High Humidity Material Drying System

High Humidity Material Drying System

Incazelo Yento

Indlela evamile yokulahla umquba wemfuyo ukuthengisa njengomquba wasepulazini ngentengo ephansi futhi usetshenziswe ngokuqondile njengomanyolo wezolimo, ukubaluleka kwawo kwezomnotho akufanele kuhlolwe ngokuphelele futhi kusetshenziswe.Eqinisweni, lezi yimithombo yefolishi eyigugu kanye nomanyolo, uma ingathuthukiswa futhi isetshenziswe, izoba nokubaluleka okukhulu ekukhiqizeni umanyolo we-organic, ekuthuthukisweni kwemboni yokutshala nokuzalanisa, ukukhuthaza ukukhiqizwa kwezolimo kanye nemali engenayo, ukonga amandla kanye ukudla okuluhlaza okungangcolisiwe, ukuthuthukiswa kwezolimo eziluhlaza, ekuvikelweni kwemvelo kanye nempilo yabantu.

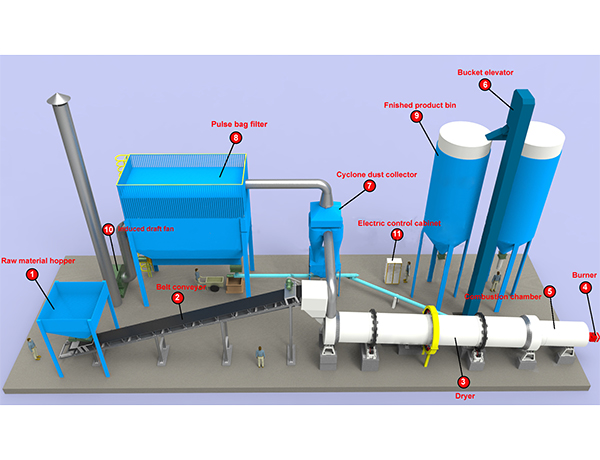

Ukugeleza Kwenqubo

Izinto ezincishisiwe zizothuthelwa ekhanda lokomisa nge-screw conveyor ngemva kokusakazwa, bese kuthunyelwa ngaphakathi kwesomiso ngokusebenzisa isiphakeli esingenawo amandla sokubopha uphawu (ubuchwepheshe belungelo lobunikazi benkampani yethu), futhi sidlule ezindaweni eziningi. izindawo zokusebenza ezilandelayo ngemuva kokungena ku-dryer:

1. Indawo ehamba phambili

Izinto ezisetshenziswayo zizohlangana nezinga lokushisa eliphezulu komoya ocindezelayo ngemva kokungena kule ndawo futhi amanzi amaningi azohwamuka ngokushesha, futhi okubalulekile ngeke kwakhiwe izinto ezinamathelayo ngaphansi kokunyakaziswa kwepuleti elikhulu lokuqondisa i-engeli.

2. Indawo yokuhlanza

Ikhethini lempahla lizokwakhiwa ngenkathi i-sludge iphakanyiswa kule ndawo, futhi izobangela ukuthi into ethile inamathele odongeni lwesilinda ngenkathi iwa, futhi idivayisi yokuhlanza ifakwe kule ndawo (Isitayela sokuphakamisa ipuleti elishukumisayo, uhlobo lwesekhondi elingu-X ipuleti elinyakazayo, iketango elinomthelela, ipuleti elinomthelela), okokusebenza kungasuswa ngokushesha odongeni lwesilinda ngedivayisi yokuhlanza, futhi idivayisi yokuhlanza ingaphinda icoboze izinto ezihlanganiswe ndawonye, ukuze kwandiswe indawo yokushintshanisa ukushisa, kwandiswe. isikhathi sokushintshaniswa kokushisa, gwema ukukhiqizwa kwesimo somhubhe womoya, uthuthukise izinga lokumisa;

