Nidaamka Qalajinta Dhuunta/Dhuxusha

Nidaamka Qalajinta Dhuunta/Dhuxusha

Sharaxaada Nidaamka

Habka ugu dhaqameed ee digada xooluhu waa in loo iibiyo sida digada beeraha oo qiimo jaban oo si toos ah loogu isticmaalo sida bacriminta beeraha, qiimaha dhaqaaluhu maaha in si buuxda loo baadho oo laga faa'iidaysto.Runtii kuwani waa calafka qaaliga ah ee calafka iyo bacriminta, haddii la horumariyo lagana faa’iidaysto, waxa ay muhiimad weyn u yeelan doontaa wax soo saarka bacriminta organic, horumarinta warshadaynta iyo taranta, kor u qaadida wax soo saarka beeraha iyo dakhliga, badbaadinta tamarta iyo Cunto cagaaran oo aan wasakh ahayn, horumarinta beeraha cagaaran, ilaalinta deegaanka iyo caafimaadka dadka.

Iyada oo kor u kaca joogtada ah ee wacyiga dadka ee ilaalinta deegaanka, iyo tignoolajiyada qalajinta dhoobada ayaa sidoo kale ku jira horumarka degdega ah, hal-abuurnimada joogtada ah iyo hagaajinta ayaa sidoo kale ku dhacda dhinacyada tamarta tamarta, badbaadada, isku halaynta, waaraya.Nidaamka qalajinta dhoobada ee shirkadeena ayaa hoos u dhigi doonta biyaha wasakhda ah ee laga bilaabo 80 + 10% ilaa 20 + 10%.Faa'iidooyinka nidaamkayaga waa sida soo socota:

1. Miisaanka dhoobada qallalan waxaa lagu dhimi karaa 1/4 miisaanka walxaha qoyan ka hor inta aan la qalajin, taas oo si weyn u yaraynaysa cadaadiska deegaanka iyo dhaqaalaha ee shirkadda;

2. Heerkulka gelitaanka hawada ee qalajiyaha waa 600-800 ℃, waxaana loo isticmaali karaa jeermiska, deodorant, iwm isla mar ahaantaana qalajinta, iyo dammaanad lagu kalsoonaan karo ayaa la siin doonaa isticmaalka alaabta la qalajiyey;

3. Alaabooyinka la qalajiyey waxaa loo isticmaali karaa sida quudinta, bacriminta, shidaalka, qalabka dhismaha, alaabta ceeriin ee soo saarista biraha culus, si loo xaqiijiyo isticmaalka qashinka.

Walaxda biyo la'aanta ah waxaa loo qaadi doonaa madaxa quudinta ee qalajiyaha iyada oo loo marayo gudbiyaha furaha ka dib marka la kala firdhiyo, ka dibna waxaa loo diri doonaa gudaha qalajiyaha iyada oo loo marayo feederiyaha daboolka wareega ee aan tamar lahayn (teknoolajiyada patent ee shirkadeena), oo dhex marta dhowr soo socda meelaha shaqada ka dib markii la galo qalajiyaha:

1. Aagga hogaaminta alaabta

Walaxda ayaa la xiriiri doonta heerkulka sare ee hawada cadaadiska xun ka dib marka la galo aaggan oo biyo badan ayaa si degdeg ah u soo bixi doona, iyo dhoobada looma samayn karo walxo dhegdheg ah oo hoos yimaada walaaqaya saxanka weyn ee xagasha hagaha.

2. Meesha nadiifinta

Daahyada alaabta ayaa la samayn doonaa marka dhoobada kor loo qaado meeshan, waxayna keeni doontaa walxaha ku dheggan gidaarka dhululubada inta ay hoos u dhacayso, iyo qalabka nadiifinta ayaa lagu rakibay goobtan saxan walaaqaya wakhtiga, silsiladda saamaynta leh, saxanka saamaynta leh), dhoobada si dhakhso ah ayaa looga saari karaa gidaarka dhululubada qalabka nadiifinta, iyo qalabka nadiifinta ayaa sidoo kale burburin kara alaabta isku xiran, si ay u kordhiso aagga kulaylka, korodhka waqtiga kulaylka isweydaarsiga, iska ilaali jiilka ifafaale tunnel dabaysha, hagaajin heerka qalajinta;

