I-Light Material Drying System yokukhiqiza

I-Light Material Drying System yokukhiqiza

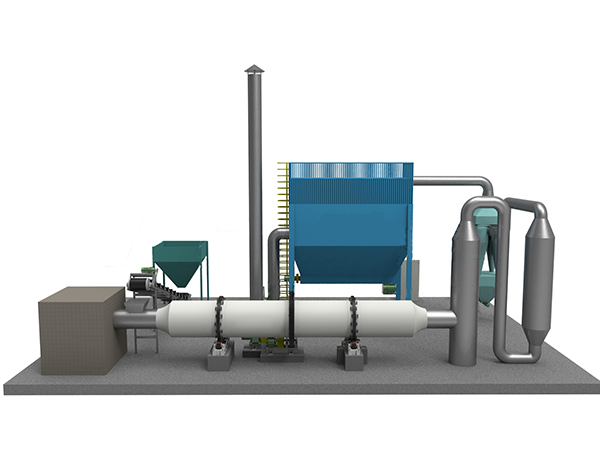

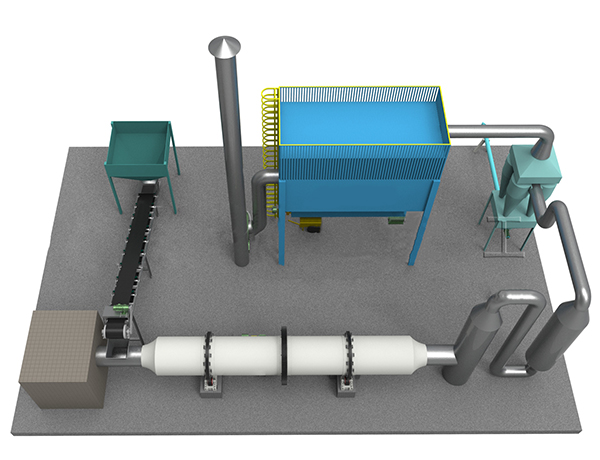

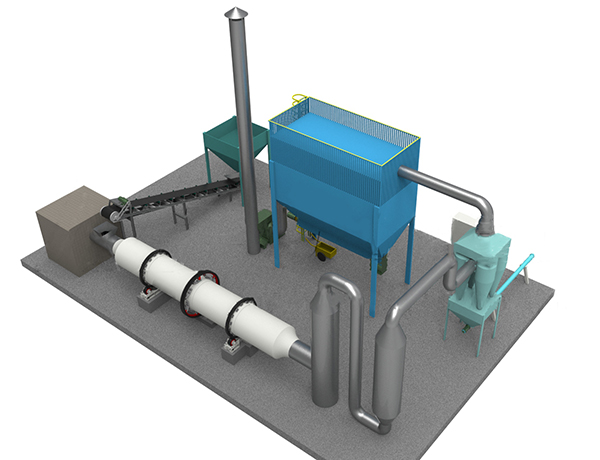

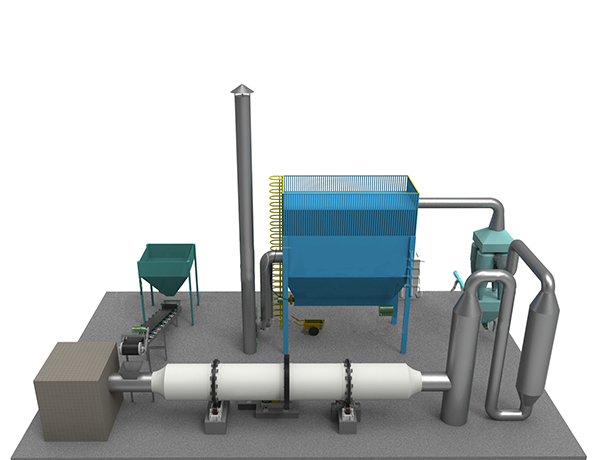

Isingeniso Sesistimu

Eminyakeni yamuva nje, ngokwanda kwemithombo yezemvelo, ukusetshenziswa okuphelele kwamandla e-biomass sekubaluleke kakhulu kithi.Ngenxa yokuqukethwe okuphezulu komswakama we-sawdust, izinkuni eziphukile, eziholela ekushiseni okungaphelele, okuholela ekutheni inhlansi ishise isikhwama sothuli ngemuva kwesitshalo esomile, esingabangeli kuphela ukukhishwa ngokweqile, kodwa futhi nezindleko eziphezulu. ukushintsha isikhwama sothuli.Enqubweni yokukhiqiza imikhiqizo yezinkuni kanye namafutha e-biomass anenani eliphezulu lokuvutha okuvuthayo, ama-chips ezinkuni kanye nama-dregs aphukile kuyadingeka ukwenza inqubo yokomisa.

