VSPF Stacked Filter Press

VSPF Stacked Filter Press

Zida Zida

gwiritsani ntchito mawonekedwe okhazikika pama mbale, gwiritsani ntchito kalozera wothandizira kuti ntchitoyo ikhale yokhazikika.

● Phatikizani kusefa, kutulutsa, kuchapa, kuyanika mpweya, kutulutsa keke ndi kuchapa nsalu pamodzi.

● Kuthamanga kwa extrusion mpaka 1.6MPa, kumagwiritsidwa ntchito kwambiri m'munda umene uli ndi zofunikira zosiyana za chinyezi cha keke.

● 4.gwiritsani ntchito hydraulic drive control system, pangani ntchitoyo kukhala yokhazikika komanso yopanda mphamvu.

● Phatikizani PLC, HMI ndi zida zowongolera zida ndi zina zanzeru pamodzi, zimapangitsa fyuluta kukhala yabwino komanso yosavuta.

● Gwiritsani ntchito chipangizo choyeretsera madzi othamanga kwambiri kuti kuchapa nsalu kukhale kothandiza kwambiri.

● Kujambula ndi chipinda chozungulira, kamangidwe kake kamakhala koyenera, kachitidwe kake kamakhala koonekera kwambiri.

Mfundo Yoyendetsera Ntchito

1, Kusefa: pamene mbale gulu chatsekedwa, mpope slurry kuti fyuluta, ntchito anagawira payipi kudyetsa slurry ku chipinda chilichonse slurry, ndi kusefera kudutsa nsalu kusefera chimango ndi kutulutsa kunja, olimba anapanga keke pamwamba nsalu.

2, Extrusion: madzi kuthamanga kwambiri kudyetsedwa m'chipinda chapamwamba cha mphira diaphragm, kupanga diaphragm kukula ndi extruding keke ndi madzi adzakhala extruding kunja keke.

3, Kutsuka keke: kutsuka madzi kudya mu slurry chipinda kudzera anagawira payipi chivundikiro pa keke kwathunthu, pansi pa kupsyinjika, ndi kutsuka madzi kudutsa keke ndi nsalu kutulutsa kunja.

4, Air kuyanika: wothinikizidwa mpweya kudzera anagawira payipi kudya mu slurry chipinda ndi kukanikiza mphira diaphragm, kupanga mkulu-anzanu madzi mu mphira diaphragm kutulutsa kunja, ndi wothinikizidwa mpweya kudutsa keke ndi kutenga madzi kuti kuchepetsa keke chinyezi. mlingo wotsika kwambiri.

5, Kutulutsa keke: mukamaliza kuyanika mpweya, tsegulani mbale zamagulu, makina oyendetsa galimoto amapangitsa kuti nsaluyo ikhale yothamanga ndi keke imatuluka mbali ziwiri za fyuluta nthawi yomweyo.

Chidziwitso: Chonde molingana ndi momwe mungagwiritsire ntchito kusintha nthawi ya extrusion ndi air- dryness process.

Ndondomeko Yoyenda Chithunzi

Zida Series

Kufotokozera zaukadaulo

| Chitsanzo/VSPF Ⅰ | VSPFⅠ-1 | VSPFⅠ-2 | VSPFⅠ-3 |

| Malo osefera/m2 | 1 | 2 | 3 |

| Kukula kwa mbale / mm | 0.5m2/gawo | ||

| Plate qty/layer | 2 | 4 | 6 |

| Utali/m | 2.5 | ||

| M'lifupi/m | 1.5 | ||

| Kutalika/m | 2 | 2.2 | 2.5 |

| Kulemera/T | 8 | 9 | 10 |

| Mphamvu ya Hydraulic station/KW | 7.5 | ||

| Pampu yotulutsa mutu/m | 167 | ||

| Kutulutsa kwapampu yotulutsa m3/h | 8 | ||

| Mphamvu ya mpope yowonjezera/KW | 7.5 | ||

Data Yothandizira Zida

| Kuchapira mapampu mutu/m | 70 | ||

| mpope wochapira zitoliro umayenda m3/h | 10 | ||

| Pampu yochapira nsalu mutu/m | 70 | ||

| Pampu yochapira nsalu imayenda m3/h | 10 | ||

| Pampu yoledzera yothira mutu/m | 70 | ||

| Pampu yamadzi yotsekemera imatuluka m3/h | Malinga ndi slurry deta kusankha | ||

| Air drying pressure/Mpa | 0.8 | ||

| Mayendedwe a mpweya wa kompresa poyanika mpweya m3/min | 0.5 | 1 | 1.5 |

| Kuchuluka kwa thanki yowumitsa mpweya/m3 | 1 | 2 | 3 |

| Kuthamanga kwa mpweya kwa zida/Mpa | 0.7 | ||

| Kuthamanga kwa mpweya wa kompresa kwa zida m3/min | 0.3 | ||

| Zida zopangira mpweya wa tank / m3 | 0.5 | ||

| Zindikirani: kukula kwachidziwitso cha zida ndi kukula koyambira, koma osati tsatanetsatane wa kukula, kotero kukula uku kungonena.Zosiyanasiyana mbale, fyuluta adzakhala ndi kutalika ndi kulemera osiyana.Deta ya zida zothandizira pongotengera, imasinthidwa ndi kusefa munjira zosiyanasiyana. | |||