3. Meesha saxanka wax lagu qaadi karo

Goobtani waa meesha heerkulka hooseeya ee qalajinta, slime ee goobtani waa qoyaan hoose iyo xaalad dabacsan, mana jirto wax ifafaale ah oo meeshan ah, alaabta la dhammeeyey waxay gaarayaan shuruudaha qoyaanka ka dib kulaylka, ka dibna geli finalka. aagga dheecaanka;

4. Meesha lagu shubo

Meeshan dhululubada qalajiyaha kuma jiraan taargooyin wax kicinaya, oo walaxda waxay ku soo rogi doontaa dekedda

Walaxda ayaa si tartiib tartiib ah u furfuran ka dib marka la qalajiyo, waxaana laga soo saaraa dhammaadka soo dajinta, ka dibna loo diro goobta loogu talagalay qalabka gudbinta, iyo boodhka wanaagsan ee laga soo saaro gaaska dabada waxaa aruuriya boodhka ururiyaha.

Hawada kulul waxay gashaa mashiinka qalajinta dhamaadka quudinta, heerkulku si tartiib tartiib ah ayaa loo dhimaa isla mar ahaantaana wareejinta kulaylka walaxda, iyo uumiga biyaha ee laga soo saaro nuugista marawaxada qabyada ah, ka dibna hawada ku sii daaya ka dib habaynta .

Codsiga qalajinta ka dib

Dib u warshadaynta birta culus

Inta lagu jiro habka nadiifinta biyaha wasakhda ah ee warshadda dhalaalaysa, warshadda daabacaadda guddiga wareegga, warshadaha korontada ku shaqeeya iyo shirkado kale, iyo dhoobada la soo saaro waxay ka kooban tahay biro badan oo culus (naxaas, nikkel, dahab, qalin, iwm.).Waxaa jiri doona wasakh weyn haddii walxahaas birta ah la miiro, laakiin faa'iidooyin dhaqaale oo badan ayaa la gaari karaa ka dib marka la soo saaro oo la sifeeyo.

Korontada kicinta

Qiyaasta qiyaasta calorific ee dhoobada la qalajiyey waa 1300 ilaa 1500 kalori, saddex tan oo dhoobo qalalan ah waxay u dhigantaa hal tan oo 4500 kcal ah, kaas oo lagu gubi karo foornada lagu qaso dhuxusha.

Qalabka dhismaha

Isku darka la taaban karo, admixture sibidhka iyo wax soo saarka ee laamiga encaustic leben, leben permeable, looxa fiber, si ay u sameeyaan leben by ku daray galay dhoobada, xooggeedu waxa ay la mid ah leben cas caadiga ah, iyo waxa ay la xad gaar ah oo kulaylka, in habka loo shido. leben, gubashada lama filaanka ah ayaa la gaari karaa si loo kordhiyo kuleylka.

Bacriminta dabiiciga ah

Xabagta la qalajiyey waxay ku dhalaali doontaa bacriminta organic tayada sare leh ka dib marka lagu daro digada lo'da, oo leh waxtarka bacriminta wanaagsan, badbaadada iyo isticmaalka habboon, iyo caabbinta cudurada iyo kor u qaadista koritaanka, taas oo sidoo kale bacrimin karta ciidda.

Isticmaalka beeraha

Waxaa ku jira maado badan oo N, P iyo K ah oo dhoobada ku jira, aad bayna uga badan tahay tan digada doofaarka, digada lo'da iyo digada digaagga, waxaana ku jira iskudhis dabiici ah oo qani ah.Waxaa loo isticmaali karaa sidii bacriminta beeraha ka dib habaynta nidaamka qalajinta dhoobada, waxayna samayn kartaa carro tayo leh iyada oo loo marayo dib-u-qeexidda qashin-qubka.

Qiyaasaha Farsamada

| Qaabka | Dhexroor dhululubo (mm) | Dhererka dhululubo (mm) | Mugga dhululubo (m3) | Xawaaraha dhululubo (r/min) | Awood (kW) | Miisaanka (t) |

