VSPF Raadsan Filter Press

VSPF Raadsan Filter Press

Tilmaamaha Qalabka

u adeegso qaab-dhismeed isku xidhan oo taarikada ah, isticmaal aaladda hagaha caawimada si aad hawl-galku u noqoto mid xasiloon.

● Isku-dubarid shaandhaynta, saarista, dhaqida, qalajinta hawada, dareerinta keega iyo dhar dhaqidda si wadajir ah.

● Cadaadiska extrusion-ka ilaa 1.6MPa, oo si weyn loogu isticmaalo beerta kaas oo leh shuruudo kala duwan oo loogu talagalay qoyaanka keega.

● 4.isticmaal nidaamka xakamaynta wadista hydraulic, ka dhig hawlgalka mid xasiloon iyo isticmaalka tamarta yar.

Isku-dubarid PLC, HMI iyo nidaamka xakamaynta aaladaha iwm si wada jir ah oo caqli leh, waxay ka dhigaysaa shaandhada mid hufan oo fudud.

● Isticmaal qalabka nadiifinta biyaha cadaadiska sare si aad uga dhigto dhar dhaqidda mid waxtar leh.

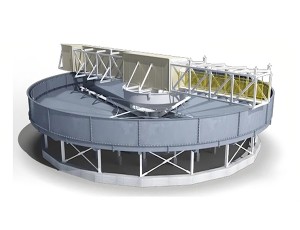

● Nakhshad leh qol wareeg ah, qaab-dhismeedku si caqli-gal ah, hufnaantuna aad u caan ah.

Mabaadi'da Hawlgelinta

1. Shaandhaynta: marka kooxda taarikada xiran, bamka slurry si ay u shaandhayso, isticmaali tuubada qaybiyey quudinta slurry qol kasta slurry, iyo sifaynta marada si ay u shaandhayso jir iyo dheecaan ka baxay, adag sameeyey keega on dusha marada.

2, Extrusion: biyo cadaadis sare quudin galay qolka sare ee diaphragm caag, ka dhigi diaphragm ballaariyo iyo extruding keega iyo dareeraha la extruding ka soo cake doonaa.

3. Keega dhaqida: biyaha lagu dhaqo quudinta galay qol slurry dhex dabool tuubada qaybiyey on keega si buuxda, hoos cadaadiska, biyaha lagu dhaqo maraa keega iyo marada si ay u sii daayo baxay.

4. Qalajinta hawada: hawada cufan iyada oo loo marayo tuubada quudinta qaybinta qolka slurry iyo riixaya diaphragm caag, ka dhigi biyaha-cadaadiska sare ee diaphragm caag ah si ay u sii daayo, iyo hawada cadaadisay dhex maraa keega iyo qaado dareere baxay si loo yareeyo qoyaan cake ah si ay heerka ugu hooseeya.

5. Keega sii dayn: marka la dhammeeyo habka hawo-qallajinta, furo kooxda taarikada, nidaamka drive ka dhigaysa marada socda iyo dheecaan keega baxay labada dhinac ee filter isku mar.

Fiiro gaar ah: Fadlan sida waafaqsan xaaladda dhabta ah ee isticmaalka si loo hagaajiyo waqtiyada ka saarista iyo habka hawo-qallajinta.

Habka socodka jaantuska

Taxanaha Qalabka

Tilmaamaha Farsamada

| Model/VSPF-ga | VSPFⅠ-1 | VSPFⅠ-2 | VSPFⅠ-3 |

| Aagga shaandhaynta/m2 | 1 | 2 | 3 |

| Cabbirka saxanka/mm | 0.5m2/lakab | ||

| Saxan qty/lakab ah | 2 | 4 | 6 |

| Dhererka/m | 2.5 | ||

| Ballaca/m | 1.5 | ||

| Dhererka/m | 2 | 2.2 | 2.5 |

| Miisaanka/T | 8 | 9 | 10 |

| Korontada saldhigga Haydarooliga/KW | 7.5 | ||

| Madax/m | 167 | ||

| Bamka soo saarista qulqul m3/h | 8 | ||

| Awooda bamka soo saarista/KW | 7.5 | ||

Xogta Qalabka Kaalmada

| Madax/m | 70 | ||

| Bamka dhaqida tuubooyinka socodka m3/h | 10 | ||

| Madax/m | 70 | ||

| Bamka dhaqida marada socodka m3/h | 10 | ||

| Madaxa bamka quudinta qulqulaya | 70 | ||

| Bamka quudinta qulqulka qulqulka m3/saacaddii | Marka loo eego xogta slurry ee la dooranayo | ||

