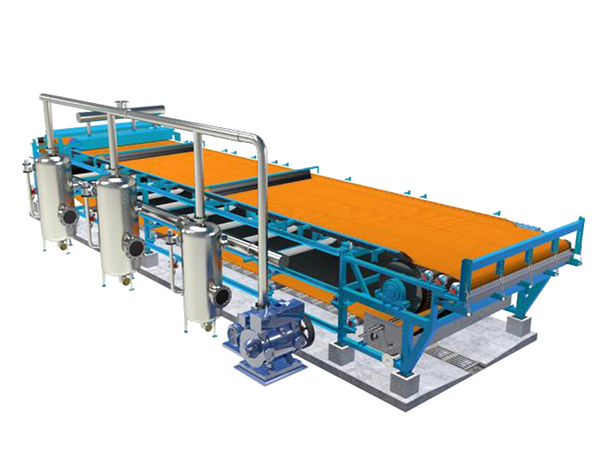

Isihluzi seBhanti ye-Du eHorizontal

Isihluzi seBhanti ye-Du eHorizontal

Umgaqo wokuSebenza

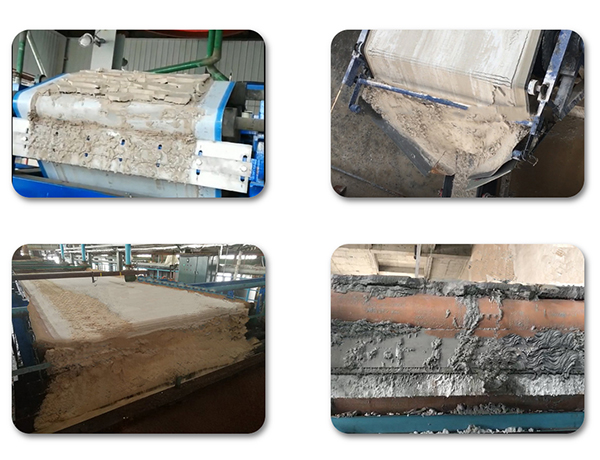

Esi sixhobo samkela igumbi lokucoca elisisigxina, ibhanti lerabha liqhutywa yibhokisi yegiya kwaye liqhuba ngokuqhubekayo kwigumbi lokucoca, ilaphu lihamba ngokuhambelanayo kwibhanti yerabha.Ibhanti le-friction kwi-slipway ye-vacuum yegumbi elenza isakhiwo sokutywinwa kwamanzi kunye nebhanti yerabha.Ukutya okudaka kwilaphu ngokutyibilikayo nangokulinganayo ngokutyisa ihopper.Xa igumbi lokucoca lidibanisa nenkqubo yokucoca, indawo yokuhluza kunye ne-vacuum suction iya kwenziwa kwibhanti yerabha, i-filtrate idlule kwilaphu kwaye igeleze kwi-grooves kunye nemingxunya yebhanti yerabha kwi-vacuum chamber, izinto eziqinileyo zenza ikhekhe kwi umphezulu welaphu.Ifiltrate kwigumbi lokufunxa ekhutshwe yitanki yokufunxa.Ukuhamba ngebhanti yerabha, ikhekhe lihamba kwindawo yokuhlamba ikhekhe kunye nendawo yokomisa ngokulandelelana, emva koko ungene kwindawo yokukhupha ikhekhe.Emva kokukhupha ikhekhe, ilaphu lihlanjwe ngenkqubo yokuhlamba kwaye ungene kumjikelo olandelayo wokucoca.

Iimbonakalo

● Uyilo lwemodyuli, indibano eguquguqukayo kunye nothutho olufanelekileyo luphunyezwa kwisakhiwo.Kwakhona, inokuhambisa zonke izixhobo ezidityanisiweyo emva kokuhlanganisana kunye novavanyo lokuqhuba.

● Ilaphu lokucoca kunye nebhanti yerabha esebenza ngokuhambelanayo isetyenziswe kwisihlunu, esinokugqitywa inkqubo yokutya okuqhubekayo, ukuhluza, ukuhlamba, ukomisa kunye nokuhlamba iingubo.

● Ulawulo olukude kunye nolawulo lwendawo lungatshintshwa ukuze kuphunyezwe imisebenzi engenziwanga.

● Kwinkxaso yebhanti yerabha, sinokusebenzisa i-roller, i-cushion yomoya, i-pallet kunye neebhanti ezininzi zokunciphisa ukunciphisa ukuxhatshazwa kunye nokwandisa ixesha lokuphila kwebhanti yerubha.

● Sebenzisa i-filtrate okanye amanzi acocekileyo ukuhlamba ikhekhe, kwaye uqokelele i-filtrate ngamacandelo.

● Sebenzisa amanzi anoxinzelelo oluphezulu ekuhlambeni amalaphu ukunyusa ifuthe lokuvuselela ilaphu kunye nexesha lokuphila.