3. Indawo yamapuleti okuphakamisayo ethambekele

Le ndawo iyindawo yokomisa izinga lokushisa eliphansi, i-slime yale ndawo isesimweni somswakama ophansi kanye nesimo esixekethile, futhi akukho mkhuba wokunamathela kule ndawo, imikhiqizo eqediwe ifinyelela izidingo zomswakama ngemva kokushintshaniswa kokushisa, bese ingena ekugcineni. indawo yokuphumula;

4. Indawo yokukhipha amanzi

Awekho amapuleti anyakazayo kule ndawo yesilinda esomisile, futhi okokusebenza kuzobe kugingqika embobeni yokukhipha amanzi.Impahla kancane kancane iyaxega ngemva kokumiswa, futhi ikhishwe ekugcineni kokukhipha, bese ithunyelwa endaweni eqokiwe idivayisi yokudlulisa, futhi uthuli olucolile olukhishwa kanye negesi yomsila luqoqwa umqoqi wothuli.

Umoya oshisayo ungena emshinini wokomisa usuka ekugcineni kokuphakelayo, futhi izinga lokushisa liyancishiswa kancane kancane ngesikhathi esifanayo sokudluliswa kokushisa kwe-convection, futhi isitimu samanzi sikhishwe ngaphansi kokumuncwa kwe-fan yokusalungiswa, bese sikhishelwa emoyeni ngemva kokucubungula. .

Izinzuzo Zesistimu

Ukusebenza kahle kokushisa okuphezulu, izindleko eziphansi zokumisa

Isakhiwo esisha sangaphakathi, futhi siqinise ukuhlanzwa kwezinto ezihlakazekile kanye nokuqhutshwa kokushisa, ukuqeda into yokunamathela yodonga lwangaphakathi lomzimba womgqomo, kuvumelana nezimo kumswakama wezinto ezibonakalayo nokunamathela, indawo yokushintshanisa ukushisa kanye nokusebenza kahle kokumisa kuyanda.Imingcele yokusebenza ingashintshwa ngokusho kwezinto ezihlukene, futhi ukushintshaniswa kokushisa kwento ekomisweni kugcwele ngokugcwele.

Ukugijima okuthembekile, ukuzinza okuhle

Uhlobo olusha lwedivayisi yokuphakela nokukhipha, luqede ukwenzeka kwepulaki ekuphakeleni, ukungaqhubeki, okungeyona iyunifomu nokubuya kwezinto ezibonakalayo."Idivayisi yerola yokuqondanisa" yamukelwa umshini wokomisa, okwenza indandatho yokudonsa neginqikayo ihlale yenza ukuthintana komugqa, futhi kunciphisa kakhulu ukuhuzuka kanye nokusetshenziswa kwamandla. "I-zero thrust evundlile" yokomisa iyabonakala, okunciphisa kakhulu ukuhuzuka kwesondo legiya kanye nesondo elisekelayo, ukusebenza kwesilinda kuzinzile futhi kuthembekile.

Uhlu olubanzi lomthombo wokushisa osetshenziswayo, ukuvikelwa kwemvelo nokungangcolisi

Amalahle, uwoyela, igesi yemvelo, igesi ye-petroleum ewuketshezi ingasetshenziswa njengophethiloli.Kunqunywa ngokuya ngezidingo zezinto ezibonakalayo kanye nezinzuzo zemvelo zasendaweni, ukuthuthukisa ukusebenza kahle kokukhiqiza kanye nezinzuzo zezomnotho.

Izinga eliphezulu lokuzenzakalela, ukuphepha kwesikhathi sangempela

Uhlelo lokulawula okuzenzakalelayo lwe-PLC lungamukelwa kulo lonke uhlelo, uhlelo luqukethe imishini yokuhlola ethuthukisiwe: ukulinganisa izinga lokushisa, ukulawulwa kwezinga lokushisa (lingalungiswa nganoma yisiphi isikhathi ngokuya ngezidingo zezinto), umsebenzi we-alamu yephutha elizenzakalelayo, othomathikhi. ukuvikelwa kokuvala shaqa, njll.