| VS0.6x5.8 | 600 | 5800 | 1.7 | 1-8 | 3 | 2.9 |

| VS0.8x8 | 800 | 8000 | 4 | 1-8 | 4 | 3.5 |

| VS1x10 | 1000 | 10000 | 7.9 | 1-8 | 5.5 | 6.8 |

| VS1.2x5.8 | 1200 | 5800 | 6.8 | 1-6 | 5.5 | 6.7 |

| VS1.2x8 | 1200 | 8000 | 9 | 1-6 | 5.5 | 8.5 |

| VS1.2x10 | 1200 | 10000 | 11 | 1-6 | 7.5 | 10.7 |

| VS1.2x11.8 | 1200 | 11800 | 13 | 1-6 | 7.5 | 12.3 |

| VS1.5x8 | 1500 | 8000 | 14 | 1-5 | 11 | 14.8 |

| VS1.5x10 | 1500 | 10000 | 17.7 | 1-5 | 11 | 16 |

| VS1.5x11.8 | 1500 | 11800 | 21 | 1-5 | 15 | 17.5 |

| VS1.5x15 | 1500 | 15000 | 26.5 | 1-5 | 15 | 19.2 |

| VS1.8x10 | 1800 | 10000 | 25.5 | 1-5 | 15 | 18.1 |

| VS1.8x11.8 | 1800 | 11800 | 30 | 1-5 | 18.5 | 20.7 |

| VS1.8x15 | 1800 | 15000 | 38 | 1-5 | 18.5 | 26.3 |

| VS1.8x18 | 1800 | 18000 | 45.8 | 1-5 | 22 | 31.2 |

| VS2x11.8 | 2000 | 11800 | 37 | 1-4 | 18.5 | 28.2 |

| VS2x15 | 2000 | 15000 | 47 | 1-4 | 22 | 33.2 |

| VS2x18 | 2000 | 18000 | 56.5 | 1-4 | 22 | 39.7 |

| VS2x20 | 2000 | 20000 | 62.8 | 1-4 | 22 | 44.9 |

| VS2.2x11.8 | 2200 | 11800 | 44.8 | 1-4 | 22 | 30.5 |

| VS2.2x15 | 2200 | 15000 | 53 | 1-4 | 30 | 36.2 |

| VS2.2x18 | 2200 | 18000 | 68 | 1-4 | 30 | 43.3 |

