VSPF Stacked Filter Press

VSPF Stacked Filter Press

Lisebelisoa

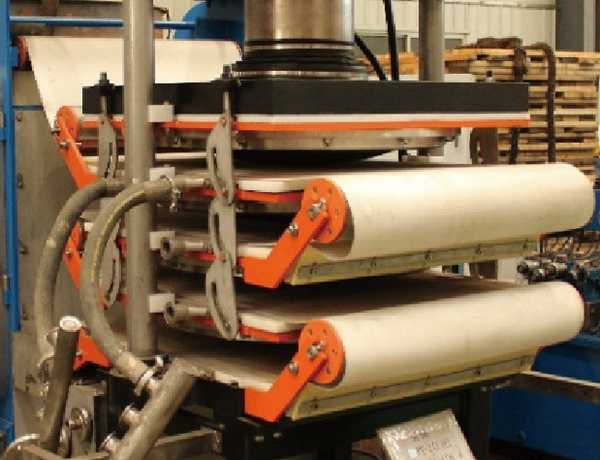

sebelisa sebopeho se bokeletsoeng bakeng sa lipoleiti, sebelisa sesebelisoa sa tataiso se thusang ho etsa hore ts'ebetso e be e tsitsitseng haholoanyane.

● Kopanya ho sefa, extrusion, ho hlatsoa, ho omisa moea, ho ntša likuku le ho hlatsoa masela hammoho.

● Khatello ea extrusion ho fihlela ho 1.6MPa, e sebelisoa haholo tšimong e nang le litlhoko tse fapaneng tsa mongobo oa kaka.

● 4.sebelisa tsamaiso ea ho laola li-hydraulic drive, etsa hore ts'ebetso e tsitse le ka matla a fokolang a matla.

● Ho kopanya PLC, HMI le tsamaiso ea lisebelisoa tsa lisebelisoa joalo-joalo bohlale hammoho, e etsa hore sefe e sebetse hantle le ho ba bonolo.

● Sebelisa sesebelisoa sa ho hloekisa metsi ka khatello e phahameng ho etsa hore ho hlatsuoa ha masela ho atlehe haholoanyane.

● Moralo o nang le kamore e chitja, sebopeho se utloahalang haholoanyane, katleho e hlahella haholoanyane.

Molao-motheo oa Ts'ebetso

1, Filtering: ha lipoleiti sehlopha koaloa, pompa slurry ho sefa, sebelisa hose ajoa ho fepa slurry ho e 'ngoe le e 'ngoe slurry kamoreng, le filtrate feta ka lesela ho filtrate foreime le ho qhala ka ntle, tiileng theha kaka holim'a lesela holim'a lesela.

2, Extrusion: metsi a khatello e phahameng a feptjoang ka phaposing e kaholimo ea rabara ea diaphragm, etsa hore diaphragm e atolohe le ho ntša kuku, 'me mokelikeli o tla tsoa ka har'a kuku.

3, Ho hlatsoa likuku: ho hlatsoa metsi ka phaposing ea slurry ka sekoaelo sa hose holim'a kaka ka ho feletseng, tlas'a khatello, metsi a hlatsoang a tšela kaka le lesela ho tsoa.

4, Ho omisa moea: moea o hatelletsoeng ka ho fepa hose ka phaposing e seretse le ho hatella diaphragm ea rabara, ho etsa hore metsi a khatello e phahameng ka har'a diaphragm ea rabara a tsoe, 'me moea o hatelitsoeng o fete ka kuku ebe o ntša metsi ho fokotsa mongobo oa kuku. boemo bo tlase.

5, Cake discharge: ha o qetile tshebetso ea ho omisa moea, bula sehlopha sa lipoleiti, tsamaiso ea koloi e etsa hore lesela le mathe le ho ntša kuku ka mahlakoreng a mabeli a filthara ka nako e le 'ngoe.

Tlhokomeliso: Ka kopo ho latela boemo ba 'nete ba ho sebelisa ho lokisa linako tsa extrusion le air- drying process.