● Iintlobo zokukhutshwa kwe-filtrate ziquka ukukhutshwa ngokuzenzekelayo, ukukhutshwa kwezinga eliphezulu kunye nokukhutshwa kokuncedisa.

● Isigqubuthelo segesi okanye iifestile ze-aluminiyam zeplastiki zinokuyilwa ukuba zivaleleke ngokungaphelelanga okanye zivalwe ngokupheleleyo ukwenzela ukugquma okungaphelelanga okanye ingqokelela esembindini yerhasi eguqukayo okanye umphunga wodaka.

Inkcazo yobuGcisa

| Indawo yokucoca | Ububanzi obusebenzayo | Ubude obusebenzayo | Ubude besakhelo | Isakhelo ububanzi | Isakhelo ukuphakama | Ubunzima | Vacuum ukusetyenziswa |

| 2 | 500 | 4000 | 8100 | 1100 | 2070 | 5.5 | 8 |

| 3 | 6000 | 10100 | 6 | 12 | |||

| 4 | 8000 | 12100 | 6.5 | 16 | |||

| 5 | 10000 | 14100 | 7 | 18 | |||

| 6 | 12000 | 16100 | 7.6 | 22 | |||

| 8 | 1000 | 8000 | 12100 | 1600 | 2070 | 8.8 | 25 |

| 10 | 10000 | 14100 | 9.6 | 28 | |||

| 12 | 12000 | 16100 | 10.4 | 30 | |||

| 14 | 14000 | 18100 | 11.1 | 33 | |||

| 10.4 | 1300 | 8000 | 12100 | 1900 | 2170 | 9.8 | 28 |

| 13 | 10000 | 14100 | 10.8 | 30 | |||

| 15.6 | 12000 | 16100 | 11.5 | 35 | |||

| 18.2 | 14000 | 18100 | 13.2 | 38 | |||

| 20.8 | 16000 | 20100 | 15.1 | 42 | |||

| 20 | 2000 | 10000 | 14100 | 2700 | 2170 | 14.2 | 40 |

| 24 | 12000 | 16100 | 17.8 | 48 | |||

| 28 | 14000 | 18100 | 20.2 | 52 | |||

| 32 | 16000 | 20100 | 23.6 | 65 | |||

| 20 | 2500 | 8000 | 12100 | 3200 | 2270 | 14.8 | 40 |

| 25 | 10000 | 14100 | 18.6 | 50 | |||

| 30 | 12000 | 16100 | 22.2 | 60 | |||

| 35 | 14000 | 18100 | 26 | 70 | |||

| 40 | 16000 | 20100 | 29.8 | 80 | |||

| 50 | 20000 | 24100 | 41 | 95 | |||

| 30 | 3000 | 10000 | 14100 | 3750 | 2270 | 22.8 | 60 |

| 36 | 12000 | 16100 | 27.5 | 72 | |||

| 42 | 14000 | 18100 | 32.5 | 85 | |||

| 54 | 18000 | 22100 | 45 | 105 | |||

| 60 | 20000 | 24100 | 50.5 | 120 | |||

| 48 | 4000 | 12000 | 16100 | 4800 | 2470 | 39.5 | 92 |

| 56 | 14000 | 18100 | 46.8 | 110 | |||

| 64 | 16000 | 20100 | 52.6 | 120 | |||

| 72 | 18000 | 22100 | 58.3 | 145 | |||

| 80 | 20000 | 24100 | 63 | 160 | |||

| 144 | 4500 | 32500 | 41200 | 7100 | 5500 | 70 | 360 |

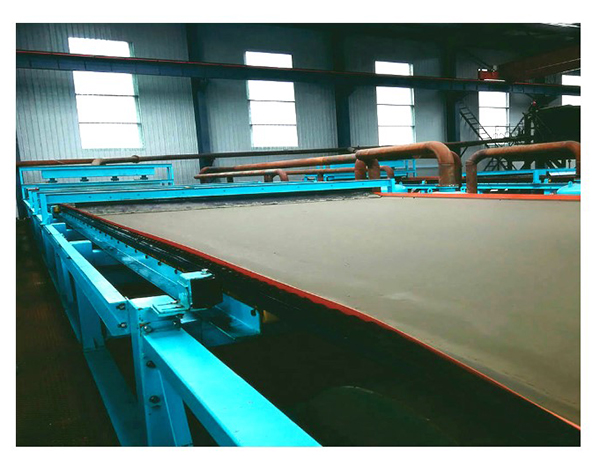

Inkqubo yoMzobo wokuHamba

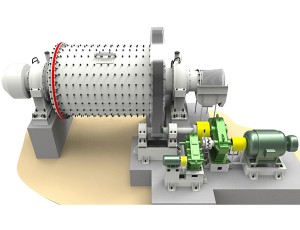

Amacandelo Angundoqo

Iifoto zeendawo ezisebenzayo