I-VSPF eStacked Filter Press

I-VSPF eStacked Filter Press

Iimpawu zeZixhobo

sebenzisa ubume obupakishwe kwiipleyiti, sebenzisa isixhobo esincedisayo ukwenza umsebenzi uzinze ngakumbi.

● Dibanisa ukuhluza, ukukhupha, ukuvasa, ukomisa umoya, ukukhupha ikeyiki kunye nokuhlamba amalaphu kunye.

● Uxinzelelo lwe-extrusion ukuya kwi-1.6MPa, lusetyenziswa ngokubanzi kwintsimi eneemfuno ezahlukeneyo zokufuma kwekhekhe.

● 4.sebenzisa inkqubo yokulawula i-hydraulic drive, yenza umsebenzi uzinzile kunye nokusetyenziswa kwamandla aphantsi.

● Hlanganisa i-PLC, i-HMI kunye nenkqubo yokulawula izixhobo njl.njl ezikrelekrele kunye, yenza isihluzo sisebenze ngakumbi kwaye sibe lula.

● Sebenzisa isixhobo sokucoca amanzi anoxinzelelo oluphezulu ukwenza ukuba ukuhlamba amalaphu kusebenze ngakumbi.

● Uyilo ngegumbi lesetyhula, ulwakhiwo olunengqiqo ngakumbi, ukusebenza kakuhle kugqame ngakumbi.

Umgaqo wokuSebenza

1, Ukuhluza: xa iqela iipleyiti ivaliwe, ukumpompa uludaka lokucoca, sebenzisa ithumbu esasazwayo ukutyisa uludaka kwigumbi ngalinye ludaka, kunye filtrate badlule ngelaphu ukuhluza isakhelo kwaye akhuphe ngaphandle, okuqinileyo kwakheka ikeyiki phezu komhlaba ilaphu.

2

3, Ukuhlanjwa kwekeyiki: ukuhlamba amanzi okutyisa kwigumbi eludaka ngokusebenzisa isigqubuthelo sombhobho osasaziweyo kwikhekhe ngokupheleleyo, phantsi koxinzelelo, amanzi okuhlamba adlula kwikhekhe kunye nelaphu ukuze aphume.

4, Ukomiswa komoya: umoya ocinezelweyo ngokutya okuthululweyo kwigumbi eliludaka kunye nokucofa irabha idiaphragm, yenza amanzi anoxinzelelo oluphezulu kwidiaphragm yerabha ukuba aphume, kwaye umoya ocinezelweyo udlule kwikhekhe kwaye ukhuphe ulwelo ngaphandle ukuze unciphise ukufuma kwekeyiki ukuya. elona nqanaba lisezantsi.

5, Ukukhupha ikeyiki: xa ugqibile inkqubo yokomisa umoya, vula iqela leepleyiti, inkqubo yokuqhuba yenza ilaphu libaleke kwaye ikeyiki ikhuphe kumacala omabini esihluzo ngaxeshanye.

Qaphela: Nceda ngokweemeko zokwenyani zokusebenzisa ukulungisa amaxesha e-extrusion kunye nenkqubo yokomisa umoya.

