Tanuri ya Rotary kwa Kiwanda cha Uzalishaji Saruji

Tanuri ya Rotary kwa Kiwanda cha Uzalishaji Saruji

Utangulizi

Tanuri ya Saruji hutumika zaidi kukalisha klinka na ina aina kavu na aina ya mvua.

Tanuri ya metallurgiska na kemikali hutumiwa hasa kwa ukalisishaji duni wa sumaku wa madini ya chuma, ukalisishaji vioksidishaji wa ore ya chromium, ore ya ferronickel;calcination ya high alumini ore bauxite katika kiwanda refractory nyenzo na hidroksidi alumini, klinka, alumini hidroksidi calcination katika kupanda alumini;uhesabuji wa ore ya chrome na unga wa chrome kwenye mmea wa kemikali, nk.

Tanuru ya chokaa inayotumika hutumika kukokotoa chokaa hai na dolomite katika kiwanda cha kutengeneza chuma na kiwanda cha aloi ya chuma.

Kanuni ya Kufanya Kazi

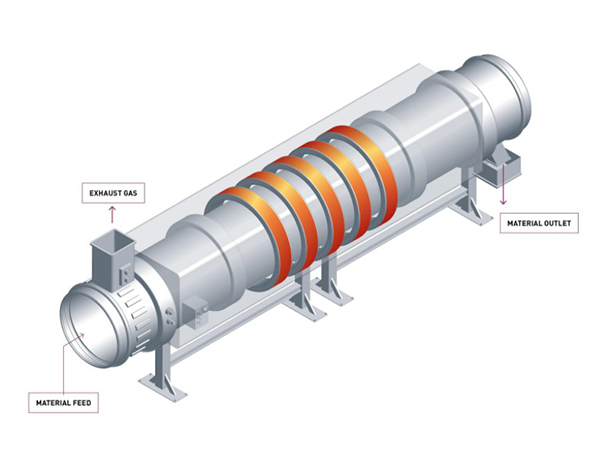

Nyenzo hulishwa ndani ya tanuru ingawa mwisho wa tanuru (upande wa juu wa silinda).Kwa sababu silinda ina mwelekeo na inazunguka polepole, nyenzo husogea pamoja na duara na mwelekeo wa axial (kutoka upande wa juu hadi chini).Baada ya kupitia mabadiliko ya kimwili na kemikali, nyenzo huingia kwenye mashine ya kupoeza kupitia kifuniko cha kichwa cha tanuru baada ya kumaliza ukalisishaji.Mafuta hutiwa ndani ya kichwa cha tanuru kupitia kichwa cha tanuru, na gesi ya kutolea nje itatoka mwishoni mwa tanuru baada ya kubadilishana joto na nyenzo.

Vigezo vya Kiufundi

| Mfano | Vigezo vya tanuru | Uwezo(t/d) | Kasi ya Mzunguko(r/min) | Nguvu (kW) | Uzito(t) | ||

| Kipenyo(m) | Urefu(m) | Mteremko(%) | |||||

| VS1.4x33 | 1.4 | 33 | 3 | 26 | 0.39-3.96 | 18.5 | 48 |

| VS1.6x36 | 1.6 | 36 | 4 | 37 | 0.26-2.63 | 22 | 52 |

| VS1.8x45 | 1.8 | 45 | 4 | 52 | 0.16-1.62 | 30 | 78 |

| VS1.9x39 | 1.9 | 39 | 4 | 56 | 0.29-2.93 | 30 | 78 |

| VS2.0x40 | 2 | 40 | 3 | 78 | 0.23-2.26 | 37 | 119 |

| VS2.2x45 | 2.2 | 45 | 3.5 | 106 | 0.21-2.44 | 45 | 128 |

| VS2.5x40 | 2.5 | 40 | 3.5 | 180 | 0.44-2.44 | 55 | 150 |

| VS2.5x50 | 2.5 | 50 | 3 | 200 | 0.62-1.86 | 55 | 187 |

| VS2.5x54 | 2.5 | 54 | 3.5 | 204 | 0.48-1.45 | 55 | 196 |

| VS2.7x42 | 2.7 | 42 | 3.5 | 320 | 0.10-1.52 | 55 | 199 |

| VS2.8x44 | 2.8 | 44 | 3.5 | 400 | 0.437-2.18 | 55 | 202 |

| VS3.0x45 | 3 | 45 | 3.5 | 500 | 0.5-2.47 | 75 | 211 |

| VS3.0x48 | 3 | 48 | 3.5 | 700 | 0.6-3.48 | 100 | 237 |

| VS3.0x60 | 3 | 60 | 3.5 | 300 | 0.3-2 | 100 | 310 |

| VS3.2x50 | 3.2 | 50 | 4 | 1000 | 0.6-3 | 125 | 278 |

| VS3.3x52 | 3.3 | 52 | 3.5 | 1300 | 0.266-2.66 | 125 | 283 |

| VS3.5x54 | 3.5 | 54 | 3.5 | 1500 | 0.55-3.4 | 220 | 363 |

| VS3.6x70 | 3.6 | 70 | 3.5 | 1800 | 0.25-1.25 | 125 | 419 |

| VS4.0x56 | 4 | 56 | 4 | 2300 | 0.41-4.07 | 315 | 456 |

| VS4.0x60 | 4 | 60 | 3.5 | 2500 | 0.396-3.96 | 315 | 510 |

| VS4.2x60 | 4.2 | 60 | 4 | 2750 | 0.4-3.98 | 375 | 633 |

| VS4.3x60 | 4.3 | 60 | 3.5 | 3200 | 0.396-3.96 | 375 | 583 |

| VS4.5x66 | 4.5 | 66 | 3.5 | 4000 | 0.41-4.1 | 560 | 710 |

| VS4.7x74 | 4.7 | 74 | 4 | 4500 | 0.35-4 | 630 | 849 |

| VS4.8x74 | 4.8 | 74 | 4 | 5000 | 0.396-3.96 | 630 | 899 |