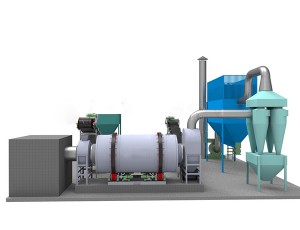

Telung Silinder utawa Drum Dryer

Telung Silinder utawa Drum Dryer

Karakteristik kinerja

1. Suhu udhara stopkontak kurang, umur layanan luwih saka peralatan bledug.

2. Ukuran bahan bongkahan, partikel, lan bubuk kurang saka 20mm bisa dikeringake.

3. Gear driving ora dibutuhake lan iku langsung mimpin dening roller, karo efficiency mechanical luwih.

4. Tanpa kedadean bocor online, kangelan sealing babar blas ditanggulangi, lan instalasi bisa rampung ing sawetara jam.

5. 50% saka area isine wis suda dibandhingake karo dryer drum siji, lan investasi tanah suda dening 50%, konsumsi daya suda dening 60%.

6. Efisiensi termal insulasi saka pengering telung silinder bisa tekan ndhuwur 70% (efisiensi termal insulasi saka pengering drum tunggal tradisional mung 35%), duwe efek hemat energi sing luar biasa.

7. Indikator kelembapan pungkasan bisa diatur kanthi gampang miturut panyuwunan.

8. Kurang saka 1% saka Kelembapan materi bisa njamin dening telung silinder dryer, kang produk preferred kanggo mortir campuran garing lan baris produksi wêdakakêna slag.

9. Suhu bahan sing dibuwang yaiku <50 ℃, sing bisa langsung dikirim menyang silo panyimpenan, ora perlu adhem ing gudang pendinginan.

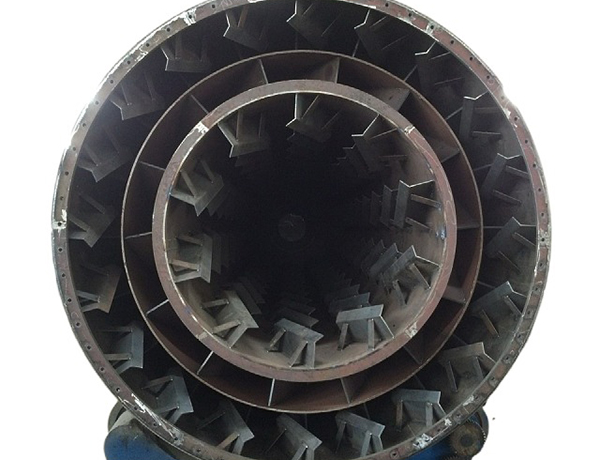

Prinsip Kerja

Bahan njaluk menyang drum Rotary internal saka piranti dipakani, kanggo éling pangatusan hilir, bahan sing diangkat munggah lan mudhun terus-terusan dening lapisan utama ngangkat piring lan exchange panas temen maujud ing wangun spiral obah, bahan pindhah menyang sisih liyane. saka silinder utama lan banjur njaluk menyang silinder tengah, lan bahan sing diangkat munggah lan dipindhah maju ing silinder tengah, dening cara loro langkah maju lan siji langkah maneh, bahan nyerep panas loro teka saka silinder utama lan tengah. silinder, Kangge, wektu pangatusan punika dipun danguaken, lan bahan tekan status pangatusan paling luweh ing tataran iki.Material mindhah mburi liyane saka silinder tengah lan banjur njaluk menyang silinder njaba, bahan pepe sing cepet dibuwang saka silinder ing fungsi angin panas.

Parameter teknis

| Model | Data silinder | Kapasitas (t/h) | kacepetan rotary silinder (r/min) | daya (kW) | ||||

| diameteripun silinder njaba (m) | Dawane silinder njaba (m) | Volume silinder (m3) | kali wedhi | Awu mabur | Slag | |||

| VS6203 | 1.6 | 1.8 | 3.6 | 2-3 | 1-2 | 1-2 | 3-10 | 4 |

| VS6205 | 2 | 2 | 6.28 | 4-5 | 2-3 | 3-4 | 3-10 | 5.5 |

| VS6210 | 2.2 | 2.5 | 9.5 | 8-10 | 4-5 | 6-8 | 3-10 | 7.5 |

| VS6215 | 2.5 | 2.8 | 13.7 | 12-15 | 7-8 | 10-12 | 3-10 | 11 |

| VS2x4 | 2 | 4 | 12.56 | 8-12 | 4-6 | 8-10 | 3-10 | 3x2 |

| VS2x5 | 2 | 5 | 15.7 | 12-15 | 6-7 | 10-13 | 3-10 | 4x2 |

| VS2x6 | 2 | 6 | 18.84 | 20-25 | 10-17 | 20-27 | 3-10 | 7,5x2 |

| VS2.2x4.5 | 2.2 | 4.5 | 17.09 | 14-18 | 7-9 | 12-15 | 3-10 | 5,5x2 |

| VS2.5x6 | 2.5 | 6.5 | 31.89 | 23-28 | 10-13 | 20-22 | 3-10 | 5,5x4 |

| VS2.7x7 | 2.7 | 7 | 40.5 | 30-35 | 20-25 | 27-45 | 3-10 | 7,5x4 |

| VS2.8x6 | 2.8 | 6 | 36.9 | 30-35 | 15-18 | 25-30 | 3-10 | 5,5x4 |

| VS3x6 | 3 | 6 | 42.39 | 35-40 | 18-20 | 32-35 | 3-10 | 7,5x4 |

| VS3x7 | 3 | 7 | 49.46 | 40-45 | 20-25 | 35-40 | 3-10 | 7,5x4 |

| VS3.2x7 | 3.2 | 7 | 56.26 | 45-50 | 25-30 | 40-45 | 3-10 | 11x4 |

| VS3.2x8 | 3.2 | 8 | 64.3 | 50-55 | 30-35 | 45-50 | 3-10 | 11x4 |

| VS3.6x8 | 3.6 | 8 | 81.38 | 60-70 | 35-40 | 60-65 | 3-10 | 15x4 |

| VS3.8x9 | 3.8 | 9 | 102 | 70-80 | 40-45 | 70-75 | 3-10 | 15x4 |

| VS4x10 | 4 | 10 | 125.6 | 90-100 | 45-50 | 80-90 | 3-10 | 18,5x4 |

| VS4.2x8.5 | 4.2 | 8.5 | 117.7 | 80-100 | 45-60 | 80-90 | 3-10 | 18,5x4 |

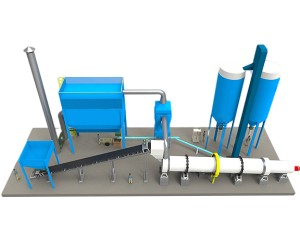

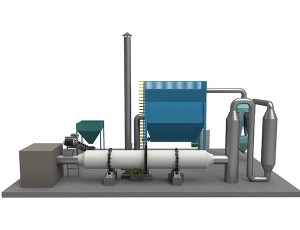

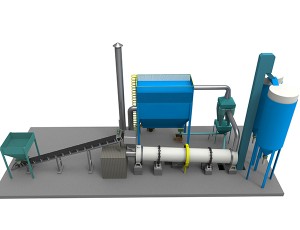

Produksi lan Pangolahan

Produk Rampung

Kunjungan Pelanggan

Pangiriman

Foto Situs Kerja