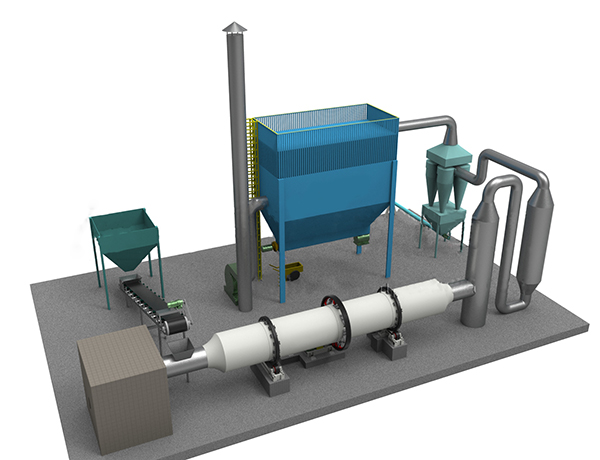

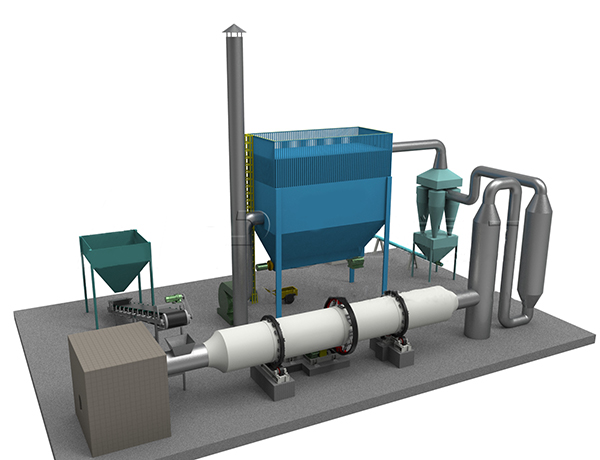

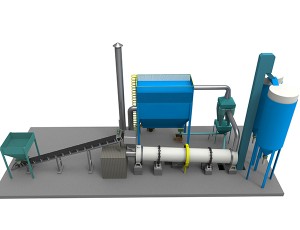

Ukugeleza Kwenqubo

Ngemva kokuphakelwa ku-hopper, ngaphansi komsebenzi we-gravity impahla eluhlaza izowela ku-conveyor yebhande elibekwe ngaphansi kwe-hopper, bese-ke ezodluliselwa emshinini wokuhlola, ubukhulu, i-strip kanye nezinye izinto ezingajwayelekile zizohanjiswa. ihlukaniswe ngemva kokuhlolwa, futhi izinhlayiya ezifanayo zizohanjiswa ekupheleni kokuphakela kwesomiso (Isilinda esisodwa noma isomisi se-cylinder emithathu sizokhethwa ngokwesimo sesevisi) ngumthumeli webhande ngaphansi komshini wokuhlola.Ukuphela kokuphakelayo kwesomisi kuxhunywe nomthombo wokushisa futhi isiphetho sokukhipha sixhunywe namapayipi omoya we-pulse.Udonga lomlilo luzofakwa esitofini sokuqhuma okushisayo ukuze kuqinisekiswe ukuphepha kwenqubo yokomisa, ukuqeda ukwenzeka kwezinto ezishiswa isomisi, futhi ukushisa okudlula ipayipi kuzofakwa phakathi kwesitofu esishisayo nesitofu. isomisi njengengxenye yesigcinalwazi sokushisa.Izinto ezisetshenziswayo zizolethwa epayipini le-pulse eliguquliwe ngobubanzi ngemva kokomiswa kanye nokuphelelwa amanzi emzimbeni okokuqala ngqa ngaphakathi kwesomisi, okuzoba sesimweni esibilisayo esimisiwe kububanzi obukhulu bepayipi le-pulse, bese yomiswa ngokushesha. ngemuva kokuxhumana nomoya wokushisa ophelile ovela kumshini wokomisa.Futhi impahla izokhishwa epayipini le-pulse yimimoya enamandla futhi ihanjiswe esigabeni sokuqala sokuqoqa isiphepho lapho okuqukethwe kwayo kwamanzi kufinyelela imfuneko