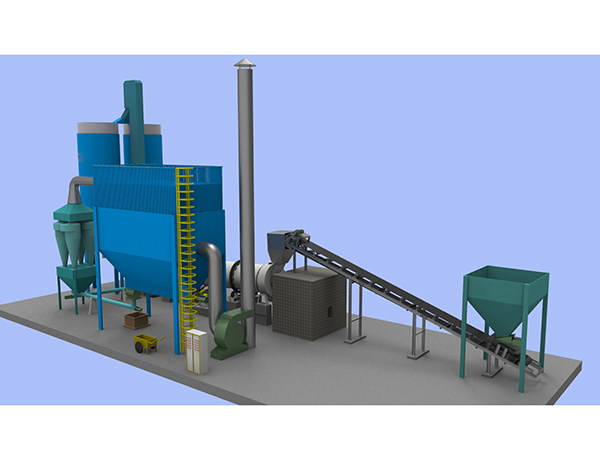

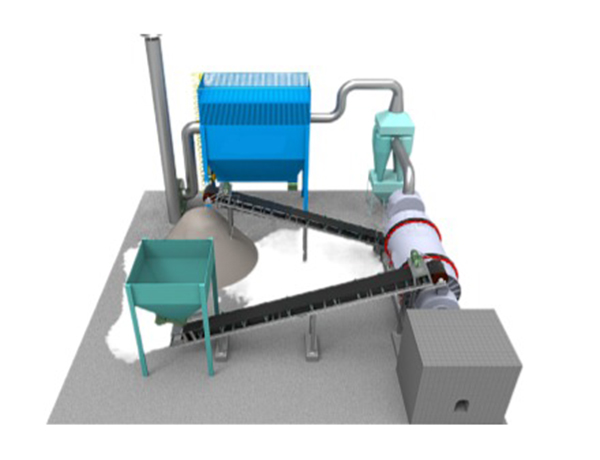

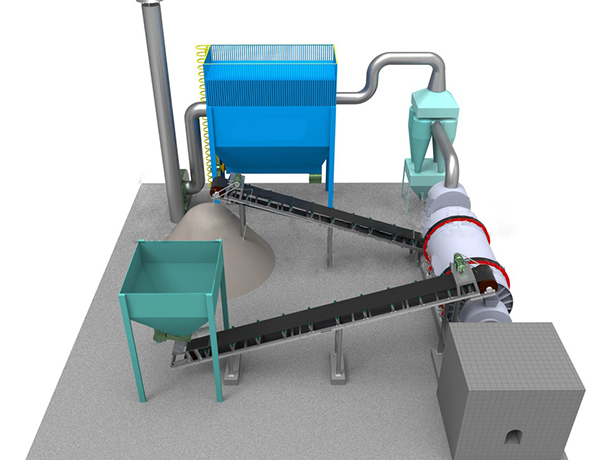

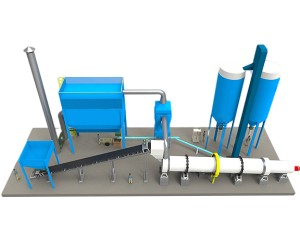

Papan lemah cilik, gampang dipasang

Wilayah sing ditutupi 50% kurang saka pengering silinder tunggal, investasi konstruksi dikurangi 50% lan konsumsi listrik dikurangi 60%, tata letak sistem pangatusan kompak kanthi aliran proses sing gampang.

