Sistimi ea ho omisa ea Sludge / Coal Slime

Sistimi ea ho omisa ea Sludge / Coal Slime

Tlhaloso ea Tsamaiso

Mokhoa oa khale oa ho lahla moiteli oa mehlape ke ho rekisoa e le moiteli oa mapolasi ka theko e tlase 'me o sebelisoe ka kotloloho joalo ka monontša oa temo, boleng ba ona moruong ha se ho hlahlojoa le ho sebelisoa ka botlalo.Ha e le hantle, tsena ke mehloli ea bohlokoa ea furu le manyolo, haeba e ka ntlafatsoa le ho sebelisoa, e tla ba le bohlokoa bo boholo ho tlhahiso ea manyolo a manyolo, ho nts'etsopele ea indasteri ea ho lema le ea ho ikatisa, ho khothalletsa tlhahiso ea temo le chelete, ho boloka matla le Lijo tse tala tse se nang tšilafalo, nts'etsopele ea temo e tala, ho sireletsa tikoloho le bophelo bo botle ba batho.

Ka ntlafatso e tsoelang pele ea tlhokomeliso ea batho mabapi le ts'ireletso ea tikoloho, le theknoloji ea ho omisa seretse le eona e nts'etsopele e potlakileng, boqapi bo sa feleng le ntlafatso le tsona li etsahala likarolong tsa ho boloka matla, polokeho, ts'epo, ts'ebetso.Sistimi ea rona ea ho omisa seretse e tlo fokotsa bongata ba metsi a seretse se sentsoeng ho tloha ho 80 + 10% ho isa ho 20 + 10%.Melemo ea tsamaiso ea rona ke e latelang:

1. Boima ba sludge e omisitsoeng bo ka fokotsoa ho 1/4 boima ba lintho tse metsi pele li omisoa, tse fokotsang haholo khatello ea tikoloho le moruo oa khoebo;

2. Mocheso o kenang moeeng oa se omisang ke 600-800 ℃, 'me o ka sebelisoa bakeng sa sterilization, deodorant, joalo-joalo ka nako e le' ngoe ea ho omisa, 'me ho tla fanoa ka tiiso e tšepahalang bakeng sa tšebeliso ea lihlahisoa tse omisitsoeng;

3. Lihlahisoa tse omisitsoeng li ka sebelisoa e le lijo, manyolo, mafura, thepa ea mohaho, lisebelisoa tsa ho ntša litšepe tse boima, ho lemoha tšebeliso ea litšila.

Letlapa le tšetsoeng metsi le tla isoa hloohong e fepang ea se omisang ka sekoaelo sa screw ka mor'a hore le hasane, ebe le tla romelloa ka hare ho se omisang ka sesebelisoa se se nang matla sa spiral sealing (theknoloji ea patent ea k'hamphani ea rona), le ho feta har'a tse 'maloa. libaka tse latelang tsa ho sebetsa ka mor'a ho kena ka har'a dryer:

1. Sebaka sa lintho tse etellang pele

Seretse se tla kopana le mocheso o phahameng oa khatello e mpe ea moea ka mor'a ho kena sebakeng sena 'me metsi a mangata a tla fetoha mouoane ka potlako,' me seretse se ke ke sa etsoa hore e be lintho tse khomarelang tlas'a ho sisinyeha ha poleiti e kholo ea tataiso.

2. Sebaka sa ho hloekisa

Lesela la lintho tse bonahalang le tla thehoa ha seretse se phahamisoa sebakeng sena, 'me se tla etsa hore thepa e khomarele leboteng la cylinder ha e ntse e oela fatše,' me sesebelisoa sa ho hloekisa se kentsoe sebakeng sena (Lifting style stirring plate, X type second. nako e susumetsang poleiti, ketane e nang le tšusumetso, poleiti e nang le tšusumetso), sludge e ka tlosoa ka potlako leboteng la cylinder ka sesebelisoa sa ho hloekisa, 'me sesebelisoa sa ho hloekisa se ka boela sa senya lisebelisoa tse kopantsoeng hammoho, e le ho eketsa sebaka sa phapanyetsano ea mocheso, ho eketsa. nako ea ho fapanyetsana mocheso, qoba ho hlahisa phenomenon ea moea kotopo, ntlafatsa lebelo la ho omisa;

3. Sebaka sa poleiti ea ho phahamisa e sekametseng

Sebaka sena ke sebaka sa ho omisa mocheso o tlaase, slime ea sebaka sena e le mongobo o tlaase le boemo bo hlephileng, 'me ha ho na ntho ea ho khomarela sebakeng sena, lihlahisoa tse felileng li finyella litlhoko tsa mongobo ka mor'a phapanyetsano ea mocheso, ebe li kena qetellong. sebaka sa ho tsoa;

4. Sebaka sa ho qhala

Ha ho na lipoleiti tse sisinyehang sebakeng sena sa silinda ea se omisang, 'me thepa e tla be e theohetse boema-kepeng ba ho ntša metsi.