yokuklama, futhi u-80% wezinto ezomisiwe zizoqoqwa, bese ungena esigabeni sesibili somqoqi wesiphepho. ngemva kokudlula ifeni yokusalungiswa eyenzelwe ukuqoqa okokusebenza kwesokunxele.Umqoqi wesigaba sesibili sesivunguvungu ungathathelwa indawo umqoqi wothuli wohlobo lwesikhwama.

Izinzuzo Zesistimu

Amandla okomisa aqinile anesikhathi esifushane sokumisa

Isistimu yokomisa izinto ezikhanyayo inomklamo othuthukisiwe, ovumela ukuthi izinto zibe nokuxhumana okugcwele kumshini wokomisa, indawo egcwele yezinhlayiya iyindawo ephumelelayo yokomisa, futhi inamandla okumisa Okujulile.Ngomshini wokomisa umoya we-pulse, isikhathi sokumisa siyingxenye yesomiso esijwayelekile, ukusebenza kahle komshini wokomisa kukhuphuka kakhulu.

Izindleko eziphansi zokomisa ngekhono eliphezulu lokumisa

Isistimu yokomisa impahla ekhanyayo inesakhiwo esithuthukisiwe, esinendawo encane embozwe yinxanxathela yezitolo, kulula ukwakha nokwenza ukunakekelwa.Ukusebenza kahle kwe-thermal kungafinyelela ku-90% uma yomisa amanzi angaboshiwe.

Umphumela omuhle wokumisa ngezinga eliphezulu lokuzenzekelayo

Umswakamo wokugcina uzinzile (10% -13%) ngemva kokuba okokukhanya okujwayelekile komisiwe, futhi okomisiwe akuqukethe ukungcola.I-hot blast stove ingafaniswa ne-alamu yokushisa ephezulu, idivayisi yokuqapha ilangabi, i-alamu ye-temering, idivayisi yokuhlukanisa uphethiloli, engaqinisekisa ukuphepha kokuvutha.

Imingcele Yezobuchwepheshe

| Imodeli | Ububanzi besilinda(mm) | Ubude besilinda(mm) | Ivolumu yesilinda(m3) | Isivinini se-cylinder rotary (r/min) | Amandla(kW) | Isisindo(t) |