| Cadaadiska hawada qalajinta/Mpa | 0.8 | ||

| Hawada kombaresarada socodka hawada qalajinta m3/min | 0.5 | 1 | 1.5 |

| Mugga haanta qalajinta hawada / m3 | 1 | 2 | 3 |

| Cadaadiska hawada ee qalabka/Mpa | 0.7 | ||

| Qulqulka hawada ee qalabka m3/min | 0.3 | ||

| Qalabka haanta hawada mugga/m3 | 0.5 | ||

| Fiiro gaar ah: cabbirka dulucda qalabku waa cabbirka aasaasiga ah, laakiin maaha cabbirka tafaasiisha, markaa cabbirkan oo keliya tixraac.Qalabka kala duwan ee saxanka, filtarka ayaa yeelan doona dherer iyo miisaan kala duwan.Xogta qalabka caawimada ee tixraaca kaliya, waxay ku beddeli doontaa waxqabadka shaandhaynta ee slurry kala duwan. | |||

Tilmaamaha Farsamada

| Qaabka | VSPFⅡ-3 | VSPFⅡ-6 | VSPFⅡ-9 | VSPFⅡ-12 | VSPFⅡ-15 | VSPFⅡ-18 | VSPFⅡ-21 | VSPFⅡ-24 |

| aagga filter/m2 | 3 | 6 | 9 | 12 | 15 | 18 | 21 | 24 |

| cabbirka saxanka/mm | 1.5m2 / lakab | |||||||

| saxan Qty/lakab | 2 | 4 | 6 | 8 | 10 | 12 | 14 | 16 |

| dhererka/m | 3.7 | |||||||

| ballac/m | 4.1 | |||||||

| dhererka/m | 2.6 | 2.8 | 3.2 | 3.7 | 4.2 | 4.6 | 5.1 | 5.5 |

| miisaanka/T | 12 | 13 | 14 | 15 | 16 | 17 | 18 | 19 |

| Korontada saldhigga biyo-biyoodka/KW | 11 | |||||||

| Madax/m | 28 | |||||||

| Bamka soo saarista socodka m3/h | 136 Ogow: haddii cadaadiska extrusion ka badan yahay 1.3MPa, xogtani waa 164 | |||||||

| Awooda bamka soo saarista/KW | 11 Ogow: haddii cadaadiska extrusion ka badan yahay 1.3MPa, xogtani waa 15 | |||||||

Xogta Qalabka Kaalmada

| Madaxa bamka dhaqida tuubada | 68 | |||||||

| Bamka dhaqida tuubooyinka qulqulka m3/h | 20 | |||||||

| Madax/m | 70 | |||||||

| Bamka dhaqida marada qulqulid m3/h | 12 | |||||||

| Madaxa bamka quudinta qulqulaya | 70 | |||||||

| Bamka quudinta qulqulka qulqulka m3/h | Marka loo eego xogta slurry ee la dooranayo | |||||||

| Cadaadiska hawada qalajinta/Mpa | 0.8 | |||||||

| Hawada kombaresarada qulqulka hawada qalajin m3/min | Marka loo eego xogta slurry ee la dooranayo | |||||||

| Mugga haanta qalajinta hawada / m3 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 |

| Cadaadiska hawada ee qalabka/Mpa | 0.7 | |||||||

| Qulqulka hawo kombaresarada ee agabka m3/min | 0.5 | |||||||

| Qalabka haanta hawada mugga/m3 | 1 | |||||||

| Fiiro gaar ah: cabbirka dulucda qalabku waa cabbirka aasaasiga ah, laakiin maaha cabbirka tafaasiisha, markaa cabbirkan oo keliya tixraac.Qalabka kala duwan ee saxanka, filtarka ayaa yeelan doona dherer iyo miisaan kala duwan.Xogta qalabka caawimada ee tixraaca kaliya, waxay ku beddeli doontaa waxqabadka shaandhaynta ee slurry kala duwan. | ||||||||

Tilmaamaha Farsamada

| Habka VSPF | VSPFⅢ-18 | VSPFⅢ-24 | VSPFⅢ-30 | VSPFⅢ-36 | VSPFⅢ-42 | VSPFⅢ-48 | VSPFⅢ-54 | VSPFⅢ-60 | VSPFⅢ-66 |

| aagga filter/m2 | 18 | 24 | 30 | 36 | 42 | 48 | 54 | 60 | 66 |

| cabbirka saxanka/mm | 3.0m2/lakab | ||||||||

| saxan Qty/lakab | 6 | 8 | 10 | 12 | 14 | 16 | 18 | 20 | 22 |

| dhererka/m | 5.1 | ||||||||

| ballac/m | 5.5 | ||||||||

| dhererka/m | 4.3 | 4.5 | 4.9 | 5.4 | 5.8 | 6.3 | 6.8 | 7.2 | 7.7 |

| miisaanka/T | 31 | 33 | 35 | 37 | 39 | 41 | 43 | 45 | 47 |

| Awoodda saldhigga haydarooliga | 22 | ||||||||

| Madax/m | 40 | 55 | |||||||

| Bamka soo saarista socodka m3/h | 136 Ogow: haddii cadaadiska extrusion ka badan yahay 1.3MPa, xogtani waa 162 | 135 Ogow: haddii cadaadiska extrusion ka badan yahay 1.3MPa, xogtani waa 166 | |||||||

| Awooda bamka soo saarista/KW | 15 Ogow: haddii cadaadiska extrusion ka badan yahay 1.3MPa, xogtani waa 18.5 | 22 Ogow: haddii cadaadiska extrusion ka badan yahay 1.3MPa, xogtani waa 30 | |||||||