Inkqubo yoMzobo wokuHamba

Uthotho lwezixhobo

Inkcazo yobuGcisa

| Umzekelo/VSPFⅠ | VSPFⅠ-1 | VSPFⅠ-2 | VSPFⅠ-3 |

| Indawo yesihluzi/m2 | 1 | 2 | 3 |

| Ubungakanani bepleyiti/mm | 0.5m2/ umaleko | ||

| Icwecwe elinesiqingatha / umaleko | 2 | 4 | 6 |

| Ubude/m | 2.5 | ||

| Ububanzi/m | 1.5 | ||

| Ubude/m | 2 | 2.2 | 2.5 |

| Ubunzima/T | 8 | 9 | 10 |

| Amandla esikhululo samanzi/KW | 7.5 | ||

| Intloko yepompo yokwandisa/m | 167 | ||

| Umyinge wempompo yokwandisa m3/h | 8 | ||

| Amandla empompo yokwandisa/KW | 7.5 | ||

IDatha yesiXhobo esiNcedisayo

| Umbhobho wokuhlamba impompo yentloko/m | 70 | ||

| Ipompo yokuhlamba imibhobho ihamba ngem3/h | 10 | ||

| Intloko yepompo yokuhlamba ilaphu/m | 70 | ||

| Impompo yokuvasa amalaphu ihamba ngem3/h | 10 | ||

| Ipompo yokutyisa uludaka ngentloko/m | 70 | ||

| Impompo yokuhambisa amanzi ngodaka m3/h | Ngokutsho data ludaka ukukhetha | ||

| Uxinzelelo lokomisa umoya/Mpa | 0.8 | ||

| I-air compressor flowrate yokomisa umoya m3/min | 0.5 | 1 | 1.5 |

| Umthamo wetanki yokomisa umoya/m3 | 1 | 2 | 3 |

| Uxinzelelo lomoya lwezixhobo/Mpa | 0.7 | ||

| I-air compressor flowrate yezixhobo m3 / min | 0.3 | ||

| Izixhobo umthamo wetanki yomoya/m3 | 0.5 | ||

| Phawula: idimension yesixhobo sisisiseko, kodwa hayi isayizi yeenkcukacha, ngoko ke lo bungakanani busenzelwa ireferensi.Izinto ezahlukeneyo zepleyiti, isihluzi siya kuba nobude obahlukeneyo kunye nobunzima.Idata yezixhobo ezincedisayo nje ngereferensi, iya kutshintsha ngokusebenza kohluzo kwi-slurry eyahlukileyo. | |||

Inkcazo yobuGcisa

| Umzekelo | VSPFⅡ-3 | VSPFⅡ-6 | VSPFⅡ-9 | VSPFⅡ-12 | VSPFⅡ-15 | VSPFⅡ-18 | VSPFⅡ-21 | VSPFⅡ-24 |

| indawo yokucoca/m2 | 3 | 6 | 9 | 12 | 15 | 18 | 21 | 24 |

| ubungakanani bepleyiti/mm | 1.5m2/ umaleko | |||||||

| ipleyiti Qty/ umaleko | 2 | 4 | 6 | 8 | 10 | 12 | 14 | 16 |

| ubude/m | 3.7 | |||||||

| ububanzi/m | 4.1 | |||||||

| ubude/m | 2.6 | 2.8 | 3.2 | 3.7 | 4.2 | 4.6 | 5.1 | 5.5 |

| ubunzima/T | 12 | 13 | 14 | 15 | 16 | 17 | 18 | 19 |

| Amandla esikhululo se-hydraulic/KW | 11 | |||||||

| Intloko yepompo yokwandisa/m | 28 | |||||||

| Impompo yempompo yokwandisa i-m3/h | 136 Qaphela: ukuba uxinzelelo lwe-extrusion lungaphezulu kwe-1.3MPa, le datha yi-164 | |||||||

| Amandla empompo yokwandisa/KW | 11 Qaphela: ukuba uxinzelelo lwe-extrusion lungaphezulu kwe-1.3MPa, le datha yi-15 | |||||||

IDatha yesiXhobo esiNcedisayo

| Intloko yempompo yokuhlamba imibhobho /m | 68 | |||||||

| Umbhobho wokuhlamba impompo yempompo3/h | 20 | |||||||

| Intloko yepompo yokuhlamba ilaphu/m | 70 | |||||||

| Impompo yokuhlambela amalaphu flowrate m3/h | 12 | |||||||

| Ipompo yokutyisa uludaka ngentloko/m | 70 | |||||||

| Impompo yokuhambisa amanzi ngodaka m3/h | Ngokutsho data ludaka ukukhetha | |||||||

| Uxinzelelo lokomisa umoya/Mpa | 0.8 | |||||||

| Ukuqukuqela kwecompressor yomoya yokomisa umoya m3/min | Ngokutsho data ludaka ukukhetha | |||||||

| Umthamo wetanki yokomisa umoya/m3 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 |