The sludge butle-butle e ba hlephileng ka mor'a ho omisa, 'me a lokolloe ho tloha qetellong ea ho ntša, ebe o romeloa sebakeng se khethiloeng ke sesebelisoa sa ho tsamaisa,' me lerōle le letle le huloang hammoho le khase ea mohatla le bokelloa ke mokelli oa lerōle.

Moea o chesang o kena ka har'a mochini o omisang ho tloha pheletsong ea phepelo, 'me mocheso o fokotseha butle butle ka nako e ts'oanang ea phetisetso ea mocheso oa thepa,' me mouoane oa metsi o ntšoa ka tlas'a ho huloa ha fan e kentsoeng, ebe o kenngoa moeeng ka mor'a ho sebetsa. .

Kopo ka mor'a ho omisa

Ho sebelisoa tšepe e boima

Nakong ea ts'ebetso ea ho hloekisa metsi a litšila tsa semela sa smelting, fektheri ea khatiso ea boto ea potoloho, lifeme tsa electroplating le likhoebo tse ling, 'me sludge e hlahisoang e na le lisebelisoa tse ngata tse boima (koporo, nickel, khauta, silevera, joalo-joalo).Ho tla ba le tšilafalo e kholo haeba likarolo tsena tsa tšepe li ntšoa, empa melemo e mengata ea moruo e ka finyelloa ka mor'a ho ntšoa le ho hloekisoa.

Ho hlahisa matla a ho chesoa

Khalo ea lik'hilojule ea sludge e omisitsoeng e tsoa ho 1300 ho ea ho 1500 lik'hilojule, lithane tse tharo tsa sludge tse omeletseng li ka lekana le tone e le 'ngoe ea mashala a 4500 kcal, a ka chesoang ka sebōping se kopantsoeng le mashala.

Lintho tsa ho haha

Concrete aggregate, samente admixture le tlhahiso ea katoa encaustic setene, permeable setene, faeba boto, ho etsa litene ka ho phaella ka letsopa, matla a eona a lekana le litene tse khubelu tse tloaelehileng, 'me e na le mocheso o itseng, ha o ntse o lelekoa. setene, ho tuka ho itlelang feela ho ka finyelloa ho eketsa mocheso.

Manyolo a tlhaho

Seretse se omisitsoeng se tla bela ho ba monontša oa boleng bo holimo ka mor'a ho kenya moiteli oa likhomo, ka katleho e ntle ea manyolo, tšebeliso e sireletsehileng le e bonolo, le ho thibela maloetse le ho khothalletsa kholo, e ka boela ea nontša mobu.

Tšebeliso ea temo

Ho na le dikahare tse hodimo tsa N, P le K ka hara seretse, mme e hodimo haholo ho feta ya moitedi wa kolobe, moitedi wa dikgomo le moitedi wa dikgoho, mme ho na le dikahare tse ngata tsa organic compound.E ka sebelisoa e le manyolo a temo ka mor'a hore ho lokisoe mokhoa oa ho omisa seretse, 'me e ka etsa mobu oa boleng ka ho lekanya lithōle.

Tekheniki Parameters

| Mohlala | Bophara ba silinda(mm) | Bolelele ba silinda(mm) | Bophahamo ba cylinder(m3) | Lebelo la cylinder rotary (r/min) | Matla(kW) | Boima (t) |

