Inkqubo yokomisa izinto zokufuma okuPhezulu

Inkqubo yokomisa izinto zokufuma okuPhezulu

Inkcazo yezinto

Eyona ndlela iqhelekileyo yokulahla umgquba wemfuyo kukuthengisa njengomgquba wasefama ngexabiso eliphantsi kwaye usetyenziswe ngokuthe ngqo njengesichumiso sezolimo, ixabiso laso kwezoqoqosho alinakujongwa ngokupheleleyo kwaye lisetyenziswe.Ngapha koko, ezi zizixhobo ezixabisekileyo zefula kunye nezichumiso, ukuba zinokuphuhliswa kwaye zisetyenziswe, ziya kuba nentsingiselo enkulu kwimveliso ye-organic fertilizer, kuphuhliso lweshishini lokutyala kunye nokuzala, ukukhuthaza imveliso yezolimo kunye nengeniso, ukonga amandla kunye ukutya okuluhlaza okungangcolisekiyo, uphuhliso lwezolimo oluluhlaza, ukukhuselwa kwendalo kunye nempilo yabantu.

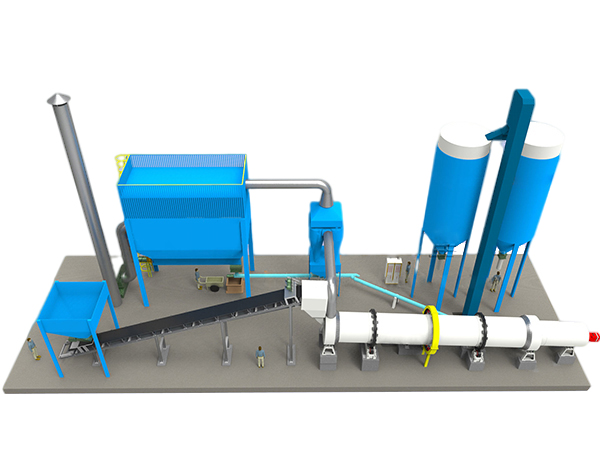

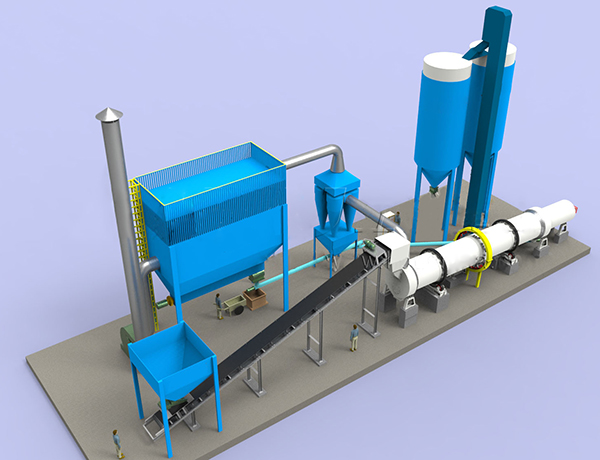

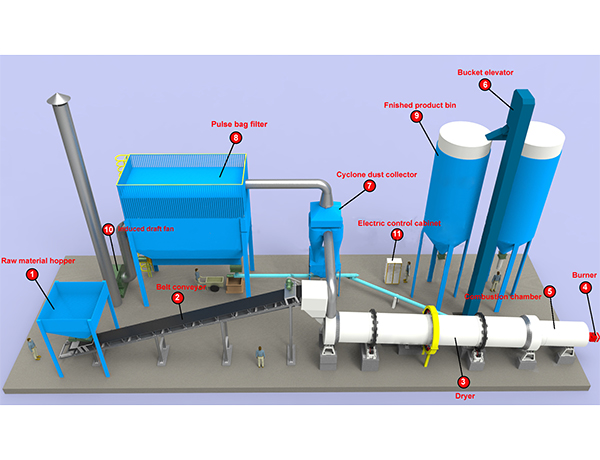

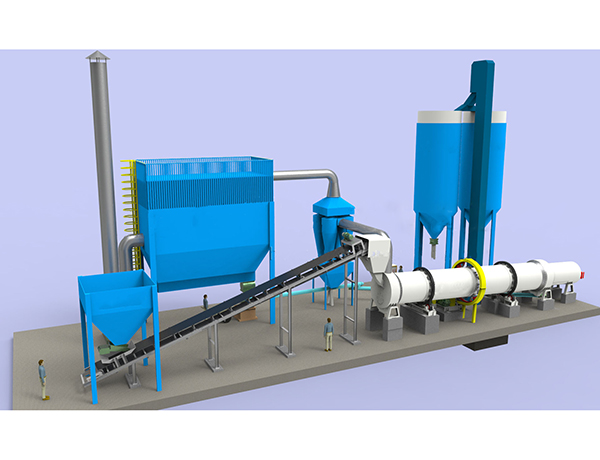

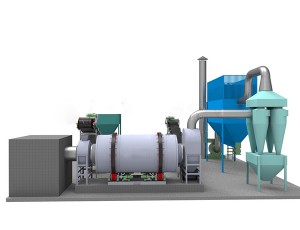

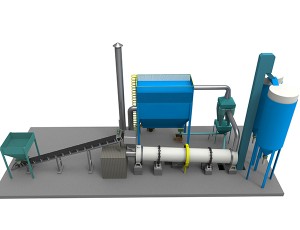

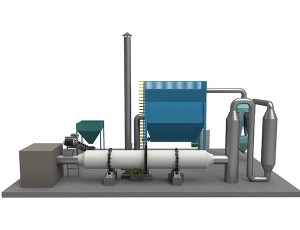

Inkqubo Flow

Izinto ezigalelwe amanzi ziya kuthuthelwa kwintloko yokomisa nge-screw conveyor emva kokusasazwa, kwaye emva koko iya kuthunyelwa ngaphakathi kwesomisi ngokusebenzisa i-spiral yokutywina engenamandla yesondlo (iteknoloji yelungelo elilodwa lomenzi wenkampani yethu), kwaye idlule kwiindawo ezininzi. iindawo zokusebenza ezilandelayo emva kokungena kwindawo yokomisa:

1. Izinto ezikhokelela kwindawo

Izinto ziya kudibana nobushushu obuphezulu boxinzelelo lomoya ongalunganga emva kokungena kule ndawo kwaye amanzi amaninzi aya kuba ngumphunga ngokukhawuleza, kwaye imathiriyeli ayinakubunjwa ibe yinto encangathi phantsi kokushukunyiswa kwepleyiti enkulu yokuphakamisa i-engile.