Imingcele Yezobuchwepheshe

| Imodeli | Ububanzi besilinda(mm) | Ubude besilinda(mm) | Ivolumu yesilinda(m3) | Isivinini se-cylinder rotary (r/min) | Amandla(kW) | Isisindo(t) |

| VS 0.6x5.8 | 600 | 5800 | 1.7 | 1-8 | 3 | 2.9 |

| VS 0.8x8 | 800 | 8000 | 4 | 1-8 | 4 | 3.5 |

| VS 1x10 | 1000 | 10000 | 7.9 | 1-8 | 5.5 | 6.8 |

| VS 1.2x5.8 | 1200 | 5800 | 6.8 | 1-6 | 5.5 | 6.7 |

| VS 1.2x8 | 1200 | 8000 | 9 | 1-6 | 5.5 | 8.5 |

| VS 1.2x10 | 1200 | 10000 | 11 | 1-6 | 7.5 | 10.7 |

| VS 1.2x11.8 | 1200 | 11800 | 13 | 1-6 | 7.5 | 12.3 |

| VS 1.5x8 | 1500 | 8000 | 14 | 1-5 | 11 | 14.8 |

| VS 1.5x10 | 1500 | 10000 | 17.7 | 1-5 | 11 | 16 |

| VS 1.5x11.8 | 1500 | 11800 | 21 | 1-5 | 15 | 17.5 |

| VS 1.5x15 | 1500 | 15000 | 26.5 | 1-5 | 15 | 19.2 |

| VS 1.8x10 | 1800 | 10000 | 25.5 | 1-5 | 15 | 18.1 |

| VS 1.8x11.8 | 1800 | 11800 | 30 | 1-5 | 18.5 | 20.7 |

| VS 1.8x15 | 1800 | 15000 | 38 | 1-5 | 18.5 | 26.3 |

| VS 1.8x18 | 1800 | 18000 | 45.8 | 1-5 | 22 | 31.2 |

| VS 2x11.8 | 2000 | 11800 | 37 | 1-4 | 18.5 | 28.2 |

| VS 2x15 | 2000 | 15000 | 47 | 1-4 | 22 | 33.2 |

| VS 2x18 | 2000 | 18000 | 56.5 | 1-4 | 22 | 39.7 |

| VS 2x20 | 2000 | 20000 | 62.8 | 1-4 | 22 | 44.9 |

| VS 2.2x11.8 | 2200 | 11800 | 44.8 | 1-4 | 22 | 30.5 |