| VS0.6x5.8 | 600 | 5800 | 1.7 | 1-8 | 3 | 2.9 |

| VS0.8x8 | 800 | 8000 | 4 | 1-8 | 4 | 3.5 |

| VS1x10 | 1000 | 10000 | 7.9 | 1-8 | 5.5 | 6.8 |

| VS1.2x5.8 | 1200 | 5800 | 6.8 | 1-6 | 5.5 | 6.7 |

| VS1.2x8 | 1200 | 8000 | 9 | 1-6 | 5.5 | 8.5 |

| VS1.2x10 | 1200 | 10000 | 11 | 1-6 | 7.5 | 10.7 |

| VS1.2x11.8 | 1200 | 11800 | 13 | 1-6 | 7.5 | 12.3 |

| VS1.5x8 | 1500 | 8000 | 14 | 1-5 | 11 | 14.8 |

| VS1.5x10 | 1500 | 10000 | 17.7 | 1-5 | 11 | 16 |

| VS1.5x11.8 | 1500 | 11800 | 21 | 1-5 | 15 | 17.5 |

| VS1.5x15 | 1500 | 15000 | 26.5 | 1-5 | 15 | 19.2 |

| VS1.8x10 | 1800 | 10000 | 25.5 | 1-5 | 15 | 18.1 |

| VS1.8x11.8 | 1800 | 11800 | 30 | 1-5 | 18.5 | 20.7 |

| VS1.8x15 | 1800 | 15000 | 38 | 1-5 | 18.5 | 26.3 |

| VS1.8x18 | 1800 | 18000 | 45.8 | 1-5 | 22 | 31.2 |

| VS2x11.8 | 2000 | 11800 | 37 | 1-4 | 18.5 | 28.2 |

| VS2x15 | 2000 | 15000 | 47 | 1-4 | 22 | 33.2 |

| VS2x18 | 2000 | 18000 | 56.5 | 1-4 | 22 | 39.7 |

| VS2x20 | 2000 | 20000 | 62.8 | 1-4 | 22 | 44.9 |

| VS2.2x11.8 | 2200 | 11800 | 44.8 | 1-4 | 22 | 30.5 |

| VS2.2x15 | 2200 | 15000 | 53 | 1-4 | 30 | 36.2 |

| VS2.2x18 | 2200 | 18000 | 68 | 1-4 | 30 | 43.3 |

| VS2.2x20 | 2200 | 20000 | 76 | 1-4 | 30 | 48.8 |

| VS2.4x15 | 2400 | 15000 | 68 | 1-4 | 30 | 43.7 |

| VS2.4x18 | 2400 | 18000 | 81 | 1-4 | 37 | 53 |

| VS2.4x20 | 2400 | 20000 | 91 | 1-4 | 37 | 60.5 |

| VS2.4x23.6 | 2400 | 23600 | 109 | 1-4 | 45 | 69.8 |

| VS2.8x18 | 2800 | 18000 | 111 | 1-3 | 45 | 62 |

| VS2.8x20 | 2800 | 20000 | 123 | 1-3 | 55 | 65 |

| VS2.8x23.6 | 2800 | 23600 | 148 | 1-3 | 55 | 70 |

| VS2.8x28 | 2800 | 28000 | 172 | 1-3 | 75 | 75 |

| VS3x20 | 3000 | 20000 | 141 | 1-3 | 55 | 75 |

| VS3x23.6 | 3000 | 23600 | 170 | 1-3 | 75 | 85 |

| VS3x28 | 3000 | 28000 | 198 | 1-3 | 90 | 91 |

| VS3.2x23.6 | 3200 | 23600 | 193 | 1-3 | 90 | 112 |

| VS3.2x32 | 3200 | 32000 | 257 | 1-3 | 110 | 129 |

| VS3.6x36 | 3600 | 36000 | 366 | 1-3 | 132 | 164 |

| VS3.8x36 | 3800 | 36000 | 408 | 1-3 | 160 | 187 |

| VS4x36 | 4000 | 36000 | 452 | 1-3 | 160 | 195 |

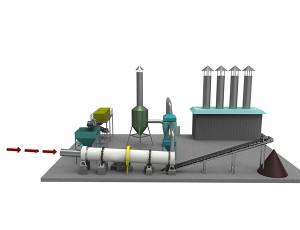

Izithombe Zezindawo Zokusebenza