Setšoantšo sa Phallo ea Ts'ebetso

Letoto la Lisebelisoa

Tlhaloso ea Setsebi

| Mohlala/VSPFⅠ | VSPFⅠ-1 | VSPFⅠ-2 | VSPFⅠ-3 |

| Sefa sebaka/m2 | 1 | 2 | 3 |

| Boholo ba poleiti/mm | 0.5m2/lera | ||

| Plate qty/layer | 2 | 4 | 6 |

| Bolelele/m | 2.5 | ||

| Bophara/m | 1.5 | ||

| Bophahamo/m | 2 | 2.2 | 2.5 |

| Boima/T | 8 | 9 | 10 |

| Matla a seteishene sa Hydraulic/KW | 7.5 | ||

| Hlooho ea pompo ea extrusion/m | 167 | ||

| Phallo ea pompo ea extrusion m3/h | 8 | ||

| Matla a pompo ea extrusion/KW | 7.5 | ||

Boitsebiso ba Lisebelisoa tsa Thuso

| Ho hlatsoa lipeipi hlooho/m | 70 | ||

| Pompo ea ho hlatsoa liphaephe e phalla m3/h | 10 | ||

| Ho hlatsoa masela pompo hlooho/m | 70 | ||

| Pompo ea ho hlatsoa masela e phalla m3/h | 10 | ||

| Hlooho/m | 70 | ||

| Pompo e fepelang seretse e phallang m3/h | Ho ea ka slurry ya data ho khetha | ||

| Khatello ea ho omisa moea/Mpa | 0.8 | ||

| Phallo ea moea ea compressor bakeng sa ho omisa moea m3/min | 0.5 | 1 | 1.5 |

| Bophahamo ba tanka ea ho omisa moea/m3 | 1 | 2 | 3 |

| Khatello ea moea bakeng sa lisebelisoa/Mpa | 0.7 | ||

| Phallo ea moea ea compressor bakeng sa lisebelisoa tsa m3 / min | 0.3 | ||

| Liletsa bophahamo ba tanka ea moea / m3 | 0.5 | ||

| Tlhokomeliso: boholo ba kemiso ea lisebelisoa ke boholo ba mantlha, empa ha se boholo ba lintlha, ka hona, boholo bona bakeng sa litšupiso feela.Lintho tse fapaneng tsa poleiti, filthara e tla ba le bophahamo le boima bo fapaneng.Lintlha tsa lisebelisoa tse thusang bakeng sa litšupiso feela, li tla fetoha ka ts'ebetso ea filthara ka mokhoa o fapaneng. | |||

Tlhaloso ea Setsebi

| Mohlala | VSPFⅡ-3 | VSPFⅡ-6 | VSPFⅡ-9 | VSPFⅡ-12 | VSPFⅡ-15 | VSPFⅡ-18 | VSPFⅡ-21 | VSPFⅡ-24 |

| filthara sebaka/m2 | 3 | 6 | 9 | 12 | 15 | 18 | 21 | 24 |

| boholo ba poleiti/mm | 1.5m2 / lera | |||||||

| plate Qty/ layer | 2 | 4 | 6 | 8 | 10 | 12 | 14 | 16 |

| bolelele/m | 3.7 | |||||||

| bophara/m | 4.1 | |||||||

| bophahamo/m | 2.6 | 2.8 | 3.2 | 3.7 | 4.2 | 4.6 | 5.1 | 5.5 |

| boima/T | 12 | 13 | 14 | 15 | 16 | 17 | 18 | 19 |

| hydraulic station power/KW | 11 | |||||||

| Hlooho ea pompo ea extrusion/m | 28 | |||||||

| Phallo ea pompo ea extrusion m3/h | 136 Tlhokomeliso: haeba khatello ea extrusion e feta 1.3MPa, data ena ke 164 | |||||||

| Matla a pompo ea extrusion/KW | 11 Tlhokomeliso: haeba khatello ea extrusion e feta 1.3MPa, data ena ke 15 | |||||||

