Rotary Kiln kanggo Pabrik Produksi Semen

Rotary Kiln kanggo Pabrik Produksi Semen

Pambuka

Cement Kiln utamané digunakake kanggo calcinating klinker lan wis jinis garing lan jinis udan.

Kiln Metullurgical lan kimia utamané digunakake kanggo kalsinasi magnetisasi bijih wesi miskin, kalsinasi oksidasi bijih kromium, bijih feronikel;kalsinasi bijih bauksit aluminium dhuwur ing pabrik bahan refraktori lan aluminium hidroksida, klinker, kalsinasi aluminium hidroksida ing pabrik aluminium;kalsinasi bijih krom lan bubuk krom ing pabrik kimia, lsp.

Kiln kapur aktif digunakake kanggo kalsinasi kapur aktif lan dolomit ing pabrik baja lan pabrik wesi.

Prinsip Kerja

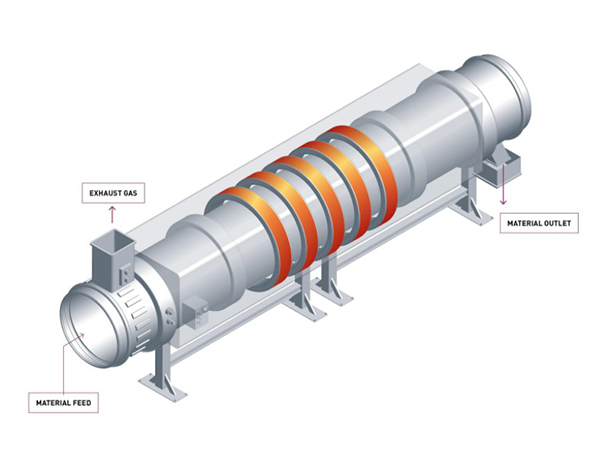

Bahan kasebut dilebokake ing kiln sanajan mburi kiln (sisih ndhuwur silinder).Amarga silinder kepekso lan muter alon-alon, materi obah bebarengan karo bunder lan arah aksial (saka sisih ndhuwur menyang sisih ngisor).Sawise ngalami owah-owahan fisik lan kimia, materi kasebut mlebu ing mesin pendingin liwat tutup sirah kiln sawise kalsinasi rampung.Bahan bakar diwenehake menyang sirah kiln liwat sirah kiln, lan gas buang bakal dibuwang ing mburi kiln sawise ngganti panas karo materi.

Parameter teknis

| Model | Parameter kiln | Kapasitas (t/d) | Kacepetan Rotary (r/min) | Daya (kW) | Bobot (t) | ||

| Dhiameter (m) | Dawane (m) | Lereng (%) | |||||

| VS1.4x33 | 1.4 | 33 | 3 | 26 | 0.39-3.96 | 18.5 | 48 |

| VS1.6x36 | 1.6 | 36 | 4 | 37 | 0.26-2.63 | 22 | 52 |

| VS1.8x45 | 1.8 | 45 | 4 | 52 | 0.16-1.62 | 30 | 78 |

| VS1.9x39 | 1.9 | 39 | 4 | 56 | 0.29-2.93 | 30 | 78 |

| VS2.0x40 | 2 | 40 | 3 | 78 | 0.23-2.26 | 37 | 119 |

| VS2.2x45 | 2.2 | 45 | 3.5 | 106 | 0.21-2.44 | 45 | 128 |

| VS2.5x40 | 2.5 | 40 | 3.5 | 180 | 0.44-2.44 | 55 | 150 |

| VS2.5x50 | 2.5 | 50 | 3 | 200 | 0.62-1.86 | 55 | 187 |

| VS2.5x54 | 2.5 | 54 | 3.5 | 204 | 0.48-1.45 | 55 | 196 |

| VS2.7x42 | 2.7 | 42 | 3.5 | 320 | 0.10-1.52 | 55 | 199 |

| VS2.8x44 | 2.8 | 44 | 3.5 | 400 | 0.437-2.18 | 55 | 202 |

| VS3.0x45 | 3 | 45 | 3.5 | 500 | 0.5-2.47 | 75 | 211 |

| VS3.0x48 | 3 | 48 | 3.5 | 700 | 0.6-3.48 | 100 | 237 |

| VS3.0x60 | 3 | 60 | 3.5 | 300 | 0.3-2 | 100 | 310 |

| VS3.2x50 | 3.2 | 50 | 4 | 1000 | 0.6-3 | 125 | 278 |

| VS3.3x52 | 3.3 | 52 | 3.5 | 1300 | 0.266-2.66 | 125 | 283 |

| VS3.5x54 | 3.5 | 54 | 3.5 | 1500 | 0.55-3.4 | 220 | 363 |

| VS3.6x70 | 3.6 | 70 | 3.5 | 1800 | 0.25-1.25 | 125 | 419 |

| VS4.0x56 | 4 | 56 | 4 | 2300 | 0.41-4.07 | 315 | 456 |

| VS4.0x60 | 4 | 60 | 3.5 | 2500 | 0.396-3.96 | 315 | 510 |

| VS4.2x60 | 4.2 | 60 | 4 | 2750 | 0.4-3.98 | 375 | 633 |

| VS4.3x60 | 4.3 | 60 | 3.5 | 3200 | 0.396-3.96 | 375 | 583 |

| VS4.5x66 | 4.5 | 66 | 3.5 | 4000 | 0.41-4.1 | 560 | 710 |

| VS4.7x74 | 4.7 | 74 | 4 | 4500 | 0.35-4 | 630 | 849 |

| VS4.8x74 | 4.8 | 74 | 4 | 5000 | 0.396-3.96 | 630 | 899 |