Xogta Qalabka Kaalmada

| Madax/m | 65 | ||||||||

| Bamka dhaqida tuubooyinka socodka m3/h | 26 | ||||||||

| Madax/m | 70 | ||||||||

| Bamka dhaqida marada socodka m3/h | 16 | ||||||||

| Madaxa bamka quudinta qulqulaya | 70 | ||||||||

| Bamka quudinta qulqulka qulqulka m3/saacaddii | Marka loo eego xogta slurry ee la dooranayo | ||||||||

| Cadaadiska hawada qalajinta/Mpa | 0.8 | ||||||||

| Hawada kombaresarada socodka hawada qalajinta m3/min | Marka loo eego xogta slurry ee la dooranayo | ||||||||

| Mugga haanta qalajinta hawada / m3 | 8 | 10 | 10 | 12 | 12 | 15 | 15 | 20 | 20 |

| Cadaadiska hawada ee qalabka/Mpa | 0.7 | ||||||||

| Qulqulka hawada ee qalabka m3/min | 0.5 | ||||||||

| Qalabka haanta hawada mugga/m3 | 1 | ||||||||

| Fiiro gaar ah: cabbirka dulucda qalabku waa cabbirka aasaasiga ah, laakiin maaha cabbirka tafaasiisha, markaa cabbirkan oo keliya tixraac.Qalabka kala duwan ee saxanka, filtarka ayaa yeelan doona dherer iyo miisaan kala duwan.Xogta qalabka caawimada ee tixraaca kaliya, waxay ku beddeli doontaa waxqabadka shaandhaynta ee slurry kala duwan. | |||||||||

Tilmaamaha Farsamada

| Habka VSPF | VSPFⅣ-60 | VSPFⅣ-72 | VSPFⅣ-84 | VSPFⅣ-96 | VSPFⅣ-108 | VSPFⅣ-120 | VSPFⅣ-132 | VSPFⅣ-144 | VSPFⅣ-156 | VSPFⅣ-168 |

| Aagga shaandhaynta/m2 | 60 | 72 | 84 | 96 | 108 | 120 | 132 | 144 | 156 | 168 |

| Cabbirka saxanka/mm | 6m2/lakab | |||||||||

| Saxan Qty/lakab | 10 | 12 | 14 | 16 | 18 | 20 | 22 | 24 | 26 | 28 |

| Dhererka/m | 7.1 | |||||||||

| Ballaca/m | 5.5 | |||||||||

| Dhererka/m | 5.4 | 5.8 | 6.2 | 6.6 | 6.9 | 7.2 | 7.6 | 7.9 | 8.3 | 8.6 |

| Miisaanka/T | 92 | 96 | 100 | 104 | 108 | 112 | 116 | 120 | 124 | 128 |

| Korontada saldhigga Haydarooliga/KW | 30 | 37 | ||||||||

| Madax/m | 110 | 150 | ||||||||

| Bamka soo saarista socodka m3/h | 126 Ogow: haddii cadaadiska extrusion ka badan yahay 1.3MPa, xogtani waa 168 | 128 Ogow: haddii cadaadiska extrusion ka badan yahay 1.3MPa, xogtani waa 162.5 | ||||||||

| Awooda bamka soo saarista/KW | 37 Ogow: haddii cadaadiska extrusion ka badan yahay 1.3MPa, xogtani waa 45 | 55 Fiiro gaar ah:> 1.3MPa, xogtani waa 75 | ||||||||

Xogta Qalabka Kaalmada

| Madax/m | 72 | |||||||||

| Bamka dhaqida tuubooyinka qulqulka m3/h | 36 | |||||||||

| Madax/m | 70 | |||||||||

| Bamka dhaqida marada qulqulid m3/h | 20 | |||||||||

| Madaxa bamka quudinta qulqulaya | 70 | |||||||||

| Bamka quudinta qulqulka qulqulka m3/h | Marka loo eego xogta slurry ee la dooranayo | |||||||||

| Cadaadiska hawada qalajinta/Mpa | 0.8 | |||||||||

| Hawada kombaresarada qulqulka hawada qalajin m3/min | Marka loo eego xogta slurry ee la dooranayo | |||||||||