Boitsebiso ba Lisebelisoa tsa Thuso

| Hlooho ea pompo ea ho hlatsoa lipeipi /m | 68 | |||||||

| Phallo ea pompo ea ho hlatsoa liphaephe m3/h | 20 | |||||||

| Ho hlatsoa masela pompo hlooho/m | 70 | |||||||

| Phallo ea pompo ea ho hlatsoa masela m3/h | 12 | |||||||

| Hlooho/m | 70 | |||||||

| Phallo ea pompo e fepelang seretse m3/h | Ho ea ka slurry ya data ho khetha | |||||||

| Khatello ea ho omisa moea/Mpa | 0.8 | |||||||

| Air kompressor phallo bakeng sa ho omisa moea m3/min | Ho ea ka slurry ya data ho khetha | |||||||

| Bophahamo ba tanka ea ho omisa moea/m3 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 |

| Khatello ea moea bakeng sa lisebelisoa/Mpa | 0.7 | |||||||

| Air kompressor phallo bakeng sa lisebelisoa m3/min | 0.5 | |||||||

| Liletsa bophahamo ba tanka ea moea / m3 | 1 | |||||||

| Tlhokomeliso: boholo ba kemiso ea lisebelisoa ke boholo ba mantlha, empa ha se boholo ba lintlha, ka hona, boholo bona bakeng sa litšupiso feela.Lintho tse fapaneng tsa poleiti, filthara e tla ba le bophahamo le boima bo fapaneng.Lintlha tsa lisebelisoa tse thusang bakeng sa litšupiso feela, li tla fetoha ka ts'ebetso ea filthara ka mokhoa o fapaneng. | ||||||||

Tlhaloso ea Setsebi

| Mohlala oa VSPFⅢ | VSPFⅢ-18 | VSPFⅢ-24 | VSPFⅢ-30 | VSPFⅢ-36 | VSPFⅢ-42 | VSPFⅢ-48 | VSPFⅢ-54 | VSPFⅢ-60 | VSPFⅢ-66 |

| filthara sebaka/m2 | 18 | 24 | 30 | 36 | 42 | 48 | 54 | 60 | 66 |

| boholo ba poleiti/mm | 3.0m2/lera | ||||||||

| plate Qty/ layer | 6 | 8 | 10 | 12 | 14 | 16 | 18 | 20 | 22 |

| bolelele/m | 5.1 | ||||||||

| bophara/m | 5.5 | ||||||||

| bophahamo/m | 4.3 | 4.5 | 4.9 | 5.4 | 5.8 | 6.3 | 6.8 | 7.2 | 7.7 |

| boima/T | 31 | 33 | 35 | 37 | 39 | 41 | 43 | 45 | 47 |

| hydraulic station powerKW | 22 | ||||||||

| Hlooho ea pompo ea extrusion/m | 40 | 55 | |||||||

| Phallo ea pompo ea extrusion m3/h | 136 Tlhokomeliso: haeba khatello ea extrusion e feta 1.3MPa, data ena ke 162 | 135 Tlhokomeliso: haeba khatello ea extrusion e feta 1.3MPa, data ena ke 166 | |||||||

| Matla a pompo ea extrusion/KW | 15 Tlhokomeliso: haeba khatello ea extrusion e feta 1.3MPa, data ena ke 18.5 | 22 Tlhokomeliso: haeba khatello ea extrusion e feta 1.3MPa, data ena ke 30 | |||||||