| VS0.6x5.8 | 600 | 5800 | 1.7 | 1-8 | 3 | 2.9 |

| VS0.8x8 | 800 | 8000 | 4 | 1-8 | 4 | 3.5 |

| VS1x10 | 1000 | 10000 | 7.9 | 1-8 | 5.5 | 6.8 |

| VS1.2x5.8 | 1200 | 5800 | 6.8 | 1-6 | 5.5 | 6.7 |

| VS1.2x8 | 1200 | 8000 | 9 | 1-6 | 5.5 | 8.5 |

| VS1.2x10 | 1200 | 10000 | 11 | 1-6 | 7.5 | 10.7 |

| VS1.2x11.8 | 1200 | 11800 | 13 | 1-6 | 7.5 | 12.3 |

| VS1.5x8 | 1500 | 8000 | 14 | 1-5 | 11 | 14.8 |

| VS1.5x10 | 1500 | 10000 | 17.7 | 1-5 | 11 | 16 |

| VS1.5x11.8 | 1500 | 11800 | 21 | 1-5 | 15 | 17.5 |

| VS1.5x15 | 1500 | 15000 | 26.5 | 1-5 | 15 | 19.2 |

| VS1.8x10 | 1800 | 10000 | 25.5 | 1-5 | 15 | 18.1 |

| VS1.8x11.8 | 1800 | 11800 | 30 | 1-5 | 18.5 | 20.7 |

| VS1.8x15 | 1800 | 15000 | 38 | 1-5 | 18.5 | 26.3 |

| VS1.8x18 | 1800 | 18000 | 45.8 | 1-5 | 22 | 31.2 |

| VS2x11.8 | 2000 | 11800 | 37 | 1-4 | 18.5 | 28.2 |

| VS2x15 | 2000 | 15000 | 47 | 1-4 | 22 | 33.2 |

| VS2x18 | 2000 | 18000 | 56.5 | 1-4 | 22 | 39.7 |

| VS2x20 | 2000 | 20000 | 62.8 | 1-4 | 22 | 44.9 |

| VS2.2x11.8 | 2200 | 11800 | 44.8 | 1-4 | 22 | 30.5 |

| VS2.2x15 | 2200 | 15000 | 53 | 1-4 | 30 | 36.2 |

| VS2.2x18 | 2200 | 18000 | 68 | 1-4 | 30 | 43.3 |

| VS2.2x20 | 2200 | 20000 | 76 | 1-4 | 30 | 48.8 |