2. Indawo yokucoca

Umkhusane wezinto eziphathekayo uya kwenziwa ngelixa i-sludge iphakanyiselwe phezulu kule ndawo, kwaye iya kubangela intonga yezinto kudonga lwesilinda ngelixa iwa phantsi, kwaye isixhobo sokucoca sifakwe kule ndawo (Isimbo sokuphakamisa isitya sokuvusa, uhlobo lwe-X lwesibini. ixesha lokuvuselela isitya, ikhonkco elichaphazelayo, ipleyiti enefuthe), izinto eziphathekayo zinokususwa ngokukhawuleza eludongeni lwesilinda ngesixhobo sokucoca, kunye nesixhobo sokucoca sinokutyumza izinto ezidityanisiweyo kunye, ukwenzela ukwandisa indawo yokutshintsha ubushushu, ukunyuka. ixesha lokutshintshana kobushushu, ugweme ukuveliswa kwesiganeko somoya wetonela, ukuphucula izinga lokumisa;

3. Indawo yepleyiti yokunyusela

Le ndawo yindawo yokomisa iqondo lokushisa eliphantsi, i-slime yale ndawo iphantsi komswakama ophantsi kunye nemeko ekhululekile, kwaye akukho nto yokubambelela kule ndawo, iimveliso ezigqityiweyo zifikelela kwiimfuno zokufuma emva kokutshintshiselwa kobushushu, kwaye emva koko zingene ekugqibeleni. indawo yokulahla;

4. Indawo yokukhupha

Azikho iipleyiti ezishukumisayo kule ndawo yesilinda esomisi, kwaye imathiriyeli iya kuqengqeleka kwizibuko lokukhupha.Izinto eziphathekayo ngokuthe ngcembe zikhululeka emva kokumisa, kwaye zikhutshwe ekupheleni kokukhupha, kwaye emva koko zithunyelwe kwindawo echongiweyo ngesixhobo sokuhambisa, kunye nothuli olucolekileyo olutsalwa kunye nerhasi yomsila luqokelelwa ngumqokeleli wothuli.