| VS 2.2x15 | 2200 | 15000 | 53 | 1-4 | 30 | 36.2 |

| VS 2.2x18 | 2200 | 18000 | 68 | 1-4 | 30 | 43.3 |

| VS 2.2x20 | 2200 | 20000 | 76 | 1-4 | 30 | 48.8 |

| VS 2.4x15 | 2400 | 15000 | 68 | 1-4 | 30 | 43.7 |

| VS 2.4x18 | 2400 | 18000 | 81 | 1-4 | 37 | 53 |

| VS 2.4x20 | 2400 | 20000 | 91 | 1-4 | 37 | 60.5 |

| VS 2.4x23.6 | 2400 | 23600 | 109 | 1-4 | 45 | 69.8 |

| VS 2.8x18 | 2800 | 18000 | 111 | 1-3 | 45 | 62 |

| VS 2.8x20 | 2800 | 20000 | 123 | 1-3 | 55 | 65 |

| VS 2.8x23.6 | 2800 | 23600 | 148 | 1-3 | 55 | 70 |

| VS 2.8x28 | 2800 | 28000 | 172 | 1-3 | 75 | 75 |

| VS 3x20 | 3000 | 20000 | 141 | 1-3 | 55 | 75 |

| VS 3x23.6 | 3000 | 23600 | 170 | 1-3 | 75 | 85 |

| VS 3x28 | 3000 | 28000 | 198 | 1-3 | 90 | 91 |

| VS 3.2x23.6 | 3200 | 23600 | 193 | 1-3 | 90 | 112 |

| VS 3.2x32 | 3200 | 32000 | 257 | 1-3 | 110 | 129 |

| VS 3.6x36 | 3600 | 36000 | 366 | 1-3 | 132 | 164 |

| VS 3.8x36 | 3800 | 36000 | 408 | 1-3 | 160 | 187 |

| VS 4x36 | 4000 | 36000 | 452 | 1-3 | 160 | 195 |

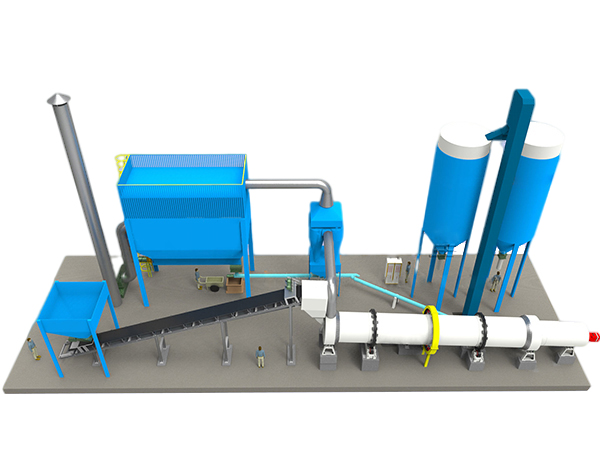

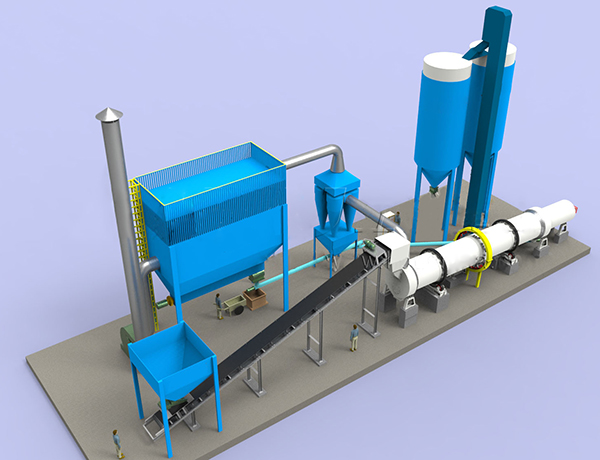

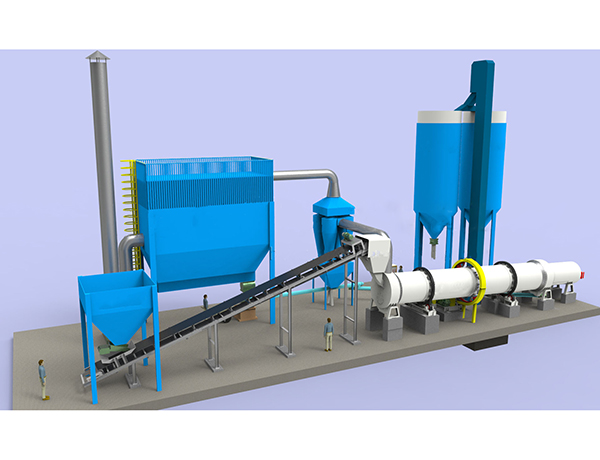

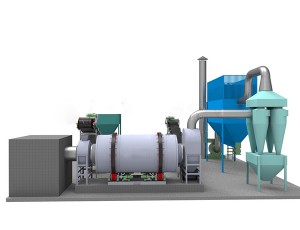

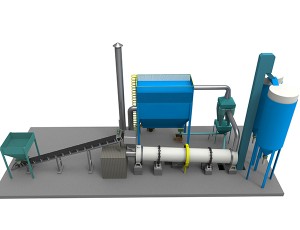

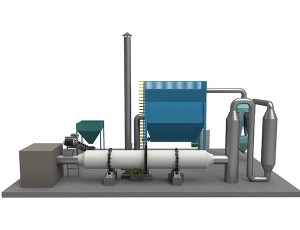

Izithombe Zezindawo Zokusebenza