Boitsebiso ba Lisebelisoa tsa Thuso

| Ho hlatsoa lipeipi hlooho/m | 65 | ||||||||

| Pompo ea ho hlatsoa liphaephe e phalla m3/h | 26 | ||||||||

| Ho hlatsoa masela pompo hlooho/m | 70 | ||||||||

| Pompo ea ho hlatsoa masela e phalla m3/h | 16 | ||||||||

| Hlooho/m | 70 | ||||||||

| Pompo e fepelang seretse e phallang m3/h | Ho ea ka slurry ya data ho khetha | ||||||||

| Khatello ea ho omisa moea/Mpa | 0.8 | ||||||||

| Phallo ea moea ea compressor bakeng sa ho omisa moea m3/min | Ho ea ka slurry ya data ho khetha | ||||||||

| Bophahamo ba tanka ea ho omisa moea/m3 | 8 | 10 | 10 | 12 | 12 | 15 | 15 | 20 | 20 |

| Khatello ea moea bakeng sa lisebelisoa/Mpa | 0.7 | ||||||||

| Phallo ea moea ea compressor bakeng sa lisebelisoa tsa m3 / min | 0.5 | ||||||||

| Liletsa bophahamo ba tanka ea moea / m3 | 1 | ||||||||

| Tlhokomeliso: boholo ba kemiso ea lisebelisoa ke boholo ba mantlha, empa ha se boholo ba lintlha, ka hona, boholo bona bakeng sa litšupiso feela.Lintho tse fapaneng tsa poleiti, filthara e tla ba le bophahamo le boima bo fapaneng.Lintlha tsa lisebelisoa tse thusang bakeng sa litšupiso feela, li tla fetoha ka ts'ebetso ea filthara ka mokhoa o fapaneng. | |||||||||

Tlhaloso ea Setsebi

| Mohlala oa VSPFⅣ | VSPFⅣ-60 | VSPFⅣ-72 | VSPFⅣ-84 | VSPFⅣ-96 | VSPFⅣ-108 | VSPFⅣ-120 | VSPFⅣ-132 | VSPFⅣ-144 | VSPFⅣ-156 | VSPFⅣ-168 |

| Sefa sebaka/m2 | 60 | 72 | 84 | 96 | 108 | 120 | 132 | 144 | 156 | 168 |

| Boholo ba poleiti/mm | 6m2/lera | |||||||||

| Plate Qty/lera | 10 | 12 | 14 | 16 | 18 | 20 | 22 | 24 | 26 | 28 |

| Bolelele/m | 7.1 | |||||||||

| Bophara/m | 5.5 | |||||||||

| Bophahamo/m | 5.4 | 5.8 | 6.2 | 6.6 | 6.9 | 7.2 | 7.6 | 7.9 | 8.3 | 8.6 |

| Boima/T | 92 | 96 | 100 | 104 | 108 | 112 | 116 | 120 | 124 | 128 |

| Matla a seteishene sa Hydraulic/KW | 30 | 37 | ||||||||

| Hlooho ea pompo ea extrusion/m | 110 | 150 | ||||||||

| Phallo ea pompo ea extrusion m3/h | 126 Tlhokomeliso: haeba khatello ea extrusion e feta 1.3MPa, data ena ke 168 | 128 Tlhokomeliso: haeba khatello ea extrusion e feta 1.3MPa, data ena ke 162.5 | ||||||||

| Matla a pompo ea extrusion/KW | 37 Tlhokomeliso: haeba khatello ea extrusion e feta 1.3MPa, data ena ke 45 | 55 Tlhokomeliso: > 1.3MPa, data ena ke 75 | ||||||||

Boitsebiso ba Lisebelisoa tsa Thuso

| Ho hlatsoa lipeipi hlooho/m | 72 | |||||||||

| Phallo ea pompo ea ho hlatsoa liphaephe m3/h | 36 | |||||||||

| Ho hlatsoa masela pompo hlooho/m | 70 | |||||||||

| Phallo ea pompo ea ho hlatsoa masela m3/h | 20 | |||||||||

| Hlooho/m | 70 | |||||||||

| Phallo ea pompo e fepelang seretse m3/h | Ho ea ka slurry ya data ho khetha | |||||||||

| Khatello ea ho omisa moea/Mpa | 0.8 | |||||||||

| Air kompressor phallo bakeng sa ho omisa moea m3/min | Ho ea ka slurry ya data ho khetha | |||||||||