| VS2.4x15 | 2400 | 15000 | 68 | 1-4 | 30 | 43.7 |

| VS2.4x18 | 2400 | 18000 | 81 | 1-4 | 37 | 53 |

| VS2.4x20 | 2400 | 20000 | 91 | 1-4 | 37 | 60.5 |

| VS2.4x23.6 | 2400 | 23600 | 109 | 1-4 | 45 | 69.8 |

| VS2.8x18 | 2800 | 18000 | 111 | 1-3 | 45 | 62 |

| VS2.8x20 | 2800 | 20000 | 123 | 1-3 | 55 | 65 |

| VS2.8x23.6 | 2800 | 23600 | 148 | 1-3 | 55 | 70 |

| VS2.8x28 | 2800 | 28000 | 172 | 1-3 | 75 | 75 |

| VS3x20 | 3000 | 20000 | 141 | 1-3 | 55 | 75 |

| VS3x23.6 | 3000 | 23600 | 170 | 1-3 | 75 | 85 |

| VS3x28 | 3000 | 28000 | 198 | 1-3 | 90 | 91 |

| VS3.2x23.6 | 3200 | 23600 | 193 | 1-3 | 90 | 112 |

| VS3.2x32 | 3200 | 32000 | 257 | 1-3 | 110 | 129 |

| VS3.6x36 | 3600 | 36000 | 366 | 1-3 | 132 | 164 |

| VS3.8x36 | 3800 | 36000 | 408 | 1-3 | 160 | 187 |

| VS4x36 | 4000 | 36000 | 452 | 1-3 | 160 | 195 |

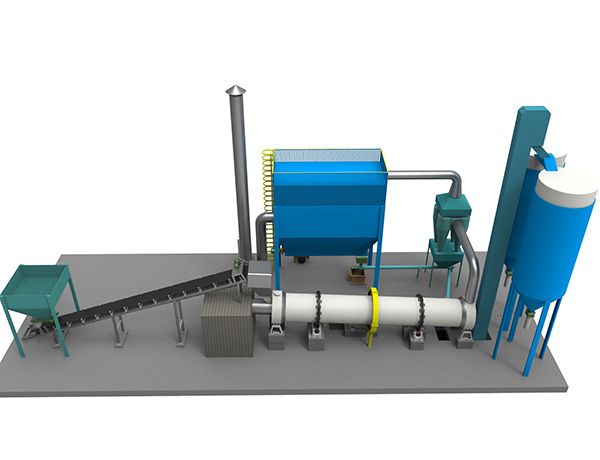

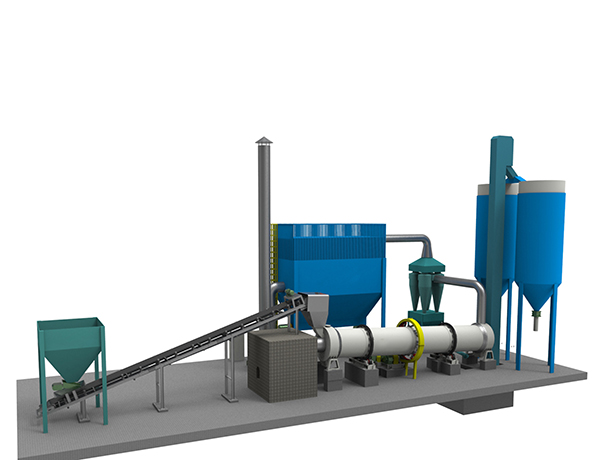

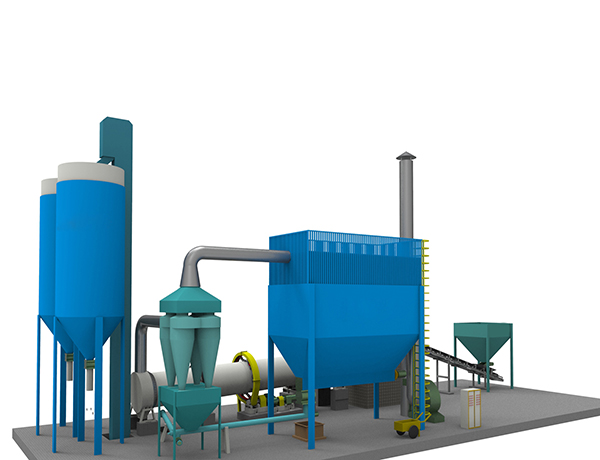

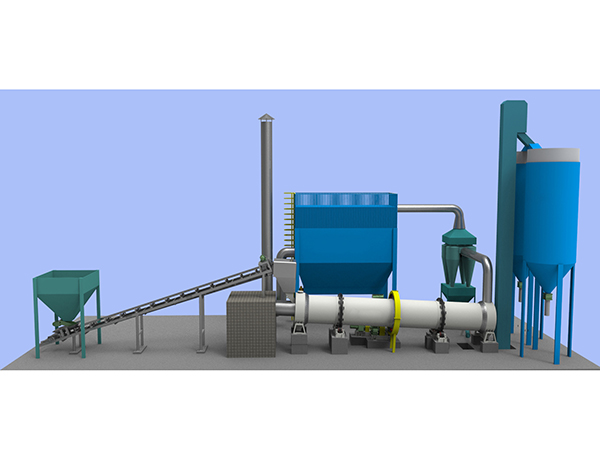

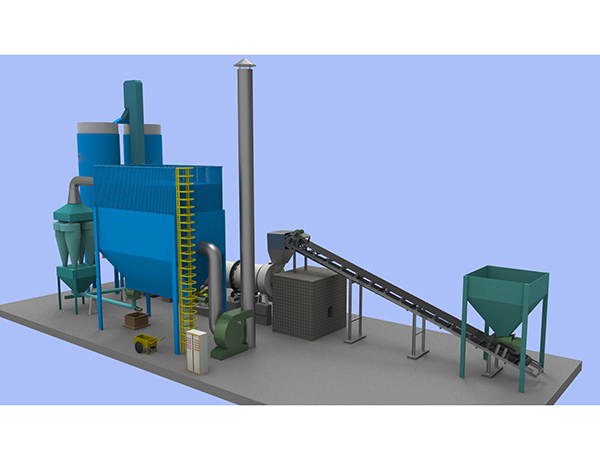

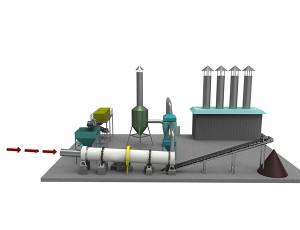

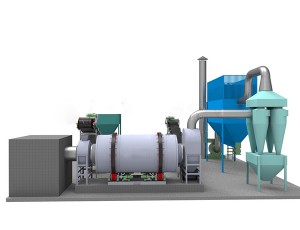

Litšoantšo tsa libaka tse sebetsang