Kufotokozera zaukadaulo

| Chitsanzo | VSPFⅡ-3 | VSPFⅡ-6 | VSPFⅡ-9 | VSPFⅡ-12 | VSPFⅡ-15 | VSPFⅡ-18 | VSPFⅡ-21 | VSPFⅡ-24 |

| malo osefa/m2 | 3 | 6 | 9 | 12 | 15 | 18 | 21 | 24 |

| kukula kwa mbale / mm | 1.5m2 / wosanjikiza | |||||||

| mbale Qty/layer | 2 | 4 | 6 | 8 | 10 | 12 | 14 | 16 |

| kutalika/m | 3.7 | |||||||

| m'lifupi/m | 4.1 | |||||||

| kutalika/m | 2.6 | 2.8 | 3.2 | 3.7 | 4.2 | 4.6 | 5.1 | 5.5 |

| kulemera / T | 12 | 13 | 14 | 15 | 16 | 17 | 18 | 19 |

| hydraulic station power/KW | 11 | |||||||

| Pampu yotulutsa mutu/m | 28 | |||||||

| Pampu yotulutsa mpweya imayenda m3/h | 136 Zindikirani: ngati kuthamanga kwa extrusion kupitilira 1.3MPa, deta iyi ndi 164 | |||||||

| Mphamvu ya mpope yowonjezera/KW | 11 Zindikirani: ngati kuthamanga kwa extrusion kupitilira 1.3MPa, deta iyi ndi 15 | |||||||

Data Yothandizira Zida

| Kutsuka mapampu mutu /m | 68 | |||||||

| mpope wochapira chitoliro flowrate m3/h | 20 | |||||||

| Pampu yochapira nsalu mutu/m | 70 | |||||||

| Pampu yochapira nsalu imatuluka m3/h | 12 | |||||||

| Pampu yoledzera yothira mutu/m | 70 | |||||||

| Pampu yothirira madzi otsekemera m3/h | Malinga ndi slurry deta kusankha | |||||||

| Air drying pressure/Mpa | 0.8 | |||||||

| Air kompresa kuyenda kwa kuyanika mpweya m3/min | Malinga ndi slurry deta kusankha | |||||||

| Kuchuluka kwa thanki yowumitsa mpweya/m3 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 |

| Kuthamanga kwa mpweya kwa zida/Mpa | 0.7 | |||||||

| Air kompresa kuyenda kwa zida m3/min | 0.5 | |||||||

| Mphamvu ya thanki ya mpweya wa zida / m3 | 1 | |||||||

| Zindikirani: kukula kwachidziwitso cha zida ndi kukula koyambira, koma osati tsatanetsatane wa kukula, kotero kukula uku kungonena.Zosiyanasiyana mbale, fyuluta adzakhala ndi kutalika ndi kulemera osiyana.Deta ya zida zothandizira pongotengera, imasinthidwa ndi kusefa munjira zosiyanasiyana. | ||||||||

Kufotokozera zaukadaulo

| Chitsanzo VSPFⅢ | VSPFⅢ-18 | VSPFⅢ-24 | VSPFⅢ-30 | VSPFⅢ-36 | VSPFⅢ-42 | VSPFⅢ-48 | VSPFⅢ-54 | VSPFⅢ-60 | VSPFⅢ-66 |

| malo osefa/m2 | 18 | 24 | 30 | 36 | 42 | 48 | 54 | 60 | 66 |

| kukula kwa mbale / mm | 3.0m2/gawo | ||||||||

| mbale Qty/layer | 6 | 8 | 10 | 12 | 14 | 16 | 18 | 20 | 22 |

| kutalika/m | 5.1 | ||||||||

| m'lifupi/m | 5.5 | ||||||||

| kutalika/m | 4.3 | 4.5 | 4.9 | 5.4 | 5.8 | 6.3 | 6.8 | 7.2 | 7.7 |

| kulemera / T | 31 | 33 | 35 | 37 | 39 | 41 | 43 | 45 | 47 |

| hydraulic station powerKW | 22 | ||||||||

| Pampu yotulutsa mutu/m | 40 | 55 | |||||||

| Pampu yotulutsa mpweya imayenda m3/h | 136 Zindikirani: ngati kuthamanga kwa extrusion kupitilira 1.3MPa, deta iyi ndi 162 | 135 Zindikirani: ngati kuthamanga kwa extrusion kupitilira 1.3MPa, izi ndi 166 | |||||||

| Mphamvu ya mpope yowonjezera/KW | 15 Zindikirani: ngati kuthamanga kwa extrusion kupitilira 1.3MPa, deta iyi ndi 18.5 | 22 Zindikirani: ngati kuthamanga kwa extrusion kupitilira 1.3MPa, izi ndi 30 | |||||||

