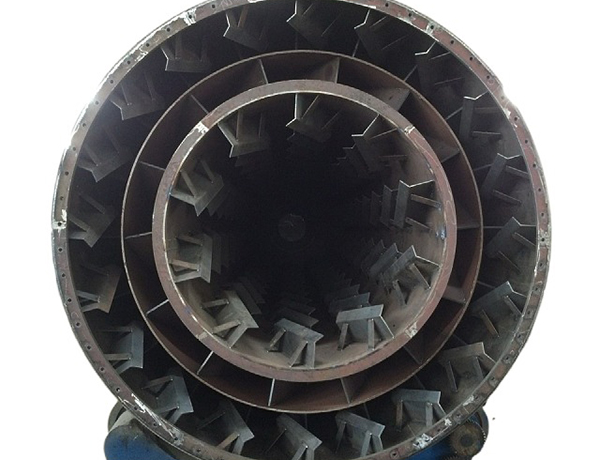

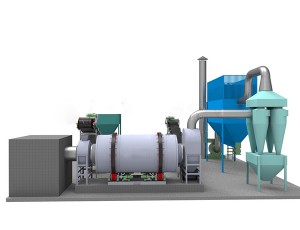

Three Cylinder noma Drum Dryer

Three Cylinder noma Drum Dryer

Izimpawu Zokusebenza

1. Izinga lokushisa eliphansi lokukhipha umoya, impilo ende yesevisi yemishini yokususa uthuli.

2. Ubukhulu bezinto zesigaxa, izinhlayiya, nezimpushana zingaphansi kuka-20mm zingomiswa.

3. Ukushayela igiya akudingekile futhi kushayelwa ngokuqondile i-roller, esebenza kahle kakhulu.

4. Ngaphandle kwesimo sokuvuza komoya, ubunzima bokuvalwa buyaxazululwa ngokuphelele, futhi ukufakwa kungaqedwa phakathi namahora ambalwa.

5. 50% wamakhava endawo ancishisiwe uma kuqhathaniswa nokomisa imigqomo eyodwa, futhi ukutshalwa kwezimali komhlaba kwehliswe ngo-50%, ukusetshenziswa kwamandla kwehle ngo-60%.

6. I-self-insulation thermal ukusebenza kahle kwe-three-cylinder dryer ingafinyelela ngaphezu kwama-70% (i-self-insulation ukusebenza kahle kwe-thermal yendabuko yesigubhu esisodwa kuphela ngama-35%), inomphumela omangalisayo wokonga.

7. Izinkomba zokugcina zomswakama zingalawulwa kalula ngokuvumelana nesicelo.

8. Ngaphansi kuka-1% womswakama wezinto ezibonakalayo ungaqinisekiswa ngesomisi esinamasilinda amathathu, okuwumkhiqizo okhethwayo wodaka olomile oluxubile kanye nomugqa wokukhiqiza impuphu ye-slag.

9. Izinga lokushisa lempahla ekhishiwe lingu-<50 ℃, elingadluliselwa ngokuqondile esiseleni sokugcina, kungenasidingo sokupholisa eshedini lokupholisa.

Isimiso Sokusebenza

Izinto ezisetshenziswayo zingena esigubhuni esijikelezayo sangaphakathi zisuka kudivayisi yokuphakelayo, ukubona ukomiswa komfula, izinto zokwakha ziphakanyiswa phezulu naphansi njalo ngamapuleti okuphakamisa ungqimba lwangaphakathi futhi ukushintshaniswa kokushisa kutholwa ngaphansi kokunyakaza okuvunguzayo, izinto ziya kolunye uhlangothi. yesilinda esingaphakathi bese singena kusilinda esimaphakathi, nezinto ziyaphakanyiswa bese ziyiswa phambili kusilinda esiphakathi, ngendlela yezinyathelo ezimbili ukuya phambili nesinyathelo esisodwa emuva, izinto ezisetshenziswayo zimunca ukushisa kokubili okuvela kusilinda esingaphakathi naphakathi. I-cylinder, ngakolunye uhlangothi, isikhathi sokumisa siyandiswa, futhi izinto ezisetshenziswayo zifinyelela isimo esihle sokumisa kulesi sigaba.I-Material ihambisa enye ingxenye yesilinda esiphakathi bese ingena ku-cylinder yangaphandle, izinto ezomisiwe zikhishwa ngokushesha ku-cylinder ngaphansi komsebenzi womoya oshisayo.