| Uxinzelelo lomoya lwezixhobo/Mpa | 0.7 | |||||||

| Ukuqukuqela kwecompressor yomoya kwizixhobo m3/min | 0.5 | |||||||

| Izixhobo umthamo wetanki yomoya/m3 | 1 | |||||||

| Phawula: idimension yesixhobo sisisiseko, kodwa hayi isayizi yeenkcukacha, ngoko ke lo bungakanani busenzelwa ireferensi.Izinto ezahlukeneyo zepleyiti, isihluzi siya kuba nobude obahlukeneyo kunye nobunzima.Idata yezixhobo ezincedisayo nje ngereferensi, iya kutshintsha ngokusebenza kohluzo kwi-slurry eyahlukileyo. | ||||||||

Inkcazo yobuGcisa

| Umzekelo VSPFⅢ | VSPFⅢ-18 | VSPFⅢ-24 | VSPFⅢ-30 | VSPFⅢ-36 | VSPFⅢ-42 | VSPFⅢ-48 | VSPFⅢ-54 | VSPFⅢ-60 | VSPFⅢ-66 |

| indawo yokucoca/m2 | 18 | 24 | 30 | 36 | 42 | 48 | 54 | 60 | 66 |

| ubungakanani bepleyiti/mm | 3.0m2/umaleko | ||||||||

| ipleyiti Qty/ umaleko | 6 | 8 | 10 | 12 | 14 | 16 | 18 | 20 | 22 |

| ubude/m | 5.1 | ||||||||

| ububanzi/m | 5.5 | ||||||||

| ubude/m | 4.3 | 4.5 | 4.9 | 5.4 | 5.8 | 6.3 | 6.8 | 7.2 | 7.7 |

| ubunzima/T | 31 | 33 | 35 | 37 | 39 | 41 | 43 | 45 | 47 |

| isikhululo se-hydraulic powerKW | 22 | ||||||||

| Intloko yepompo yokwandisa/m | 40 | 55 | |||||||

| Impompo yempompo yokwandisa i-m3/h | 136 Qaphela: ukuba uxinzelelo lwe-extrusion lungaphezulu kwe-1.3MPa, le datha yi-162 | 135 Qaphela: ukuba uxinzelelo lwe-extrusion lungaphezulu kwe-1.3MPa, le datha yi-166 | |||||||

| Amandla empompo yokwandisa/KW | 15 Qaphela: ukuba uxinzelelo lwe-extrusion lungaphezulu kwe-1.3MPa, le datha yi-18.5 | 22 Qaphela: ukuba uxinzelelo lwe-extrusion lungaphezulu kwe-1.3MPa, le datha yi-30 | |||||||

IDatha yesiXhobo esiNcedisayo

| Umbhobho wokuhlamba impompo yentloko/m | 65 | ||||||||

| Ipompo yokuhlamba imibhobho ihamba ngem3/h | 26 | ||||||||

| Intloko yepompo yokuhlamba ilaphu/m | 70 | ||||||||

| Impompo yokuvasa amalaphu ihamba ngem3/h | 16 | ||||||||

| Ipompo yokutyisa uludaka ngentloko/m | 70 | ||||||||

| Impompo yokuhambisa amanzi ngodaka m3/h | Ngokutsho data ludaka ukukhetha | ||||||||

| Uxinzelelo lokomisa umoya/Mpa | 0.8 | ||||||||

| I-air compressor flowrate yokomisa umoya m3/min | Ngokutsho data ludaka ukukhetha | ||||||||

| Umthamo wetanki yokomisa umoya/m3 | 8 | 10 | 10 | 12 | 12 | 15 | 15 | 20 | 20 |

| Uxinzelelo lomoya lwezixhobo/Mpa | 0.7 | ||||||||

| I-air compressor flowrate yezixhobo m3 / min | 0.5 | ||||||||

| Izixhobo umthamo wetanki yomoya/m3 | 1 | ||||||||

| Phawula: idimension yesixhobo sisisiseko, kodwa hayi isayizi yeenkcukacha, ngoko ke lo bungakanani busenzelwa ireferensi.Izinto ezahlukeneyo zepleyiti, isihluzi siya kuba nobude obahlukeneyo kunye nobunzima.Idata yezixhobo ezincedisayo nje ngereferensi, iya kutshintsha ngokusebenza kohluzo kwi-slurry eyahlukileyo. | |||||||||