| Mugga haanta qalajinta hawada / m3 | 20 | 20 | 25 | 30 | 35 | 35 | 40 | 40 | 45 | 45 |

| Cadaadiska hawada ee qalabka/Mpa | 0.7 | |||||||||

| Qulqulka hawo kombaresarada ee agabka m3/min | 1 | |||||||||

| Qalabka haanta hawada mugga/m3 | 2 | |||||||||

| Fiiro gaar ah: cabbirka dulucda qalabku waa cabbirka aasaasiga ah, laakiin maaha cabbirka tafaasiisha, markaa cabbirkan oo keliya tixraac.Qalabka kala duwan ee saxanka, filtarka ayaa yeelan doona dherer iyo miisaan kala duwan.Xogta qalabka caawimada ee tixraaca kaliya, waxay ku beddeli doontaa waxqabadka shaandhaynta ee slurry kala duwan. | ||||||||||

Goobaha Codsiga

Waxaa si weyn loo isticmaalaa in bulaacada magaalada, daabacaadda dunta iyo dheehidda, electroplate, waraaqaha, maqaar, breing, diyaarinta cuntada, dhaqidda dhuxusha, warshadaha petrochemical, kimistari, metallurgy, kala soocidda macdanta, farmashiyaha, dhoobada warshadaha dhoobada iyo wixii la mid ah, sidoo kale loo isticmaalo in soosaarka warshadaha kala soocida dareeraha adag ama habka dareeraha dareeraha ah.

| Maya | Magaca alaabta | Quudinta adkaanta (g/l) | Dib-u-dejinta biyaha (MPa) | Dhumucda keegga (mm) | Qoyaan keega (%) | Awoodda kg/m2.h |

| 1 | 4A-zeolite | 150-295 | 1.4 | 35 | 19 ~ 22 | 190-200 |

| 2 | Sulfuret | ≈50 | 1.2 | 30 | 30 | 120 |

| 3 | Hogaamin | ≈50 | 1.2 | 30 | 15 ~ 20 | 35 |

| 4 | Dharka naxaasta ah | 600 | 1.6 | 40 | 8 ~ 9 | 310 |

| 5 | Sulfate biyaha wasakhda ah | 80 | 1.6 | 45 | 28-35 | 120 ~ 175 |

| 6 | Calcination dabo dahab ah | 300 | 1.6 | 35 | 14 ~ 18 | 300 ~ 340 |

| 7 | Superfine aluminium hydroxide | 15 ~ 20% | 1.6 | 20 | 29.5-32 | 65 |

| 8 | Cu-Ni xoojinta | 66.7 | 1.6 | 30 | 9.78 | 257 |

| 9 | Isku-duubnida maarta | 45-50 | 1.6 | 35 | 7.6 | 360 |

| 10 | Ni fiirsashada | 45-50 | 1.6 | 30 | 8 | 300 ~ 400 |

| 11 | Tantalum-niobium ayaa dhalaalaysa | 1.6 | 20 ~ 25 | 200 | ||

| 12 | Dhuxusha dhuxusha | 30 ~ 35% | 1.6 | 30 | 16 ilaa 17 | 300 |

| 14 | Dabo dahab ah sabbeynta ka dib | 20 ~ 30% | 1.6 | 35 | 12 ~ 18 | 300 |

| 15 | Mannitol | 1.5 | 12 | 35 | ||

| 16 | Zinc oxide budada | 57% | 1.6 | 18 | 20 | 90 |

| 17 | Haraaga zinc oxide oo sii daaya | 50% | 1.6 | 10 | 18 ~ 20 | 70 |

| 18 | Sulfur xoogga saaray | 10% | 1.6 | 20 | 25 ~ 35 | 200 |

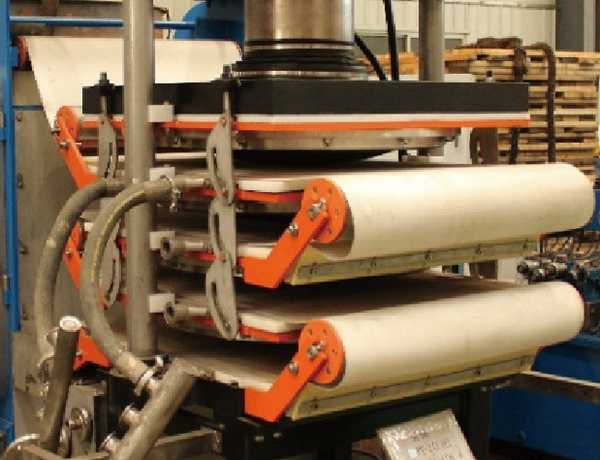

Qaab dhismeedka Qalabka

Qaab dhismeedka Kooxda Plate

Sawirro Soo Saar

Qaybaha ugu muhiimsan

Isticmaalka Goobta