| Bophahamo ba tanka ea ho omisa moea/m3 | 20 | 20 | 25 | 30 | 35 | 35 | 40 | 40 | 45 | 45 |

| Khatello ea moea bakeng sa lisebelisoa/Mpa | 0.7 | |||||||||

| Air kompressor phallo bakeng sa lisebelisoa m3/min | 1 | |||||||||

| Liletsa bophahamo ba tanka ea moea / m3 | 2 | |||||||||

| Tlhokomeliso: boholo ba kemiso ea lisebelisoa ke boholo ba mantlha, empa ha se boholo ba lintlha, ka hona, boholo bona bakeng sa litšupiso feela.Lintho tse fapaneng tsa poleiti, filthara e tla ba le bophahamo le boima bo fapaneng.Lintlha tsa lisebelisoa tse thusang bakeng sa litšupiso feela, li tla fetoha ka ts'ebetso ea filthara ka mokhoa o fapaneng. | ||||||||||

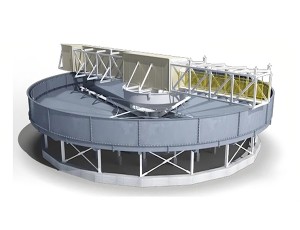

Libaka tsa Kopo

E sebelisoa haholo ho likhoerekhoere tsa litoropo, khatiso ea masela le ho daea, electroplate, ho etsa pampiri, letlalo, ho riteloa, ho lokisa lijo, ho hlatsoa mashala, indasteri ea petrochemical, k'hemistri, metallurgy, karohano ea liminerale, k'hemistri, indasteri ea ceramic dewatering le joalo-joalo, hape e sebelisoa ho tlhahiso ea indasteri karohano e tiileng-metsi kapa ts'ebetso ea leaching ea metsi.

| Che. | Lebitso la thepa | Matla a fepa (g/l) | Extrusion water ressure (MPa) | Botenya ba kuku (mm) | Mongobo oa kuku (%) | Bokhoni ba lik'hilograma/m2.h |

| 1 | 4A-zeolite | 150-295 | 1.4 | 35 | 19-22 | 190-200 |

| 2 | Sebabole | ≈50 | 1.2 | 30 | 30 | 120 |

| 3 | Ketapele | ≈50 | 1.2 | 30 | 15-20 | 35 |

| 4 | Slag ea koporo | 600 | 1.6 | 40 | 8-9 | 310 |

| 5 | Sulfate ea metsi a litšila | 80 | 1.6 | 45 | 28-35 | 120-175 |

| 6 | Mehatla ea khauta ea calcination | 300 | 1.6 | 35 | 14-18 | 300-340 |

| 7 | Superfine aluminium hydroxide | 15-20% | 1.6 | 20 | 29.5-32 | 65 |

| 8 | Cu-Ni mahloriso | 66.7 | 1.6 | 30 | 9.78 | 257 |

| 9 | Khopolo ea koporo | 45-50 | 1.6 | 35 | 7.6 | 360 |

| 10 | Ke concentration | 45-50 | 1.6 | 30 | 8 | 300-400 |

| 11 | Monko oa Tantalum-niobium | 1.6 | Lilemo tse 20-25 | 200 | ||

| 12 | Seretse sa mashala | 30~35% | 1.6 | 30 | 16-17 | 300 |

| 14 | Mehatla ea khauta ka mor'a ho phaphamala | 20-30% | 1.6 | 35 | 12-18 | 300 |

| 15 | Mannitol | 1.5 | 12 | 35 | ||

| 16 | Zinc oxide phofo | 57% | 1.6 | 18 | 20 | 90 |

| 17 | Leaching masala a zinc oxide | 50% | 1.6 | 10 | 18-20 | 70 |

| 18 | Sulfur concentrate | 10% | 1.6 | 20 | Lilemo tse 25-35 | 200 |

Sebopeho sa Thepa

Sebopeho sa Sehlopha sa Plate

Ho Etsa Litšoantšo

Likarolo tse ka Sehloohong

Ho sebelisa Site