Umoya oshushu ungena kumatshini wokomisa usuka ekupheleni kokutya, kwaye iqondo lobushushu liyancitshiswa ngokuthe ngcembe ngaxeshanye lokuhanjiswa kobushushu, kwaye umphunga wamanzi ukhutshelwe ngaphandle phantsi kokufunxwa kwedrafti yedrafti yefeni, emva koko ikhutshwe emoyeni emva kokulungiswa. .

Izinto eziluncedo kwiNkqubo

Ukusebenza okuphezulu kwe-thermal, ixabiso eliphantsi lokomisa

Isakhiwo esitsha sangaphakathi, kunye nokomeleza ukucocwa kwezinto ezihlakaziweyo kunye nokuqhutyelwa kobushushu, ukuphelisa into enamathele yodonga lwangaphakathi lomzimba we-barrel, ukulungelelanisa ngakumbi ukufuma kwezinto kunye nokunamathela, indawo yokutshintsha ubushushu kunye nokusebenza kokumisa kuyanda.Iiparamitha zokusebenza zingatshintshwa ngokwezinto ezahlukeneyo, kwaye ukutshintshwa kobushushu bezinto eziphathekayo kwi-dryer kugcwele ngokupheleleyo.

Ukubaleka okuthembekileyo, ukuzinza okulungileyo

Uhlobo olutsha lokutya kunye nokukhutshwa kwesixhobo, luphelisa ukwenzeka kweplagi ekutyaleni, ukungaqhubeki, i-nonuniform kunye nokubuyiswa kwezinto."Isixhobo sokulungelelanisa" samkelwe sisisomisi, esenza ukuba ukutsalwa kunye neringi ihlale isenza unxibelelwano olusondeleyo, kwaye inciphisa kakhulu i-abrasion kunye nokusetyenziswa kwamandla. i-abrasion yesondo yegiya kunye nevili elixhasayo, umsebenzi we-cylinder uzinzile kwaye unokwethenjelwa.

Uluhlu olubanzi lomthombo wobushushu usebenzisa, ukukhuselwa kwendalo kunye nokungangcoliseki

Amalahle, i-oyile, irhasi yendalo, irhasi yepetroleum engamanzi ingasetyenziswa njengamafutha.Imiselwa ngokweemfuno zemathiriyeli kunye nezibonelelo zendalo zasekhaya, ukuphucula ukusebenza kakuhle kwemveliso kunye neenzuzo zoqoqosho.

Inqanaba eliphezulu lokuzenzekelayo, ukhuseleko lwexesha langempela

Inkqubo yokulawula ngokuzenzekelayo ye-PLC ingamkelwa kuyo yonke inkqubo, inkqubo iqulethe izixhobo zokuvavanya eziphambili: ukulinganisa ubushushu, ukulawulwa kweqondo lokushisa (inokulungiswa nangaliphi na ixesha ngokweemfuno zezinto), umsebenzi we-alarm yephutha ngokuzenzekelayo, ngokuzenzekelayo. ukhuseleko lokuvala, njl.