Inkcazo yobuGcisa

| Umzekelo VSPFⅣ | VSPFⅣ-60 | VSPFⅣ-72 | VSPFⅣ-84 | VSPFⅣ-96 | VSPFⅣ-108 | VSPFⅣ-120 | VSPFⅣ-132 | VSPFⅣ-144 | VSPFⅣ-156 | VSPFⅣ-168 |

| Indawo yokucoca/m2 | 60 | 72 | 84 | 96 | 108 | 120 | 132 | 144 | 156 | 168 |

| Ubungakanani bepleyiti/mm | 6m2/ umaleko | |||||||||

| Icwecwe elinguQty/ umaleko | 10 | 12 | 14 | 16 | 18 | 20 | 22 | 24 | 26 | 28 |

| Ubude/m | 7.1 | |||||||||

| Ububanzi/m | 5.5 | |||||||||

| Ubude/m | 5.4 | 5.8 | 6.2 | 6.6 | 6.9 | 7.2 | 7.6 | 7.9 | 8.3 | 8.6 |

| Ubunzima/T | 92 | 96 | 100 | 104 | 108 | 112 | 116 | 120 | 124 | 128 |

| Amandla esikhululo samanzi/KW | 30 | 37 | ||||||||

| Intloko yepompo yokwandisa/m | 110 | 150 | ||||||||

| Impompo yempompo yokwandisa i-m3/h | 126 Qaphela: ukuba uxinzelelo lwe-extrusion lungaphezulu kwe-1.3MPa, le datha yi-168 | 128 Qaphela: ukuba uxinzelelo lwe-extrusion lungaphezulu kwe-1.3MPa, le datha yi-162.5 | ||||||||

| Amandla empompo yokwandisa/KW | 37 Qaphela: ukuba uxinzelelo lwe-extrusion lungaphezulu kwe-1.3MPa, le datha yi-45 | 55 Qaphela: > 1.3MPa, le datha ngama-75 | ||||||||

IDatha yesiXhobo esiNcedisayo

| Umbhobho wokuhlamba impompo yentloko/m | 72 | |||||||||

| Umbhobho wokuhlamba impompo yempompo3/h | 36 | |||||||||

| Intloko yepompo yokuhlamba ilaphu/m | 70 | |||||||||

| Impompo yokuhlambela amalaphu flowrate m3/h | 20 | |||||||||

| Ipompo yokutyisa uludaka ngentloko/m | 70 | |||||||||

| Impompo yokuhambisa amanzi ngodaka m3/h | Ngokutsho data ludaka ukukhetha | |||||||||

| Uxinzelelo lokomisa umoya/Mpa | 0.8 | |||||||||

| Ukuqukuqela kwecompressor yomoya yokomisa umoya m3/min | Ngokutsho data ludaka ukukhetha | |||||||||

| Umthamo wetanki yokomisa umoya/m3 | 20 | 20 | 25 | 30 | 35 | 35 | 40 | 40 | 45 | 45 |

| Uxinzelelo lomoya lwezixhobo/Mpa | 0.7 | |||||||||

| Ukuqukuqela kwecompressor yomoya kwizixhobo m3/min | 1 | |||||||||

| Izixhobo umthamo wetanki yomoya/m3 | 2 | |||||||||

| Phawula: idimension yesixhobo sisisiseko, kodwa hayi isayizi yeenkcukacha, ngoko ke lo bungakanani busenzelwa ireferensi.Izinto ezahlukeneyo zepleyiti, isihluzi siya kuba nobude obahlukeneyo kunye nobunzima.Idata yezixhobo ezincedisayo nje ngereferensi, iya kutshintsha ngokusebenza kohluzo kwi-slurry eyahlukileyo. | ||||||||||