Data Yothandizira Zida

| Kuchapira mapampu mutu/m | 65 | ||||||||

| mpope wochapira zitoliro umayenda m3/h | 26 | ||||||||

| Pampu yochapira nsalu mutu/m | 70 | ||||||||

| Pampu yochapira nsalu imayenda m3/h | 16 | ||||||||

| Pampu yoledzera yothira mutu/m | 70 | ||||||||

| Pampu yamadzi yotsekemera imatuluka m3/h | Malinga ndi slurry deta kusankha | ||||||||

| Air drying pressure/Mpa | 0.8 | ||||||||

| Mayendedwe a mpweya wa kompresa poyanika mpweya m3/min | Malinga ndi slurry deta kusankha | ||||||||

| Kuchuluka kwa thanki yowumitsa mpweya/m3 | 8 | 10 | 10 | 12 | 12 | 15 | 15 | 20 | 20 |

| Kuthamanga kwa mpweya kwa zida/Mpa | 0.7 | ||||||||

| Kuthamanga kwa mpweya wa kompresa kwa zida m3/min | 0.5 | ||||||||

| Zida zopangira mpweya wa tank / m3 | 1 | ||||||||

| Zindikirani: kukula kwachidziwitso cha zida ndi kukula koyambira, koma osati tsatanetsatane wa kukula, kotero kukula uku kungonena.Zosiyanasiyana mbale, fyuluta adzakhala ndi kutalika ndi kulemera osiyana.Deta ya zida zothandizira pongotengera, imasinthidwa ndi kusefa munjira zosiyanasiyana. | |||||||||

Kufotokozera zaukadaulo

| Chitsanzo VSPFⅣ | VSPFⅣ-60 | VSPFⅣ-72 | VSPFⅣ-84 | VSPFⅣ-96 | VSPFⅣ-108 | VSPFⅣ-120 | VSPFⅣ-132 | VSPFⅣ-144 | VSPFⅣ-156 | VSPFⅣ-168 |

| Malo osefera/m2 | 60 | 72 | 84 | 96 | 108 | 120 | 132 | 144 | 156 | 168 |

| Kukula kwa mbale / mm | 6m2 / gawo | |||||||||

| Plate Qty / wosanjikiza | 10 | 12 | 14 | 16 | 18 | 20 | 22 | 24 | 26 | 28 |

| Utali/m | 7.1 | |||||||||

| M'lifupi/m | 5.5 | |||||||||

| Kutalika/m | 5.4 | 5.8 | 6.2 | 6.6 | 6.9 | 7.2 | 7.6 | 7.9 | 8.3 | 8.6 |

| Kulemera/T | 92 | 96 | 100 | 104 | 108 | 112 | 116 | 120 | 124 | 128 |

| Mphamvu ya Hydraulic station/KW | 30 | 37 | ||||||||

| Pampu yotulutsa mutu/m | 110 | 150 | ||||||||

| Pampu yotulutsa mpweya imayenda m3/h | 126 Zindikirani: ngati kuthamanga kwa extrusion kupitilira 1.3MPa, deta iyi ndi 168 | 128 Dziwani: ngati kuthamanga kwa extrusion kupitilira 1.3MPa, izi ndi 162.5 | ||||||||

| Mphamvu ya mpope yowonjezera/KW | 37 Zindikirani: ngati kuthamanga kwa extrusion kupitilira 1.3MPa, deta iyi ndi 45 | 55 Zindikirani: > 1.3MPa, deta iyi ndi 75 | ||||||||