Imingcele Yezobuchwepheshe

| Imodeli | Idatha yesilinda | Amandla (t/h) | Isivinini se-cylinder rotary (r/min) | Amandla (kW) | ||||

| Ububanzi besilinda sangaphandle (m) | Ubude besilinda sangaphandle (m) | Ivolumu yesilinda (m3) | Umfula isihlabathi | Fly umlotha | I-Slag | |||

| I-VS6203 | 1.6 | 1.8 | 3.6 | 2-3 | 1-2 | 1-2 | 3-10 | 4 |

| VS6205 | 2 | 2 | 6.28 | 4-5 | 2-3 | 3-4 | 3-10 | 5.5 |

| VS6210 | 2.2 | 2.5 | 9.5 | 8-10 | 4-5 | 6-8 | 3-10 | 7.5 |

| VS6215 | 2.5 | 2.8 | 13.7 | 12-15 | 7-8 | 10-12 | 3-10 | 11 |

| VS2x4 | 2 | 4 | 12.56 | 8-12 | 4-6 | 8-10 | 3-10 | 3x2 |

| VS2x5 | 2 | 5 | 15.7 | 12-15 | 6-7 | 10-13 | 3-10 | 4x2 |

| VS2x6 | 2 | 6 | 18.84 | 20-25 | 10-17 | 20-27 | 3-10 | 7.5x2 |

| VS2.2x4.5 | 2.2 | 4.5 | 17.09 | 14-18 | 7-9 | 12-15 | 3-10 | 5.5x2 |

| VS2.5x6 | 2.5 | 6.5 | 31.89 | 23-28 | 10-13 | 20-22 | 3-10 | 5.5x4 |

| VS2.7x7 | 2.7 | 7 | 40.5 | 30-35 | 20-25 | 27-45 | 3-10 | 7.5x4 |

| VS2.8x6 | 2.8 | 6 | 36.9 | 30-35 | 15-18 | 25-30 | 3-10 | 5.5x4 |

| VS3x6 | 3 | 6 | 42.39 | 35-40 | 18-20 | 32-35 | 3-10 | 7.5x4 |

| VS3x7 | 3 | 7 | 49.46 | 40-45 | 20-25 | 35-40 | 3-10 | 7.5x4 |

| VS3.2x7 | 3.2 | 7 | 56.26 | 45-50 | 25-30 | 40-45 | 3-10 | 11x4 |

| VS3.2x8 | 3.2 | 8 | 64.3 | 50-55 | 30-35 | 45-50 | 3-10 | 11x4 |

| VS3.6x8 | 3.6 | 8 | 81.38 | 60-70 | 35-40 | 60-65 | 3-10 | 15x4 |

| VS3.8x9 | 3.8 | 9 | 102 | 70-80 | 40-45 | 70-75 | 3-10 | 15x4 |

| VS4x10 | 4 | 10 | 125.6 | 90-100 | 45-50 | 80-90 | 3-10 | 18.5x4 |

| VS4.2x8.5 | 4.2 | 8.5 | 117.7 | 80-100 | 45-60 | 80-90 | 3-10 | 18.5x4 |

Ukukhiqiza Nokucubungula

Umkhiqizo Oqediwe

Ukuvakashelwa Kwekhasimende

Ukulethwa

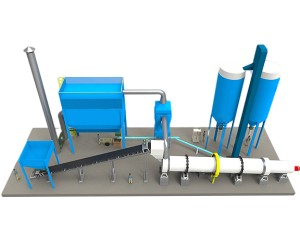

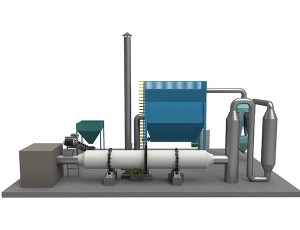

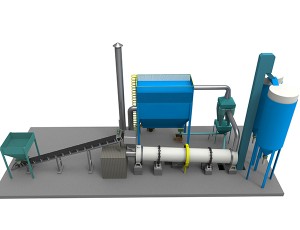

Izithombe Zezindawo Zokusebenza