Iinkalo zeSicelo

Isetyenziswa ngokubanzi kugutyulo olusezidolophini, kushicilelo lwelaphu kunye nokudaya, i-electroplate, ukwenza iphepha, isikhumba, ukutywala, ukusetyenzwa kokutya, ukuhlanjwa kwamalahle, ishishini lepetrochemical, chemistry, metallurgy, ulwahlulo lweminerali, ikhemesti, i-ceramic industry dewatering dewatering njalo njalo. imveliso yeshishini ukwahlula okuqinileyo-ulwelo okanye inkqubo yolwelo lokuvuza.

| Hayi. | Igama lesixhobo | Ukuqina kokutya (g/l) | Extrusion water ressure (MPa) | Ubunzima bekeyiki (mm) | Ukufuma kwekeyiki (%) | Umthamo kg/m2.h |

| 1 | 4A-zeolite | 150-295 | 1.4 | 35 | 19-22 | 190-200 |

| 2 | Isulfure | ≈50 | 1.2 | 30 | 30 | 120 |

| 3 | Inkokeli | ≈50 | 1.2 | 30 | 15-20 | 35 |

| 4 | I-slag yobhedu | 600 | 1.6 | 40 | 8~9 | 310 |

| 5 | Inkunkuma yamanzi sulphate | 80 | 1.6 | 45 | 28–35 | 120-175 |

| 6 | Calcination iintsalela zegolide | 300 | 1.6 | 35 | 14–18 | 300~340 |

| 7 | Superfine aluminiyam hydroxide | 15-20% | 1.6 | 20 | 29.5~32 | 65 |

| 8 | Cu-Ni yoxinaniso | 66.7 | 1.6 | 30 | 9.78 | 257 |

| 9 | Ugxininiso lobhedu | 45~50 | 1.6 | 35 | 7.6 | 360 |

| 10 | Ni ugxininise | 45~50 | 1.6 | 30 | 8 | 300~400 |

| 11 | I-Tantalum-niobium ivumba | 1.6 | 20–25 | 200 | ||

| 12 | I-slime yamalahle | 30-35% | 1.6 | 30 | 16 ~ 17 | 300 |

| 14 | Iimisila zegolide emva kokudada | 20-30% | 1.6 | 35 | 12-18 | 300 |

| 15 | IMannitol | 1.5 | 12 | 35 | ||

| 16 | Zinc oxide powder | 57% | 1.6 | 18 | 20 | 90 |

| 17 | I-Leaching intsalela ye-zinc oxide | 50% | 1.6 | 10 | 18-20 | 70 |

| 18 | I-sulfure igxininise | 10% | 1.6 | 20 | 25~35 | 200 |

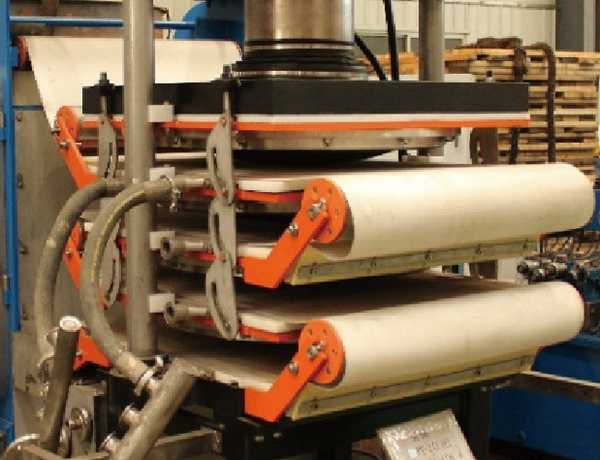

Ulwakhiwo lweZixhobo

Ulwakhiwo lweQela lecwecwe

Ukuvelisa Imifanekiso

Amacandelo Angundoqo

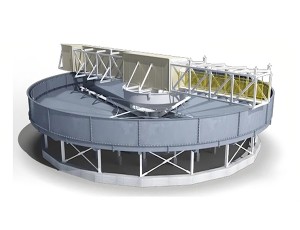

Ukusebenzisa iSiza