Data Yothandizira Zida

| Kuchapira mapampu mutu/m | 72 | |||||||||

| mpope wochapira chitoliro flowrate m3/h | 36 | |||||||||

| Pampu yochapira nsalu mutu/m | 70 | |||||||||

| Pampu yochapira nsalu imatuluka m3/h | 20 | |||||||||

| Pampu yoledzera yothira mutu/m | 70 | |||||||||

| Pampu yothirira madzi otsekemera m3/h | Malinga ndi slurry deta kusankha | |||||||||

| Air drying pressure/Mpa | 0.8 | |||||||||

| Air kompresa kuyenda kwa kuyanika mpweya m3/min | Malinga ndi slurry deta kusankha | |||||||||

| Kuchuluka kwa thanki yowumitsa mpweya/m3 | 20 | 20 | 25 | 30 | 35 | 35 | 40 | 40 | 45 | 45 |

| Kuthamanga kwa mpweya kwa zida/Mpa | 0.7 | |||||||||

| Air kompresa kuyenda kwa zida m3/min | 1 | |||||||||

| Mphamvu ya thanki ya mpweya wa zida / m3 | 2 | |||||||||

| Zindikirani: kukula kwachidziwitso cha zida ndi kukula koyambira, koma osati tsatanetsatane wa kukula, kotero kukula uku kungonena.Zosiyanasiyana mbale, fyuluta adzakhala ndi kutalika ndi kulemera osiyana.Deta ya zida zothandizira pongotengera, imasinthidwa ndi kusefa munjira zosiyanasiyana. | ||||||||||

Minda Yofunsira

Amagwiritsidwa ntchito kwambiri mu zinyalala zamatauni, kusindikiza nsalu ndi utoto, electroplate, kupanga mapepala, zikopa, kupopera moŵa, kukonza chakudya, kutsuka malasha, mafakitale a petrochemical, chemistry, zitsulo, kulekana kwa mchere, pharmacy, ceramic industry sludge dewatering ndi zina zotero. kupanga mafakitale olimba-madzi olekanitsa kapena njira yamadzimadzi leaching.

| Ayi. | Dzina lachinthu | Kukula kwa chakudya (g/l) | Extrusion water ressure (MPa) | Makulidwe a keke (mm) | Chinyezi cha keke (%) | Kulemera kg/m2.h |

| 1 | 4A-zeolite | 150-295 | 1.4 | 35 | 19-22 | 190-200 |

| 2 | Sulfureti | ≈50 | 1.2 | 30 | 30 | 120 |

| 3 | Kutsogolera | ≈50 | 1.2 | 30 | 15-20 | 35 |

| 4 | Copper slag | 600 | 1.6 | 40 | 8~9 pa | 310 |

| 5 | Sulphate yamadzi otayira | 80 | 1.6 | 45 | 28-35 | 120-175 |

| 6 | Calcination golide michira | 300 | 1.6 | 35 | 14-18 | 300-340 |

| 7 | Superfine aluminiyamu hydroxide | 15-20% | 1.6 | 20 | 29.5-32 | 65 |

| 8 | Cu-Ni concentration | 66.7 | 1.6 | 30 | 9.78 | 257 |

| 9 | Mkuwa wokhazikika | 45-50 | 1.6 | 35 | 7.6 | 360 |

| 10 | Ndi concentration | 45-50 | 1.6 | 30 | 8 | 300-400 |

| 11 | Kununkhira kwa Tantalum-niobium | 1.6 | 20-25 | 200 | ||

| 12 | Malasha amoto | 30-35% | 1.6 | 30 | 16; 17 | 300 |

| 14 | Zovala zagolide pambuyo pa kuyandama | 20-30% | 1.6 | 35 | 12-18 | 300 |

| 15 | Mannitol | 1.5 | 12 | 35 | ||

| 16 | Zinc oxide ufa | 57% | 1.6 | 18 | 20 | 90 |

| 17 | Zotsalira za zinc oxide | 50% | 1.6 | 10 | 18-20 | 70 |

| 18 | Sulphur imayika | 10% | 1.6 | 20 | 25-35 | 200 |

Kapangidwe ka Zida

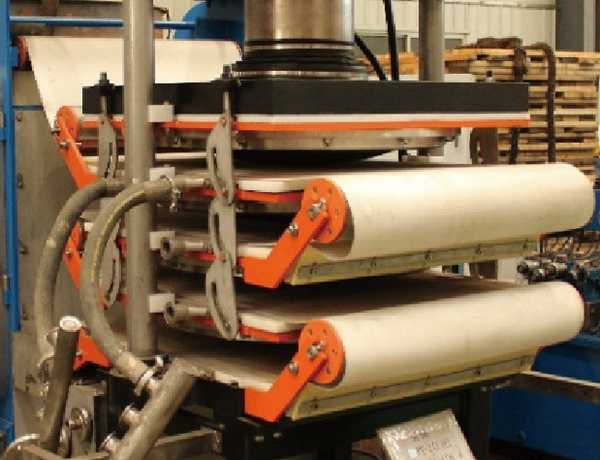

Mapangidwe Amagulu a Plate

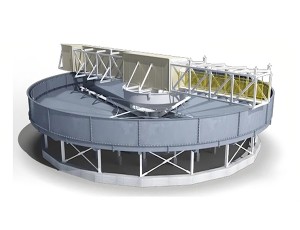

Kupanga Zithunzi

Zigawo Zazikulu

Kugwiritsa Ntchito Site