Iiparamitha zobuGcisa

| Umzekelo | Idayamitha yesilinda(mm) | Ubude besilinda(mm) | Umthamo wesilinda(m3) | Isantya se-Cylinder rotary (r/min) | Amandla(kW) | Ubunzima(t) |

| VS 0.6x5.8 | 600 | 5800 | 1.7 | 1-8 | 3 | 2.9 |

| VS 0.8x8 | 800 | 8000 | 4 | 1-8 | 4 | 3.5 |

| VS 1x10 | 1000 | 10000 | 7.9 | 1-8 | 5.5 | 6.8 |

| VS 1.2x5.8 | 1200 | 5800 | 6.8 | 1-6 | 5.5 | 6.7 |

| VS 1.2x8 | 1200 | 8000 | 9 | 1-6 | 5.5 | 8.5 |

| VS 1.2x10 | 1200 | 10000 | 11 | 1-6 | 7.5 | 10.7 |

| VS 1.2x11.8 | 1200 | 11800 | 13 | 1-6 | 7.5 | 12.3 |

| VS 1.5x8 | 1500 | 8000 | 14 | 1-5 | 11 | 14.8 |

| VS 1.5x10 | 1500 | 10000 | 17.7 | 1-5 | 11 | 16 |

| VS 1.5x11.8 | 1500 | 11800 | 21 | 1-5 | 15 | 17.5 |

| VS 1.5x15 | 1500 | 15000 | 26.5 | 1-5 | 15 | 19.2 |

| VS 1.8x10 | 1800 | 10000 | 25.5 | 1-5 | 15 | 18.1 |

| VS 1.8x11.8 | 1800 | 11800 | 30 | 1-5 | 18.5 | 20.7 |

| VS 1.8x15 | 1800 | 15000 | 38 | 1-5 | 18.5 | 26.3 |

| VS 1.8x18 | 1800 | 18000 | 45.8 | 1-5 | 22 | 31.2 |

| VS 2x11.8 | 2000 | 11800 | 37 | 1-4 | 18.5 | 28.2 |

| VS 2x15 | 2000 | 15000 | 47 | 1-4 | 22 | 33.2 |

| VS 2x18 | 2000 | 18000 | 56.5 | 1-4 | 22 | 39.7 |

| VS 2x20 | 2000 | 20000 | 62.8 | 1-4 | 22 | 44.9 |

| VS 2.2x11.8 | 2200 | 11800 | 44.8 | 1-4 | 22 | 30.5 |

| VS 2.2x15 | 2200 | 15000 | 53 | 1-4 | 30 | 36.2 |

| VS 2.2x18 | 2200 | 18000 | 68 | 1-4 | 30 | 43.3 |

| VS 2.2x20 | 2200 | 20000 | 76 | 1-4 | 30 | 48.8 |

| VS 2.4x15 | 2400 | 15000 | 68 | 1-4 | 30 | 43.7 |

| VS 2.4x18 | 2400 | 18000 | 81 | 1-4 | 37 | 53 |

| VS 2.4x20 | 2400 | 20000 | 91 | 1-4 | 37 | 60.5 |

| VS 2.4x23.6 | 2400 | 23600 | 109 | 1-4 | 45 | 69.8 |

| VS 2.8x18 | 2800 | 18000 | 111 | 1-3 | 45 | 62 |

| VS 2.8x20 | 2800 | 20000 | 123 | 1-3 | 55 | 65 |

| VS 2.8x23.6 | 2800 | 23600 | 148 | 1-3 | 55 | 70 |

| VS 2.8x28 | 2800 | 28000 | 172 | 1-3 | 75 | 75 |

| VS 3x20 | 3000 | 20000 | 141 | 1-3 | 55 | 75 |

| VS 3x23.6 | 3000 | 23600 | 170 | 1-3 | 75 | 85 |

| VS 3x28 | 3000 | 28000 | 198 | 1-3 | 90 | 91 |

| VS 3.2x23.6 | 3200 | 23600 | 193 | 1-3 | 90 | 112 |

| VS 3.2x32 | 3200 | 32000 | 257 | 1-3 | 110 | 129 |

| VS 3.6x36 | 3600 | 36000 | 366 | 1-3 | 132 | 164 |

| VS 3.8x36 | 3800 | 36000 | 408 | 1-3 | 160 | 187 |

| VS 4x36 | 4000 | 36000 | 452 | 1-3 | 160 | 195 |

Iifoto zeNdawo eziSebenzayo