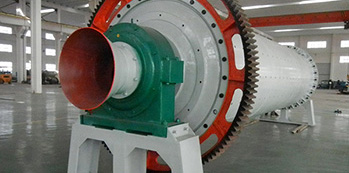

A ball mill is a type of grinder used to grind or blend materials for use in mineral dressing processes, paints, pyrotechnics, ceramics, and selective laser sintering. It works on the principle of impact and attrition: size reduction is done by impact as the balls drop from near the top of the shell.

According to its application, the ball mill can be divided into wet type ball and dry type ball mill, intermittent ball mill, rod mill, cement ball mill, ceramic ball mill, fly ash ball mill, aluminum ash ball mill, overflow ball mill, grate discharge ball mill gold mill, steel slag ball mill, etc.

A ball mill consists of a hollow cylindrical shell rotating about its axis. The axis of the shell may be either horizontal or at a small angle to the horizontal. It is partially filled with balls. The grinding media are the balls, which may be made of steel (chrome steel), stainless steel, ceramic, or rubber. The inner surface of the cylindrical shell is usually lined with an abrasion-resistant material such as manganese steel or rubber lining. Less wear takes place in rubber lined mills. The length of the mill is approximately equal to its diameter.

Working

In case of continuously operated ball mill, the material to be ground is fed from the left through a 60° cone and the product is discharged through a 30° cone to the right. As the shell rotates, the balls are lifted up on the rising side of the shell and then they cascade down (or drop down on to the feed), from near the top of the shell. In doing so, the solid particles in between the balls and ground are reduced in size by impact.

Applications

Ball mills are used for grinding materials such as coal, pigments, and feldspar for pottery. Grinding can be carried out wet or dry, but the former is performed at low speed. Blending of explosives is an example of an application for rubber balls. For systems with multiple components, ball milling has been shown to be effective in increasing solid-state chemical reactivity. Additionally, ball milling has been shown effective for production of amorphous materials.

Advantages Of The Ball Mill

Ball milling boasts several advantages over other systems: the cost of installation and grinding medium is low; the capacity and fineness can be adjusted by adjusting the diameter of the ball; it is suitable for both batch and continuous operation; it is suitable for open and closed-circuit grinding; it is applicable for materials of all degrees of hardness.

Post time: Jun-11-2022