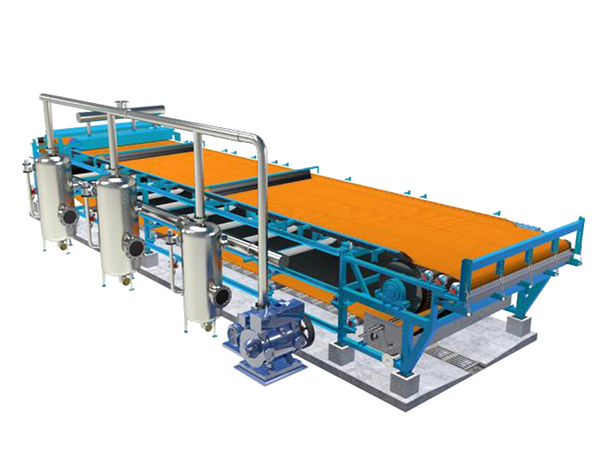

DU Filter Horizontal Vacuum Suunka

DU Filter Horizontal Vacuum Suunka

Mabaadi'da Hawlgelinta

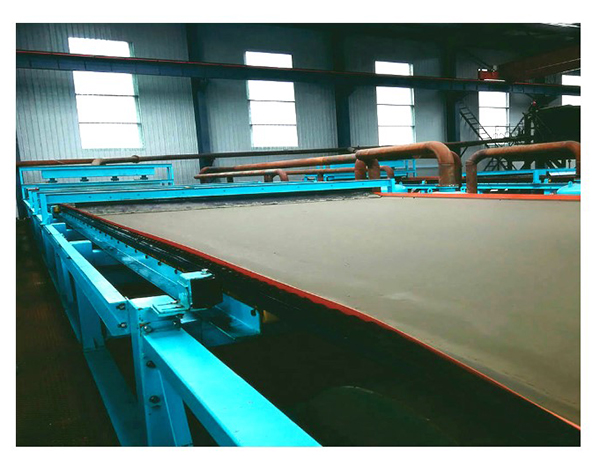

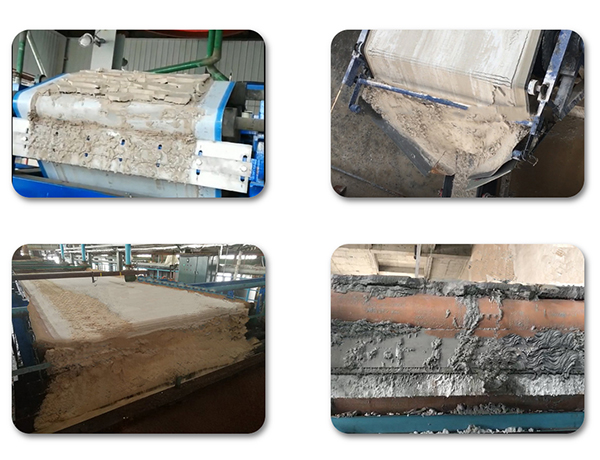

Qalabkani waxa uu qaadanayaa qolka faakuumka go'an, suunka caagga ah waxaa kaxeeya sanduuqa gearbox oo si joogto ah ugu socda qolka faakuumka, maradu waxay si isku mid ah ugu socotaa suunka caagga ah.Suunka is jiid jiidka ee silbashada qolka faakuumka samaynta qaab dhismeedka biyaha lagu xidho suunka caagga ah.Quudinta slurry ee marada si habsami leh oo siman iyadoo quudinaysa hopper.Marka qolka faakuumku ku xidhmo nidaamka faakuumka, meesha shaandhaynta leh nuugista faakuumka ayaa lagu samayn doonaa suunka caagga ah, sifaynta marada marada iyo qulqulka jeexjeexyada iyo godadka suunka caagga ilaa qolka faakuumka, adkaha ayaa sameeyay keega dusha marada.Shaandhaynta qolka faakuumka ee ay soo dayso haanta faakuumka.Ku dhaqaaqida suunka caagga ah, keega wuxuu u guurayaa meesha lagu dhaqo keega iyo meesha lagu qalajiyo si isdaba joog ah, ka dibna u gal aagga keega.Ka dib marka la shubo keega, marada lagu dhaqo habka dhaqida oo geli wareegga xiga ee shaandhaynta.

Astaamaha

● Naqshadaynta qaab-dhismeedka, isu-ururinta dabacsan iyo gaadiid ku habboon ayaa loo hirgeliyay qaab-dhismeedka.Sidoo kale, waxay keeni kartaa dhammaan qalabka la soo ururiyey ka dib marka la isku daro iyo tijaabinta tijaabada.