| VS2.2x20 | 2200 | 20000 | 76 | 1-4 | 30 | 48.8 |

| VS2.4x15 | 2400 | 15000 | 68 | 1-4 | 30 | 43.7 |

| VS2.4x18 | 2400 | 18000 | 81 | 1-4 | 37 | 53 |

| VS2.4x20 | 2400 | 20000 | 91 | 1-4 | 37 | 60.5 |

| VS2.4x23.6 | 2400 | 23600 | 109 | 1-4 | 45 | 69.8 |

| VS2.8x18 | 2800 | 18000 | 111 | 1-3 | 45 | 62 |

| VS2.8x20 | 2800 | 20000 | 123 | 1-3 | 55 | 65 |

| VS2.8x23.6 | 2800 | 23600 | 148 | 1-3 | 55 | 70 |

| VS2.8x28 | 2800 | 28000 | 172 | 1-3 | 75 | 75 |

| VS3x20 | 3000 | 20000 | 141 | 1-3 | 55 | 75 |

| VS3x23.6 | 3000 | 23600 | 170 | 1-3 | 75 | 85 |

| VS3x28 | 3000 | 28000 | 198 | 1-3 | 90 | 91 |

| VS3.2x23.6 | 3200 | 23600 | 193 | 1-3 | 90 | 112 |

| VS3.2x32 | 3200 | 32000 | 257 | 1-3 | 110 | 129 |

| VS3.6x36 | 3600 | 36000 | 366 | 1-3 | 132 | 164 |

| VS3.8x36 | 3800 | 36000 | 408 | 1-3 | 160 | 187 |

| VS4x36 | 4000 | 36000 | 452 | 1-3 | 160 | 195 |

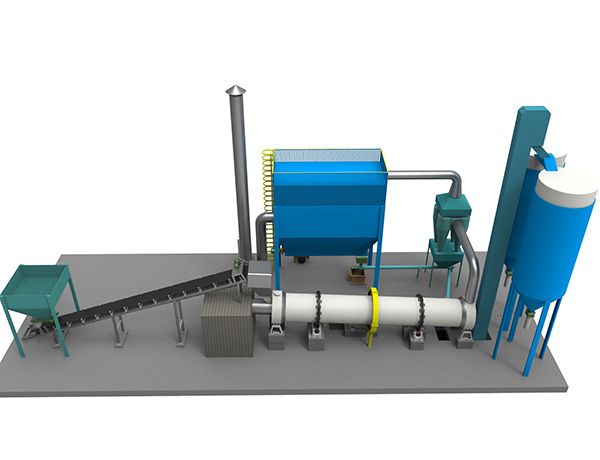

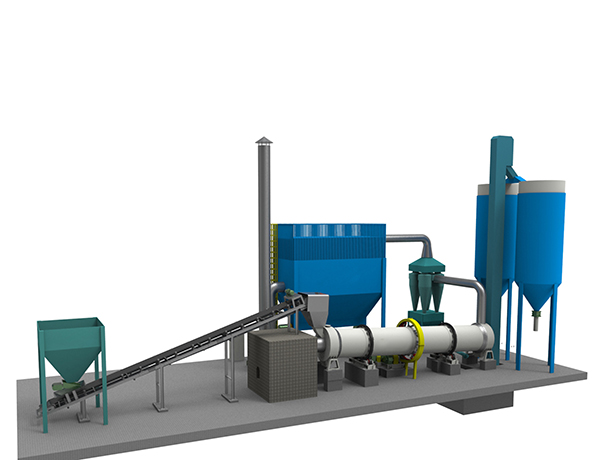

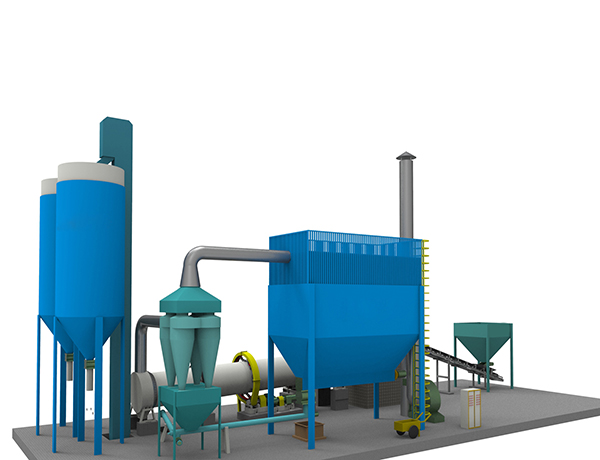

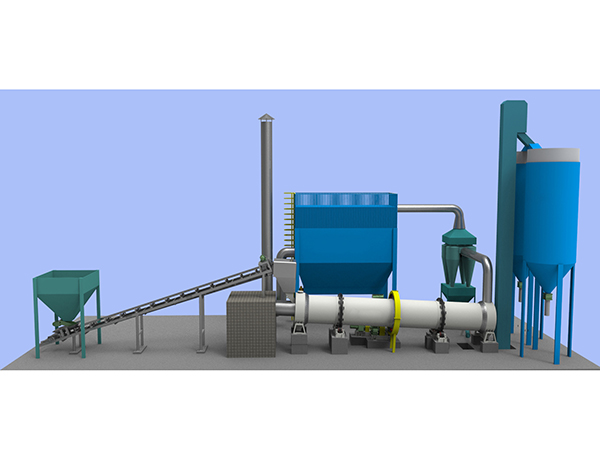

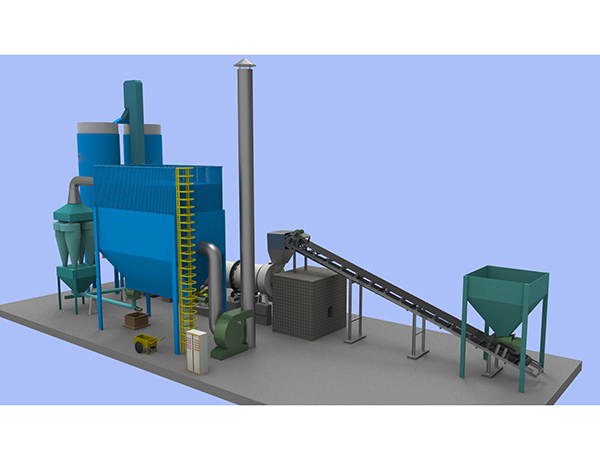

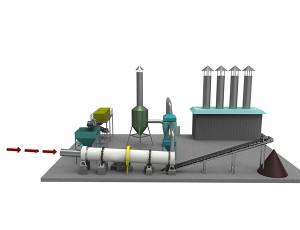

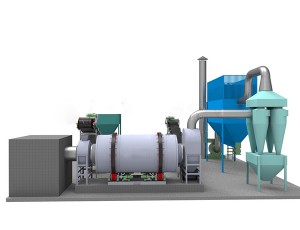

Sawirada Goobaha Shaqada