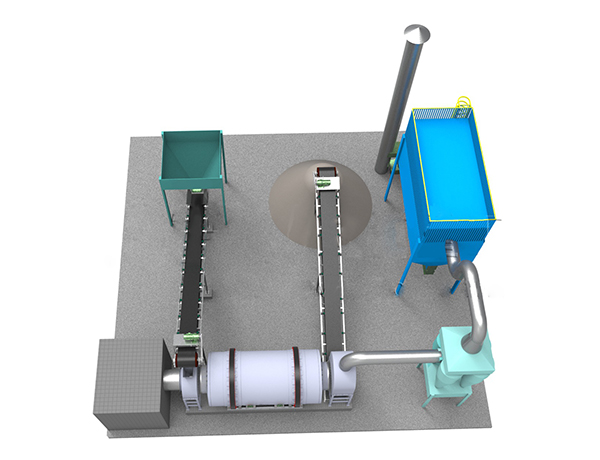

Prinsip Kerja

Bahan kasebut dilebokake ing kiln sanajan mburi kiln (sisih ndhuwur silinder).Amarga silinder kepekso lan muter alon-alon, materi obah bebarengan karo bunder lan arah aksial (saka sisih ndhuwur menyang sisih ngisor).Sawise ngalami owah-owahan fisik lan kimia, materi kasebut mlebu ing mesin pendingin liwat tutup sirah kiln sawise kalsinasi rampung.Bahan bakar diwenehake menyang sirah kiln liwat sirah kiln, lan gas buang bakal dibuwang ing mburi kiln sawise ngganti panas karo materi.

Parameter Teknis Pengering Tiga Silinder

| Model | Data silinder | Kapasitas (t/h) | kacepetan rotary silinder (r/min) | daya (kW) | ||||

| diameteripun silinder njaba (m) | Dawane silinder njaba (m) | Volume silinder (m3) | kali wedhi | Awu mabur | Slag | |||

| VS6203 | 1.6 | 1.8 | 3.6 | 2-3 | 1-2 | 1-2 | 3-10 | 4 |

| VS6205 | 2 | 2 | 6.28 | 4-5 | 2-3 | 3-4 | 3-10 | 5.5 |

| VS6210 | 2.2 | 2.5 | 9.5 | 8-10 | 4-5 | 6-8 | 3-10 | 7.5 |

| VS6215 | 2.5 | 2.8 | 13.7 | 12-15 | 7-8 | 10-12 | 3-10 | 11 |

| VS2 × 4 | 2 | 4 | 12.56 | 8-12 | 4-6 | 8-10 | 3-10 | 3×2 |

| VS2 × 5 | 2 | 5 | 15.7 | 12-15 | 6-7 | 10-13 | 3-10 | 4×2 |

| VS2 × 6 | 2 | 6 | 18.84 | 20-25 | 10-17 | 20-27 | 3-10 | 7.5×2 |

| VS2.2×4.5 | 2.2 | 4.5 | 17.09 | 14-18 | 7-9 | 12-15 | 3-10 | 5.5×2 |

| VS2.5×6 | 2.5 | 6.5 | 31.89 | 23-28 | 10-13 | 20-22 | 3-10 | 5.5×4 |

| VS2.7×7 | 2.7 | 7 | 40.5 | 30-35 | 20-25 | 27-45 | 3-10 | 7.5×4 |

| VS2.8×6 | 2.8 | 6 | 36.9 | 30-35 | 15-18 | 25-30 | 3-10 | 5.5×4 |

| VS3×6 | 3 | 6 | 42.39 | 35-40 | 18-20 | 32-35 | 3-10 | 7.5×4 |

| VS3×7 | 3 | 7 | 49.46 | 40-45 | 20-25 | 35-40 | 3-10 | 7.5×4 |

| VS3.2×7 | 3.2 | 7 | 56.26 | 45-50 | 25-30 | 40-45 | 3-10 | 11×4 |

| VS3.2×8 | 3.2 | 8 | 64.3 | 50-55 | 30-35 | 45-50 | 3-10 | 11×4 |

| VS3.6×8 | 3.6 | 8 | 81.38 | 60-70 | 35-40 | 60-65 | 3-10 | 15×4 |

| VS3.8×9 | 3.8 | 9 | 102 | 70-80 | 40-45 | 70-75 | 3-10 | 15×4 |

| VS4 × 10 | 4 | 10 | 125.6 | 90-100 | 45-50 | 80-90 | 3-10 | 18.5×4 |

| VS4.2×8.5 | 4.2 | 8.5 | 117.7 | 80-100 | 45-60 | 80-90 | 3-10 | 18.5×4 |

Produk Kering