● Dharka shaandhada iyo suunka caagga ah ee si isku mid ah u shaqaynaya ayaa lagu dhejiyaa shaandhada, kaas oo la dhamayn karo habka quudinta, shaandhaynta, dhaqidda, qalajinta iyo dhaqidda dharka joogtada ah.

● Kantaroolka fog iyo kontoroolka gudaha waa la is weydaarsan karaa si loo gaaro hawlgallo aan cidi wadin.

● Taageerada suunka caagga ah, waxaan isticmaali karnaa rollers, barkin hawo, suunka suunka iyo suumanka isku dhaca ee badan si aan u yareyno iska caabinta suunka caagga ah oo aan u dheereyno waqtiga suunka caagga ah.

● Biyo nadiif ah u isticmaal ama biyo nadiif ah dhaqida keegga, oo u soo ururi shaandhaynta qaybo.

● U isticmaal biyo cadaadis sare ah oo aad ku dhaqdo maro si aad u kordhiso saameynta soo cusboonaysiinta marada iyo cimriga.

● Noocyada sifaynta waxaa ka mid ah dareere toos ah, dheecaan heer sare ah iyo dheecaan kaabayaal ah.

● Daboolka gaaska ama daaqadaha caaga ah ee aluminiumka waxaa loo qaabayn karaa qayb xiran ama gebi ahaanba lagu xidho daboolka qayb ahaan ama ururinta dhexe ee gaaska kacsan ama uumiga dareeraha.

Tilmaamaha Farsamada

| Aagga shaandhaynta | Balaadhka waxtarka leh | Dhererka waxtarka leh | Dhererka qaab-dhismeedka | Qaabka ballac ahaan | Qaabka dhererka | Miisaanka | Vacuum isticmaalka |

| 2 | 500 | 4000 | 8100 | 1100 | 2070 | 5.5 | 8 |

| 3 | 6000 | 10100 | 6 | 12 | |||

| 4 | 8000 | 12100 | 6.5 | 16 | |||

| 5 | 10000 | 14100 | 7 | 18 | |||

| 6 | 12000 | 16100 | 7.6 | 22 | |||

| 8 | 1000 | 8000 | 12100 | 1600 | 2070 | 8.8 | 25 |

| 10 | 10000 | 14100 | 9.6 | 28 | |||

| 12 | 12000 | 16100 | 10.4 | 30 | |||

| 14 | 14000 | 18100 | 11.1 | 33 | |||

| 10.4 | 1300 | 8000 | 12100 | 1900 | 2170 | 9.8 | 28 |

| 13 | 10000 | 14100 | 10.8 | 30 | |||

| 15.6 | 12000 | 16100 | 11.5 | 35 | |||

| 18.2 | 14000 | 18100 | 13.2 | 38 | |||

| 20.8 | 16000 | 20100 | 15.1 | 42 | |||

| 20 | 2000 | 10000 | 14100 | 2700 | 2170 | 14.2 | 40 |

| 24 | 12000 | 16100 | 17.8 | 48 | |||

| 28 | 14000 | 18100 | 20.2 | 52 | |||

| 32 | 16000 | 20100 | 23.6 | 65 | |||

| 20 | 2500 | 8000 | 12100 | 3200 | 2270 | 14.8 | 40 |

| 25 | 10000 | 14100 | 18.6 | 50 | |||

| 30 | 12000 | 16100 | 22.2 | 60 | |||

| 35 | 14000 | 18100 | 26 | 70 | |||

| 40 | 16000 | 20100 | 29.8 | 80 | |||

| 50 | 20000 | 24100 | 41 | 95 | |||

| 30 | 3000 | 10000 | 14100 | 3750 | 2270 | 22.8 | 60 |

| 36 | 12000 | 16100 | 27.5 | 72 | |||

| 42 | 14000 | 18100 | 32.5 | 85 | |||

| 54 | 18000 | 22100 | 45 | 105 | |||

| 60 | 20000 | 24100 | 50.5 | 120 | |||

| 48 | 4000 | 12000 | 16100 | 4800 | 2470 | 39.5 | 92 |

| 56 | 14000 | 18100 | 46.8 | 110 | |||

| 64 | 16000 | 20100 | 52.6 | 120 | |||

| 72 | 18000 | 22100 | 58.3 | 145 | |||

| 80 | 20000 | 24100 | 63 | 160 | |||

| 144 | 4500 | 32500 | 41200 | 7100 | 5500 | 70 | 360 |

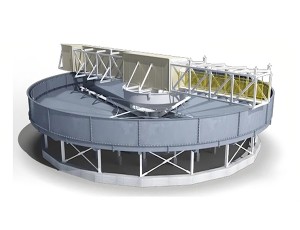

Habka socodka jaantuska

Qaybaha ugu muhiimsan

Sawirada goobaha shaqada